9.9.2025 / Lecture en 5 minutes

Tour à composants lourds de 8 tonnes - Équipement de tournage de précision pour la fabrication d'engrenages

Vue d'ensemble

Cette analyse de cas porte sur une machine de tournage lourde de 8 tonnes.

Spécialement conçu pour le traitement de précision de composants lourds tels que roues électriquesIl relève le défi du positionnement multi-angle pour les grandes pièces à engrenages pendant l'usinage grâce à un système de positionnement multi-angle. plate-forme innovante à rainures en U et un système d'outils multiples.

Paramètres de base

| Paramètres | Valeur/Description |

|---|---|

| Charge nominale | 8000 kg |

| Taille de la plate-forme | 2000*2000+2000*2000mm |

| Angle de rotation | 90 degrés |

| Vitesse de rotation | <50 secondes/cycle |

| Puissance d'entraînement | Moteur réducteur 3KW de marque SEW |

| Matériau du cadre principal | Profilé d'acier J200*100*6 |

| Épaisseur de la plate-forme | 8 mm |

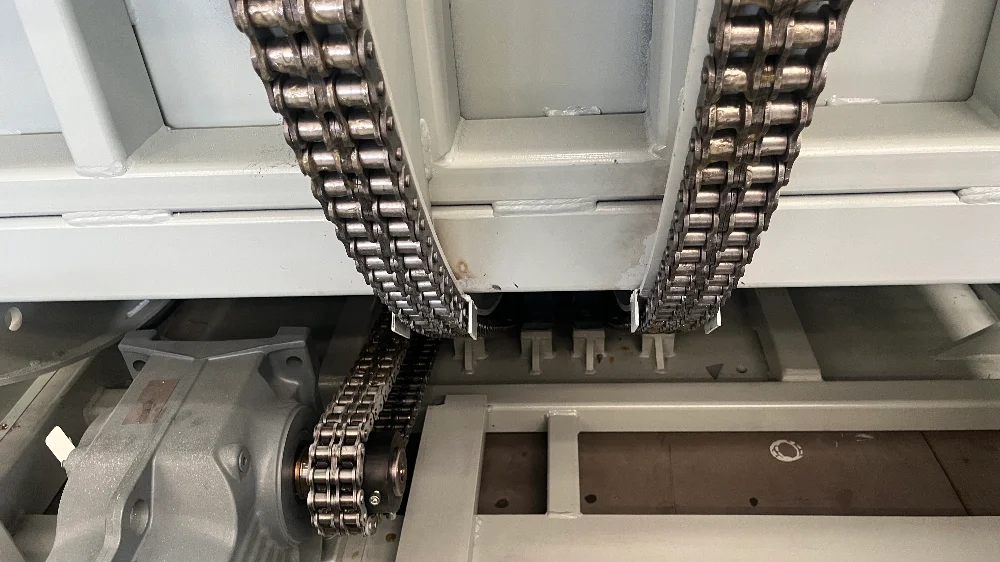

| Spécification de la chaîne | 20A-2 |

| Système de contrôle | Composants Schneider electric |

| Couleur de l'équipement | RAL7035 |

Comment ça marche

L'équipement utilise un système de transmission par chaîne entraîné par un motoréducteur pour obtenir une rotation précise de la plate-forme à 90 degrés.

Une plate-forme comporte des rainures en U et des rainures en T personnalisées, tandis que l'autre est équipée de rainures en V amovibles et de dispositifs de tension pour s'adapter aux différentes spécifications des pièces à usiner.

Les opérateurs contrôlent le système à l'aide d'une boîte à boutons portative externe dotée d'une fonction de commande par impulsions.

Les défis

- Les composants de grande taille, comme les roues électriques, présentent des risques pour la sécurité lors des manœuvres manuelles.

- Les équipements de tournage conventionnels ne peuvent pas répondre aux exigences de positionnement de précision

- Des spécifications différentes requièrent des méthodes de serrage et de fixation variées

- Les processus de fabrication nécessitent des rotations multiples et un positionnement précis

- Les difficultés de mobilité et d'ajustement des équipements affectent la flexibilité de l'aménagement des ateliers

Solutions

- Positionnement de précision: La conception de l'outillage multiple rainure en U + rainure en T + rainure en V assure la stabilité de la pièce.

- Fonctionnement sûr: Le système d'entraînement SEW avec commande électrique Schneider garantit la fiabilité opérationnelle

- Tournage efficaceRotation de 90 degrés en 50 secondes pour améliorer l'efficacité de la production

- Conception mobile: Les fentes pour chariots élévateurs dans la base facilitent le repositionnement de l'équipement

- Adaptation polyvalente: Les gorges en V et les tendeurs amovibles s'adaptent aux différents besoins des pièces à usiner.

- Assurance de la sécuritéLa sangle de verrouillage de 8 tonnes avec fonction d'auto-verrouillage assure la sécurité des opérations.