9.18.2025 / 5-minute read

5-Ton Parallel Reciprocating Lifts in Inner Mongolia Carbon Lights-Out Factory

Overview

This case analysis details the material handling solution for a “lights-out factory” in Inner Mongolia Autonomous Region.

To efficiently transport finished carbon blocks between two workshops with significant level differences at a fast production pace, two parallel reciprocating lifts were deployed.

Since commissioning on August 15, 2025, the system has operated reliably under high-frequency, heavy-duty conditions with zero production-impacting issues.

Basic Parameters

| Parameter | Value |

|---|---|

| Model | SJLT5.0-5.0 |

| Rated Load | 5000 kg |

| Car Size | 2200×2200×1200 mm |

| Platform Size | 2200×2200 mm |

| Required Space | 3200×2600 mm |

| Travel Height | 5000 mm |

| Lifting Speed | 0-30 m/min (Avg. ~20 m/min over 5m due to acceleration) |

| Stations | 2 stops, 2 stations |

| Positioning Accuracy | ±15 mm |

| Drive Unit | 22KW/380V SEW Motor (K107DRN180L4/BE30/V-22KW) |

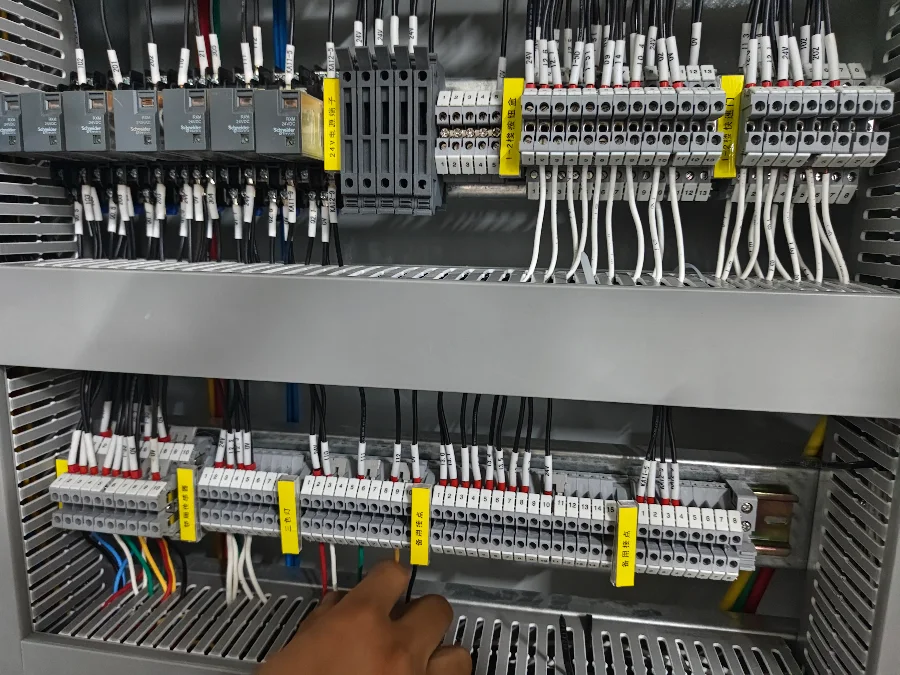

| Control System | PLC (Communication interfaces) |

| Pit Requirement | Pit-free installation |

How It Works

The system employs two parallel 5-ton capacity reciprocating lifts.

Finished carbon blocks are conveyed onto the lift car (2200x2200mm) via customer-supplied roller lines.

Photoelectric sensors detect the load, triggering a 22KW SEW gearmotor to lift the cargo vertically 5 meters at speeds up to 20 m/min.

After precise positioning, the blocks are discharged into the adjacent workshop, enabling fully automated, rapid inter-floor transportation.

The Challenges

- Lights-Out Operation: Demanded extreme reliability and stability for fully automated operation with zero tolerance for downtime.

- Fast Production Pace: Required high efficiency and rapid response for very high daily cycles.

- Heavy-Duty Operation: 5-ton loads per cycle presented a significant challenge to structural integrity and the drive system.

- Space Constraints: Limited installation area (3380x2900mm) required precise layout, with a fit gap in the car depth direction.

- Integration Needs: Required seamless communication and control integration with customer’s roller conveyors for a fully automated line.

Solutions

- Parallel Operation for Efficiency & Redundancy: Two lifts installed side-by-side meet the fast pace and provide backup during maintenance, ensuring continuous lights-out operation.

- Heavy-Duty Design: Utilized national standard steel components and an integrated car-lifting structure to ensure strength and long-term durability under 5000kg loads.

- Premium Core Components: A high-power 22KW SEW gearmotor provides robust and reliable power for high-frequency start-stop cycles.

- Multi-Layer Safety Protection:

Fall Prevention: Mechanical safety gear to fundamentally prevent car falling.

Overload Protection: Integrated sensor locks the system if overloaded.

Cargo Detection: Photoelectric sensors prevent oversized goods from causing jams.

Electrical Protection: Control system includes emergency stop, phase-loss protection, etc. - Flexible Integration: The PLC control system provides comprehensive communication interfaces and logic for easy integration with the customer’s conveyor system, enabling intelligent coordination.