9.17.2025 / Lecture en 5 minutes

Plate-forme de levage mécanique de haute précision pour la maintenance des moteurs d'avion et les essais en soufflerie

Vue d'ensemble

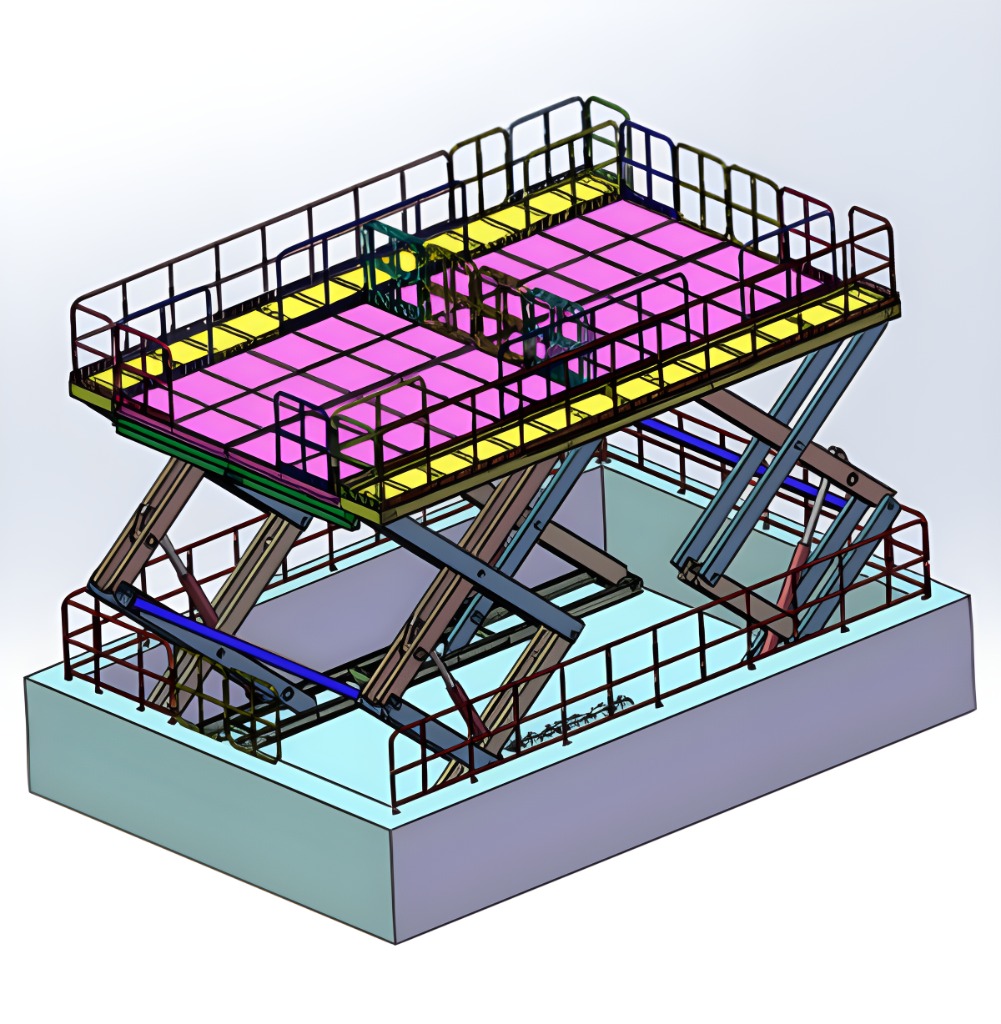

Cette analyse de cas détaille une plate-forme de levage mécanique de haute précision développé sur mesure pour répondre aux exigences spécifiques de l'industrie aérospatiale.

Conçu pour les fabricants de moteurs d'avion et la maintenance des avions, il permet un levage d'une précision millimétrique grâce à des structures mécaniques et des systèmes de contrôle avancés, répondant ainsi aux exigences extrêmes de sécurité et de précision des applications aérospatiales.

Paramètres de base

| Paramètres | Spécifications techniques |

|---|---|

| Précision du positionnement | ±0,5 mm |

| Vitesse de levage | 0,1-5m/min (réglable en continu) |

| Planéité de la plate-forme | ≤1mm/m² |

| Indice de protection | IP65 (résistant à la poussière et à l'eau) |

| Système de contrôle | Servocommande synchrone multi-axes |

| Dispositifs de sécurité | Double verrouillage de sécurité redondant + protection contre les chutes |

| Norme matérielle | Aluminium de qualité aérospatiale/acier inoxydable |

| Plage de température | Plage opérationnelle de -20℃ à +50℃ |

Comment ça marche

L'équipement utilise des systèmes de transmission mécanique de précision et une technologie de servocommande avancée, permettant un mouvement précis et régulier de la plate-forme grâce à un contrôle synchrone multi-axes.

Équipés d'échelles d'accès à la plate-forme, de points de connexion pour les ceintures de sécurité et de mains courantes amovibles, les opérateurs contrôlent le processus de levage par le biais d'une interface conviviale tandis que le système surveille l'état de la charge et de la position en temps réel, garantissant ainsi une sécurité absolue pendant les opérations critiques.

Les défis

Le secteur aérospatial est confronté à des défis uniques en matière de maintenance et de fabrication d'équipements :

- La maintenance des moteurs d'avion et des composants critiques exige une précision de positionnement de l'ordre du millimètre.

- La stabilité et la fiabilité extrêmes des équipements sont essentielles pour les environnements spécialisés tels que les essais en soufflerie.

- Les normes de sécurité strictes nécessitent des mécanismes de sécurité multiples et redondants.

- La diversité des types d'aéronefs et des scénarios opérationnels exige des solutions hautement personnalisées.

- Les équipements doivent fonctionner de manière fiable dans les conditions environnementales uniques des applications aérospatiales.

Solutions

- Contrôle de précision ultime : Un système d'asservissement synchrone multi-axes assure une précision de positionnement de ±0,5 mm.

- Sécurité globale : Les systèmes de sécurité à double redondance, la protection contre les chutes et les points de connexion de sécurité intégrés créent plusieurs niveaux de sécurité.

- Grande capacité de personnalisation : La conception permet diverses configurations, y compris des plates-formes à ciseaux de type U, pour s'adapter à différents modèles d'aéronefs.

- Matériaux de qualité aérospatiale : La construction utilise de l'aluminium aérospatial et de l'acier inoxydable pour une combinaison optimale de légèreté et de durabilité.

- Système de contrôle intelligent : Une interface conviviale rationalise les opérations et améliore l'efficacité du flux de travail.

- Résilience environnementale : Une large gamme de températures de fonctionnement garantit des performances dans divers environnements aérospatiaux.