9.30.2025 / Lecture en 5 minutes

AGV 6 tonnes guidé par laser | Manutention flexible pour les usines d'assemblage de camions | Système logistique intelligent

Vue d'ensemble

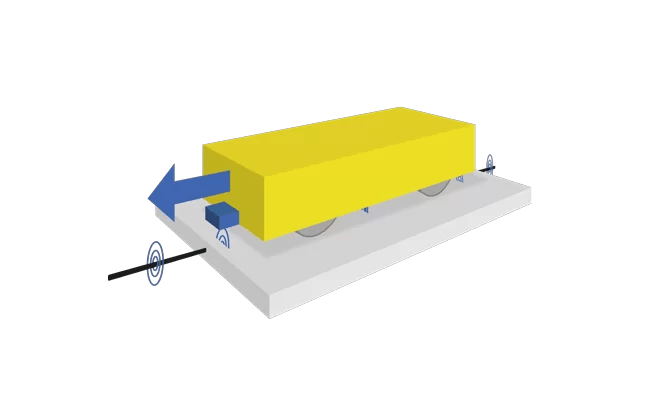

Le présent AGV de 6 tonnes guidé par laser est conçu pour les usines modernes d'assemblage de camions et autres environnements de fabrication d'équipements lourds.

Il résout efficacement le conflit entre manutention de matériaux lourds et lignes de production flexiblesL'utilisation d'un véhicule de transport de marchandises est un élément essentiel de la sécurité : il combine la robustesse nécessaire pour transporter des charges de 6 tonnes avec l'intelligence nécessaire pour naviguer sans problème dans des ateliers complexes et adapter rapidement les itinéraires.

Les coûts élevés et la complexité des voies fixes sont ainsi transformés en une solution logistique intelligente qui offre à la fois une grande efficacité et un bon rapport coût-efficacité.

Paramètres de base

| Paramètres | Spécifications |

|---|---|

| Capacité de charge | 6 tonnes |

| Méthode de navigation | Navigation laser (prend en charge la technologie SLAM sans réflecteur) |

| Flexibilité de la trajectoire | suit des chemins prédéfinis (par exemple, des rubans, des lignes peintes) avec des itinéraires adaptables |

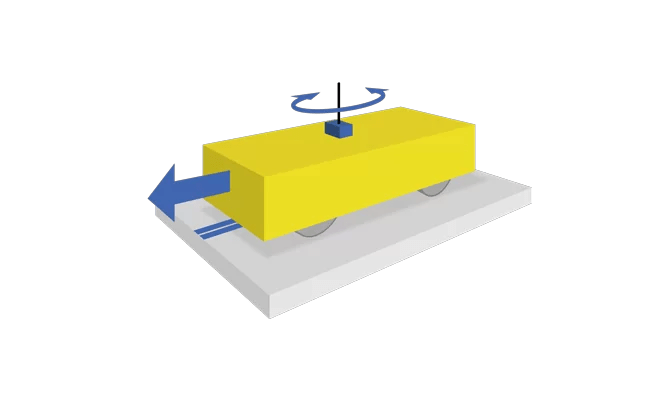

| Performance du mouvement | Fonctionnement à grande vitesse et rotation de 360° sur place |

| Système de communication | Réseau bimode 5G/Wi-Fi pour une réactivité en temps réel |

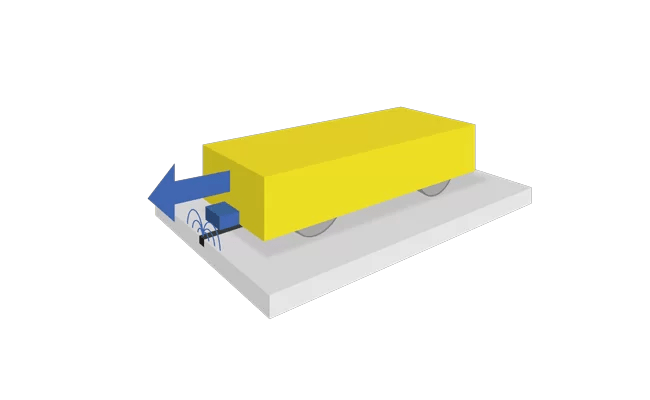

| Protection de la sécurité | Prévention des obstacles par laser à 360°, pare-chocs physiques, boutons d'arrêt d'urgence |

