9.28.2025 / 5-Minuten-Lesung

3-Tonnen-Radgreifer Mecanum - wendiger Materialumschlag auf kleinstem Raum

Übersicht

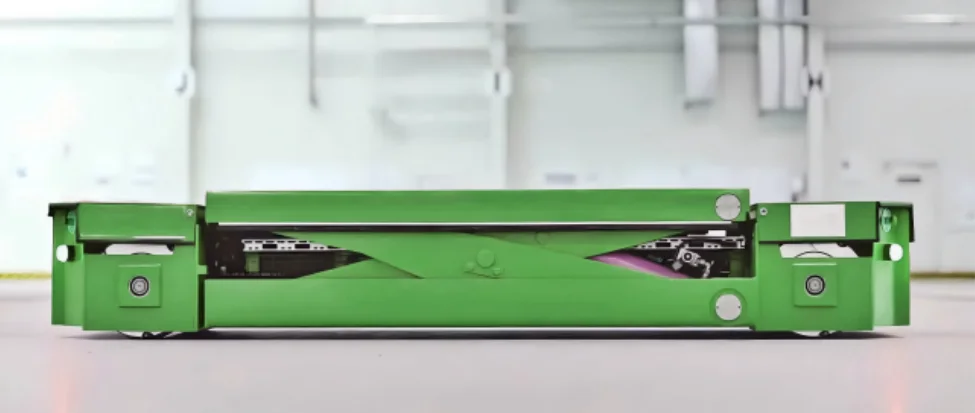

Dieses 3 Tonnen schwere, omnidirektionale Mecanum-Rad-Transferfahrzeug ist eine hochflexible Materialtransportlösung, die für industrielle Umgebungen mit beengten Platzverhältnissen entwickelt wurde.

Sein Hauptvorteil liegt in der Kombination der omnidirektionalen Bewegung der Mecanum-Räder und der präzisen Positionierung der Scherenhubtischplattform.

Er kann Aufgaben, die den horizontalen Transfer, die Drehung und das vertikale Heben von Materialien umfassen, in komplexen Szenarien mit begrenztem Platzangebot und Hindernissen wie Bodenschienen effizient und sicher ausführen.

Grundlegende Parameter

| Spezifischer Indikator | Parameter Wert / Beschreibung |

|---|---|

| Nennlast | 3.000 kg (3 Tonnen) |

| Rad-Typ | Mecanum-Rad |

| Antriebsmethode | Omnidirektionaler Antrieb |

| Plattform Typ | Scherenhebebühne |

| Antriebsmethode | Hydraulischer Aufzug |

| Positionierung | Präzise Höhenkontrolle |

| Bewegungsmodi | Gerade, seitlich, diagonal, Drehung an Ort und Stelle |

| Akku-Typ | Gel-Batterie |

| Methode der Aufladung | Dedizierte Ladestation |

| Primäre Kontrolle | Kabellose Fernsteuerung |

| Notsteuerung | Not-Aus-Schaltkasten |

| Warneinrichtungen | Licht- und Tonalarm |

| Physische Sicherheit | Druckempfindliche Sicherheitspuffer |

Wie es funktioniert

- Bewegung: Der Bediener sendet seine Befehle über eine drahtlose Fernbedienung. Das Steuersystem treibt die vier Mecanum-Räder zu einer koordinierten Drehung an und erzeugt dabei kombinierte Kräfte in jede Richtung. So kann das Fahrzeug vorwärts, rückwärts, links, rechts und diagonal fahren und sich auf der Stelle drehen, um Hindernisse zu umfahren und an engen Stellen anzudocken.

- Heben: Wenn eine Höhenverstellung erforderlich ist, wird die hydraulische Hebebühne aktiviert und fährt den Scherenmechanismus sanft aus oder ein, um die Plattform auf die exakte Höhe zu heben oder zu senken, die für das Be- und Entladen oder die Verbindung mit Geräten erforderlich ist.

- Überwachung der Sicherheit: Während des gesamten Einsatzes wird das Personal durch Licht- und Tonalarm gewarnt. Die Sicherheitspuffer stoppen das Fahrzeug sofort, wenn es mit Hindernissen oder Personen in Berührung kommt, und gewährleisten so die Betriebssicherheit.

Die Herausforderungen

- Platzbeschränkungen: Herkömmliche Gabelstapler können in engen Gängen nicht wenden, was zu einer geringen logistischen Effizienz führt.

- Präzises Andocken: Dichte Produktionslinien erfordern Geräte, die seitliche Anpassungen im Millimeterbereich ermöglichen.

- Bodenhindernisse: Das Vorhandensein von Bodenspuren, Kanälen oder Rillen kann die reibungslose Durchfahrt von herkömmlichen Fahrzeugen behindern.

- Sicherheit von Mensch und Maschine: Die Gewährleistung absoluter Sicherheit für das Personal in gemeinsamen Mensch-Roboter-Arbeitsumgebungen ist von entscheidender Bedeutung.

Lösungen

- Omnidirektionale Plattform: Die Mecanum-Radtechnologie macht den traditionellen Wenderadius überflüssig, so dass das Fahrzeug frei in Gängen fahren kann, die nur wenig breiter sind als es selbst, was die Raumnutzung erheblich verbessert.

- Integrierte Hebefunktion: Die Kombination aus Scherenhebebühne und omnidirektionalem Fahrgestell ermöglicht eine präzise 3D-Positionierung (X-, Y-, Z-Achse) von Materialien, um verschiedene Anforderungen an die Arbeitshöhe zu erfüllen.

- Anpassung an komplexe Umgebungen: Das Design der Mecanum-Räder mit durchgehenden Rollen ermöglicht es dem Fahrzeug, Bodenschienen und kleine Rillen reibungslos zu überqueren, wodurch Kontinuität und Stabilität des Betriebs gewährleistet werden.

- Mehrstufiger Sicherheitsschutz: Der duale Steuerungsmodus ("Wireless Remote + Emergency Box") in Verbindung mit audiovisuellen Alarmen und kontaktbasierten Notausschaltern (Bumpern) schafft ein umfassendes Sicherheitssystem, das für die Zusammenarbeit zwischen Mensch und Roboter geeignet ist.