4.6.2025 / 5-minute read

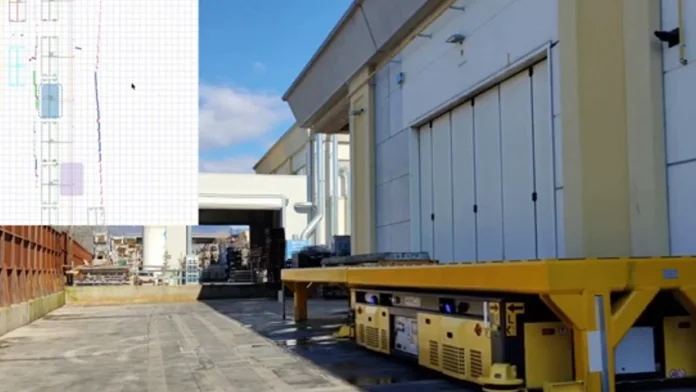

AGV de 40 toneladas para el transporte de chapas de acero - Solución logística automatizada para fábricas

Resumen del proyecto

This 40-ton heavy-duty AGV is customized for the steel industry, solving the challenge of automated transportation for oversized steel plates (27m+ length, 40t+ weight) in high-temperature, high-dust environments.

It integrates laser SLAM navigation, multi-vehicle coordination, and heavy-load stabilization to replace manual/forklift handling, enabling smart factory logistics loops.

Parámetros básicos

| Parámetro | Especificación |

|---|---|

| Capacidad de carga | 40 tons, customizable up to 100 tons |

| Navigation Accuracy | ±10mm (Laser SLAM mode) |

| Método de navegación | Laser SLAM/Magnetic strip/Optical guidance (optional) |

| Drive | Omnidirectional wheels or differential drive (for narrow aisle turning radius ≥ 300mm) |

| Seguridad | 360° laser obstacle avoidance radar + mechanical collision prevention + emergency stop (response time < 0.3 seconds) |

| Medio ambiente | Temperature 0~50°C / Humidity 40%~80% / Dusty environment / IP54 protection |

| Batería | 24 hours continuous operation (supports hydrogen-electric hybrid/wireless charging) |

El desafío

- Eficiencia no tripulada: Elimine la manipulación manual en la logística de grandes volúmenes.

- Integración de AGV: Sincronice los ascensores con los protocolos de navegación y carga de AGV.

- Cumplimiento de las normas de seguridad: Garantiza operaciones a prueba de fallos para cargas pesadas (hasta 2000 kg).

- Resiliencia en entornos difíciles: Funciona en condiciones de interior/exterior de -20°C a 60°C.

Soluciones

- Heavy-Load Stabilization

- Aerospace-grade suspension keeps cargo tilt <1° on uneven ground;

- Multi-motor cooperative drive reduces sway to ≤±5mm during start/stop (“mechanical ballet”).

- Robust Navigation

- Laser SLAM + visual compensation maintains ±15mm accuracy in dust.

- Magnetic tape mode resists steel slag abrasion (service life >10 years).

- Oversized Cargo Handling

- 5G enabled dual-AGV synchronization (lifting/motion error <10mm)13;

- Dynamic path planning reduces turning radius for 27m plates by 40%

Ventajas

✅ Safety Enhancement

- Triple protection (radar + mechanical + E-stop) cuts accident rate by 98%15;

- Explosion-proof version available for flammable environments.

✅ Efficiency Breakthrough

- Unmanned scheduling reduces logistics cycle time by 70%.

- MES/WMS integration enables 99.9% on-time material delivery.

✅ Optimización de costes

- Replaces 10 workers + 3 forklifts with ROI <2 years.

- Hydrogen version reduces energy costs by 52% vs diesel