9.12.2025 / Lecture en 6 minutes

Plate-forme de retournement hydraulique de 50 tonnes pour le noyau d'un transformateur

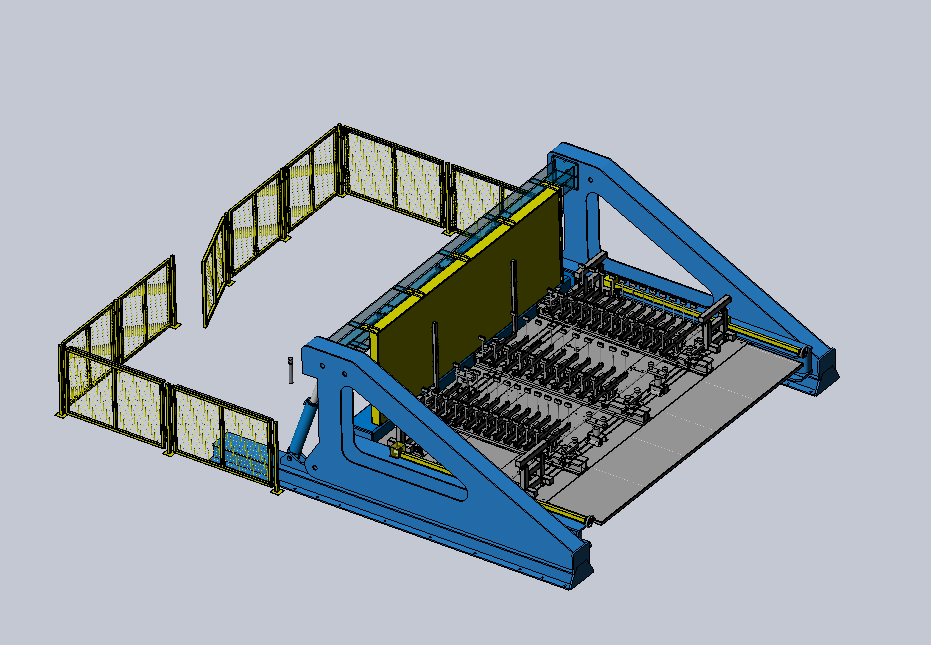

Vue d'ensemble

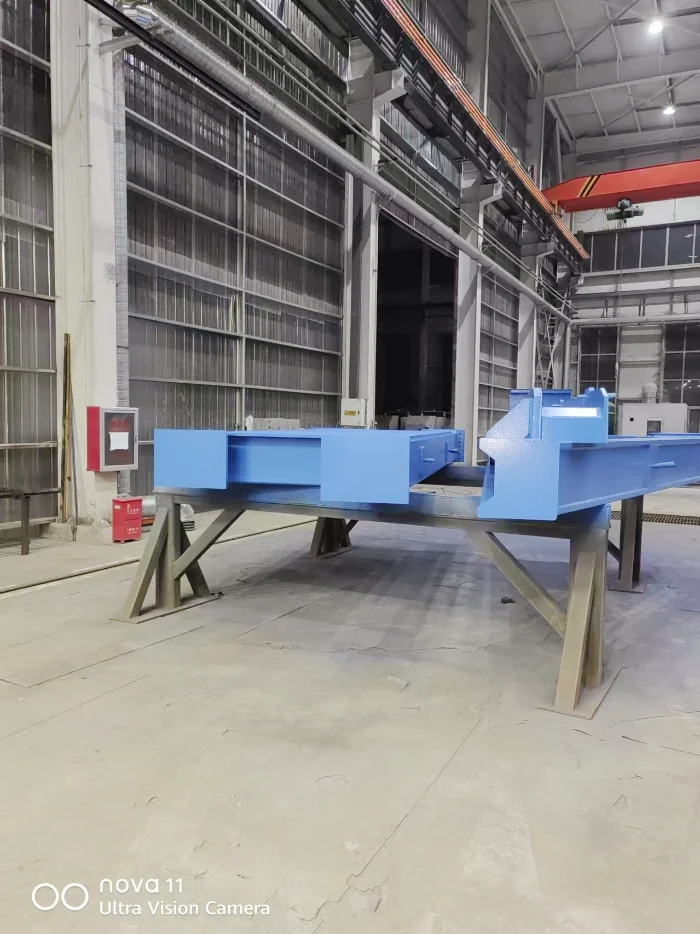

Cette analyse de cas détaille une Plate-forme de retournement hydraulique de 50 tonnes sur mesure pour l'industrie de la fabrication d'équipements électriques.

En tant qu'équipement central des lignes de production de transformateurs, il est spécialement conçu pour l'empilage précis et le retournement en toute sécurité des grands noyaux de transformateurs. Il permet de tourner avec une précision de ±0,5° des noyaux en acier au silicium de 50 tonnes grâce à un entraînement entièrement hydraulique et à des systèmes de contrôle de haute précision.