Caractéristiques

- Flexibilité maximale de la mise en page

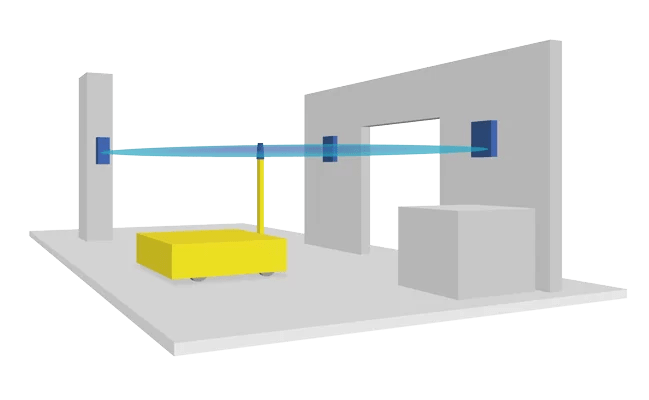

Contrairement aux chariots traditionnels limités par des voies fixes, ce système AGV permet une reconfiguration dynamique des itinéraires. Les chemins peuvent être facilement modifiés ou étendus dans le logiciel en fonction de l'évolution des cycles de production ou des exigences d'optimisation des processus, ce qui offre une adaptabilité inégalée aux changements et aux mises à niveau fréquents des lignes. - Assurance complète de la sécurité

Conçu avec une architecture de sécurité multicouche, le système garantit un fonctionnement fiable. Il comprend un balayage laser sans contact à 360° pour la détection des obstacles, des pare-chocs d'urgence physiques pour un arrêt immédiat en cas de contact, et des boutons d'arrêt manuel, créant ainsi un environnement sécurisé pour la collaboration homme-robot. - Efficacité opérationnelle soutenue

Conçu pour minimiser les temps d'arrêt, l'AGV est compatible avec les systèmes de charge automatique ou de remplacement rapide de la batterie. Intégrées à un système central de gestion de flotte, plusieurs unités exécutent des tâches coordonnées, évitant intelligemment les conflits et optimisant le flux de trafic pour maintenir un fonctionnement continu et à haut débit. - Des avantages économiques indéniables

Bien qu'il nécessite un investissement initial, le système AGV élimine les coûts élevés d'installation et de modification associés aux infrastructures fixes telles que les rails. Il offre un solide retour sur investissement à long terme en remplaçant efficacement plusieurs opérations de chariots élévateurs, en réduisant les coûts de main-d'œuvre et en minimisant les erreurs grâce à une exécution automatisée précise, 24 heures sur 24 et 7 jours sur 7.

Technologie de navigation

Nos AGV lourds se distinguent sur le marché mondial par leurs capacités de manutention de charges avancées combinées à des options de navigation polyvalentes. Chaque projet est conçu en étroite collaboration avec le client, afin que la technologie de guidage sélectionnée - ou une approche hybride - corresponde aux exigences opérationnelles, aux conditions environnementales et aux considérations de coût. Divers systèmes de navigation sont disponibles pour garantir un transport précis, sûr et efficace des charges lourdes et surdimensionnées.

ORIENTATION INDUCTIVE

GUIDAGE INERTIEL

GUIDAGE MAGNÉTIQUE

GUIDAGE OPTIQUE

GUIDANCE LASER

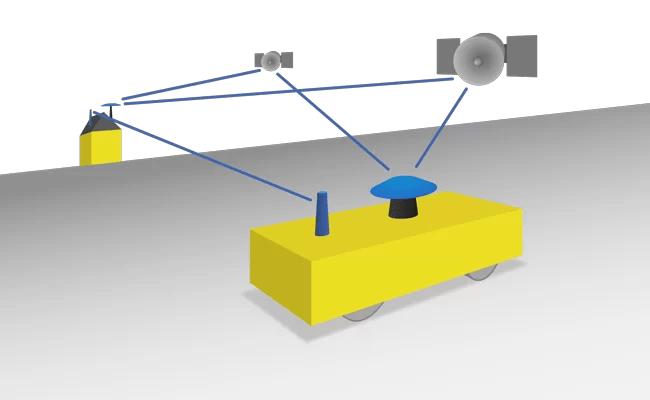

orientations du dGPS

Scénarios d'application et valeur

Dans les usines d'assemblage de camions, cet AGV de 6 tonnes fait office de artère intelligente les étapes d'assemblage. Il livre de manière autonome des composants clés tels que des essieux lourds, des moteurs et des transmissions depuis les entrepôts jusqu'à des positions précises sur la ligne, et participe même à des activités de formation. assemblage du châssis tâches.

Sa valeur réside dans l'intégration de postes de travail isolés dans un système de gestion de l'information. ligne d'assemblage intelligente très flexible et réactive, contribuant directement à l'amélioration de la qualité de vie des citoyens. des délais d'exécution plus courts, des coûts d'exploitation plus faibles et une amélioration de l'efficacité globale des équipements (OEE)-La clé pour passer de la "fabrication traditionnelle" à la "logistique intelligente".

Pour des spécifications détaillées ou des solutions personnalisées, n'hésitez pas à nous contacter.