9.18.2025 / Lecture en 5 minutes

Ascenseurs à mouvement alternatif parallèles de 5 tonnes dans une usine de production de carbone de Mongolie intérieure

Vue d'ensemble

Cette analyse de cas détaille la solution de manutention pour une entreprise de transport de marchandises. "L'usine de l'extinction des feux dans la région autonome de Mongolie intérieure.

Pour transporter efficacement les produits finis blocs de carbone entre deux ateliers présentant des différences de niveau significatives à un rythme de production rapide, deux ascenseurs parallèles à mouvement alternatif ont été déployés.

Depuis sa mise en service le 15 août 2025, le système a fonctionné de manière fiable dans des conditions de haute fréquence et d'utilisation intensive, sans aucun problème affectant la production.

Paramètres de base

| Paramètres | Valeur |

|---|---|

| Modèle | SJLT5.0-5.0 |

| Charge nominale | 5000 kg |

| Taille de la voiture | 2200×2200×1200 mm |

| Taille de la plate-forme | 2200×2200 mm |

| Espace requis | 3200×2600 mm |

| Hauteur de déplacement | 5000 mm |

| Vitesse de levage | 0-30 m/min (moyenne ~20 m/min sur 5 m en raison de l'accélération) |

| Stations | 2 arrêts, 2 stations |

| Précision du positionnement | ±15 mm |

| Unité d'entraînement | Moteur SEW 22KW/380V (K107DRN180L4/BE30/V-22KW) |

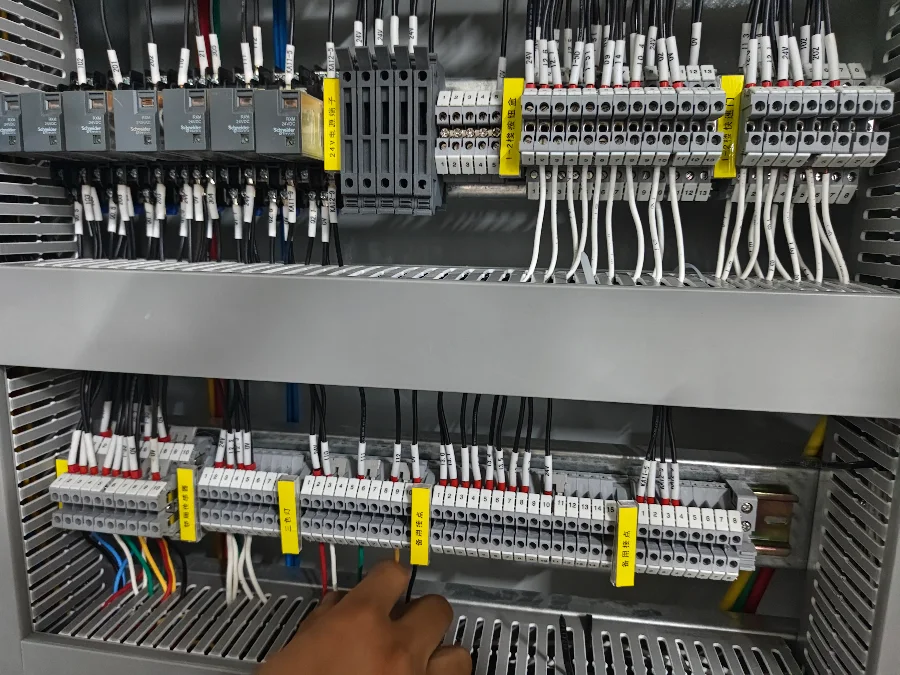

| Système de contrôle | PLC (interfaces de communication) |

| Exigence relative à la fosse | Installation sans fosse |

Comment ça marche

Le système utilise deux ascenseurs parallèles à mouvement alternatif d'une capacité de 5 tonnes.

Les blocs de carbone finis sont transportés sur le chariot élévateur (2200x2200mm) par des lignes de rouleaux fournies par le client.

Des capteurs photoélectriques détectent la charge et déclenchent un motoréducteur SEW de 22 kW qui soulève la cargaison verticalement sur 5 mètres à une vitesse pouvant atteindre 20 m/min.

Après un positionnement précis, les blocs sont déchargés dans l'atelier adjacent, ce qui permet un transport inter-étages rapide et entièrement automatisé.

Les défis

- Fonctionnement en toute sécurité: Exigeait une fiabilité et une stabilité extrêmes pour un fonctionnement entièrement automatisé avec une tolérance zéro pour les temps d'arrêt.

- Un rythme de production rapide: Exigence d'une grande efficacité et d'une réponse rapide pour des cycles quotidiens très élevés.

- Fonctionnement intensif: Les charges de 5 tonnes par cycle représentaient un défi important pour l'intégrité structurelle et le système d'entraînement.

- Contraintes spatiales: La zone d'installation limitée (3380x2900mm) a nécessité une disposition précise, avec un espace d'ajustement dans le sens de la profondeur de la voiture.

- Besoins d'intégration: Il fallait une communication transparente et une intégration de contrôle avec les convoyeurs à rouleaux du client pour une ligne entièrement automatisée.

Solutions

- Fonctionnement en parallèle pour plus d'efficacité et de redondance: Deux ascenseurs installés côte à côte permettent de faire face à la cadence rapide et de fournir une assistance pendant la maintenance, garantissant ainsi un fonctionnement continu sans éclairage.

- Conception robuste: Utilisation de composants en acier aux normes nationales et d'une structure de levage de voitures intégrée pour garantir la solidité et la durabilité à long terme sous des charges de 5 000 kg.

- Composants de base Premium: Un motoréducteur SEW 22KW de grande puissance fournit une alimentation robuste et fiable pour les cycles de démarrage et d'arrêt à haute fréquence.

- Protection de sécurité multicouche:

Prévention des chutes: Dispositif de sécurité mécanique pour empêcher fondamentalement la chute de la voiture.

Protection contre les surcharges: Un capteur intégré bloque le système en cas de surcharge.

Détection des cargaisons: Des capteurs photoélectriques empêchent les marchandises surdimensionnées de provoquer des embouteillages.

Protection électrique: Le système de contrôle comprend l'arrêt d'urgence, la protection contre les pertes de phase, etc. - Intégration flexible: Le système de contrôle PLC fournit des interfaces de communication et une logique complètes pour une intégration facile avec le système de convoyage du client, permettant une coordination intelligente.