Paramètres de base

| Paramètres | Valeur/Spécification |

|---|---|

| Charge nominale | 50 tonnes (poids net du noyau) |

| Taille maximale du noyau | 4300×3400mm |

| Taille des tables empilables | 3500×4300×1250mm |

| Angle de rotation | 0-90 degrés |

| Précision de l'angle | ±0.5° |

| Temps de rotation | ≤10 minutes (réglable) |

| Puissance hydraulique | ≤55KW |

| Pression de service | 18-25MPa |

| Précision de la planéité | ≤3mm (sous une charge de 50 tonnes) |

| Durée de vie | >30 ans |

Comment ça marche

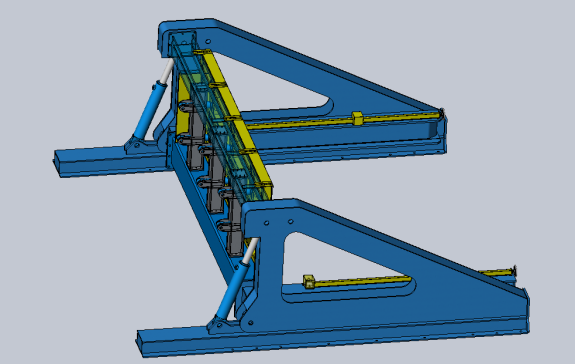

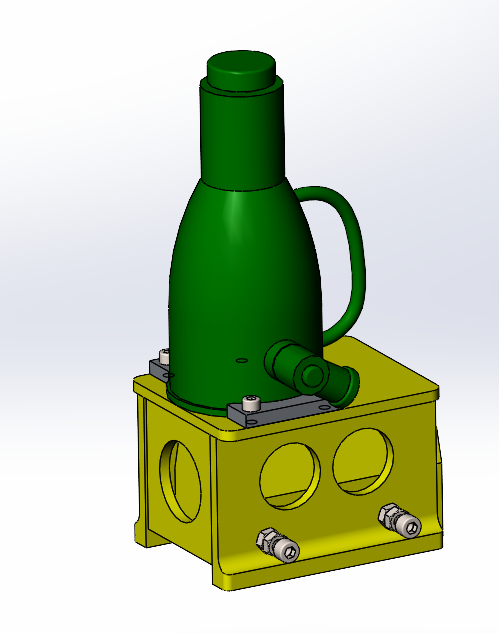

Le système utilise un mécanisme de rotation hydraulique en surface actionné par une unité de puissance de 55KW activant de multiples cylindres hydrauliques synchronisés.

