4.6.2025 / Lecture en 5 minutes

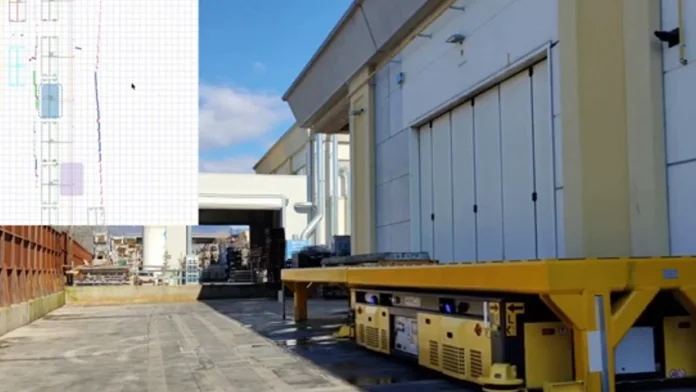

AGV de 40 tonnes pour le transport de tôles d'acier - Automated Factory Logistics Solution

Aperçu du projet

Cet AGV lourd de 40 tonnes a été conçu sur mesure pour l'industrie sidérurgique, afin de relever le défi du transport automatisé de plaques d'acier surdimensionnées (longueur de plus de 27 mètres, poids de plus de 40 tonnes) dans des environnements à haute température et à forte teneur en poussières.

Il intègre la navigation SLAM par laser, la coordination de plusieurs véhicules et la stabilisation des charges lourdes pour remplacer la manutention manuelle ou par chariot élévateur, ce qui permet de créer des boucles logistiques intelligentes dans les usines.

Paramètres de base

| Paramètres | Spécifications |

|---|---|

| Capacité de charge | 40 tonnes, personnalisable jusqu'à 100 tonnes |

| Précision de la navigation | ±10mm (mode Laser SLAM) |

| Méthode de navigation | SLAM laser/bande magnétique/guidage optique (en option) |

| Conduire | Roues omnidirectionnelles ou entraînement différentiel (pour un rayon de braquage ≥ 300 mm dans les allées étroites) |

| Sécurité | Radar laser d'évitement d'obstacles à 360° + prévention mécanique des collisions + arrêt d'urgence (temps de réponse < 0,3 seconde) |

| Environnement | Température 0~50°C / Humidité 40%~80% / Environnement poussiéreux / Protection IP54 |

| Batterie | 24 heures de fonctionnement continu (prise en charge de la recharge hybride hydrogène-électricité/sans fil) |

Le défi

- Efficacité sans pilote: Éliminez les manipulations manuelles dans la logistique des grands volumes.

- Intégration de l'AGV: Synchroniser les ascenseurs avec les protocoles de navigation et de chargement des AGV.

- Conformité en matière de sécurité: Assure un fonctionnement sans faille pour les charges lourdes (jusqu'à 2000 kg).

- Environnement difficile Résilience: Fonctionne dans des conditions intérieures/extérieures de -20°C à 60°C.

Solutions

- Stabilisation des charges lourdes

- La suspension de qualité aérospatiale maintient l'inclinaison de la cargaison à moins de 1° sur un sol irrégulier ;

- L'entraînement coopératif multi-moteurs réduit le balancement à ≤±5mm pendant le démarrage et l'arrêt ("ballet mécanique").

- Navigation robuste

- Le SLAM laser + la compensation visuelle maintiennent une précision de ±15 mm dans la poussière.

- Le mode bande magnétique résiste à l'abrasion du laitier d'acier (durée de vie >10 ans).

- Manutention des cargaisons surdimensionnées

- Synchronisation double AGV activée par la 5G (erreur de levage/mouvement <10mm)13 ;

- La planification dynamique des trajectoires réduit le rayon de braquage des plaques de 27 m de 40%

Avantages

✅ Renforcement de la sécurité

- Triple protection (radar + mechanical + E-stop) cuts accident rate by 98%15;

- Version antidéflagrante disponible pour les environnements inflammables.

✅ Une avancée en matière d'efficacité

- La planification sans personnel réduit le temps de cycle logistique de 70%.

- L'intégration MES/WMS permet une livraison de matériel à 99,9% dans les délais.

✅ Optimisation des coûts

- Remplace 10 travailleurs + 3 chariots élévateurs avec un retour sur investissement <2 ans.

- La version hydrogène réduit les coûts énergétiques de 52% par rapport au diesel