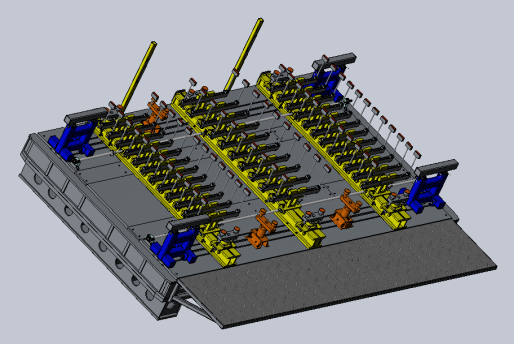

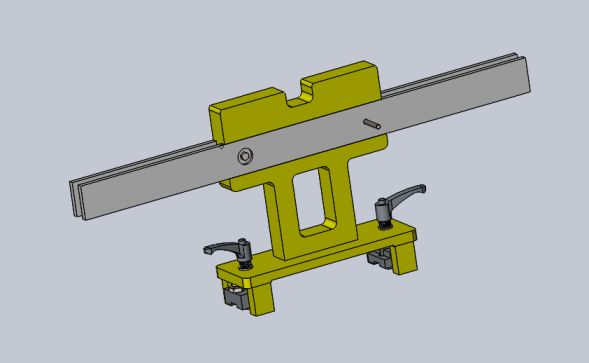

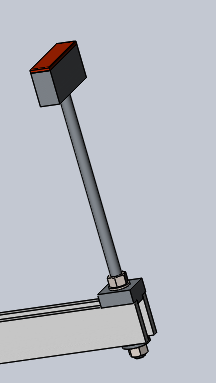

Après un empilage précis sur la table d'empilage de 3500×4300mm, la carotte est rapidement fixée à la plateforme de retournement (≤20 minutes) par des élévateurs à vis sans fin.

La plateforme effectue des virages de 0 à 90° à une vitesse de ≤10min/cycle, avec un contrôle de la pression en temps réel par le système hydraulique.

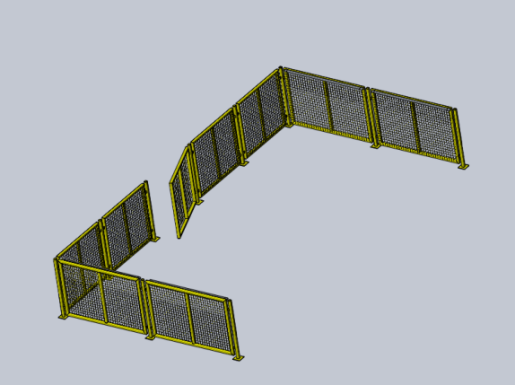

Les vannes et les accumulateurs antidéflagrants garantissent un verrouillage de sécurité en cas d'urgence, tandis que l'automate Siemens S7 permet un contrôle intelligent de trois modes opérationnels par le biais d'une interface à écran tactile.

Les défis

La fabrication des transformateurs est confrontée à de graves problèmes de manipulation des noyaux :

- Risques extrêmes pour la sécurité lors du tournage de noyaux ultra-lourds de 50 tonnes à l'aide de méthodes traditionnelles

- Exigences critiques de planéité (≤3mm) et de précision verticale (±0,5°) pour l'empilage d'acier au silicium.

- Interdiction absolue d'instabilité, de survitesse ou de vibration pendant le virage

- Exigences extrêmes en matière de fiabilité avec une durée de vie de 30 ans

- Nécessité d'un fonctionnement souple dans des modes multiples (production, maintenance, débogage)

Solutions

- Contrôle de précision ultra-lourd: La synchronisation multi-cylindres assure un tournage en douceur de 50 tonnes avec une précision de ±0,5°.

- Double protection de sécurité: Les vannes antidéflagrantes, les accumulateurs et le verrouillage mécanique offrent une triple garantie de sécurité.

- Contrôle intelligent: L'automate Siemens S7 prend en charge trois modes opérationnels pour tous les scénarios

- Fiabilité à long terme: Analyse FEA des composants critiques et durée de vie de 30 ans

- Changement d'outil rapide: Le serrage de la vis sans fin permet une fixation rapide en 20 minutes

- Suivi complet: L'écran tactile affiche en temps réel la pression et les informations sur les défauts pour une maintenance prédictive.