8.26.2025 / 5-Minuten-Lesung

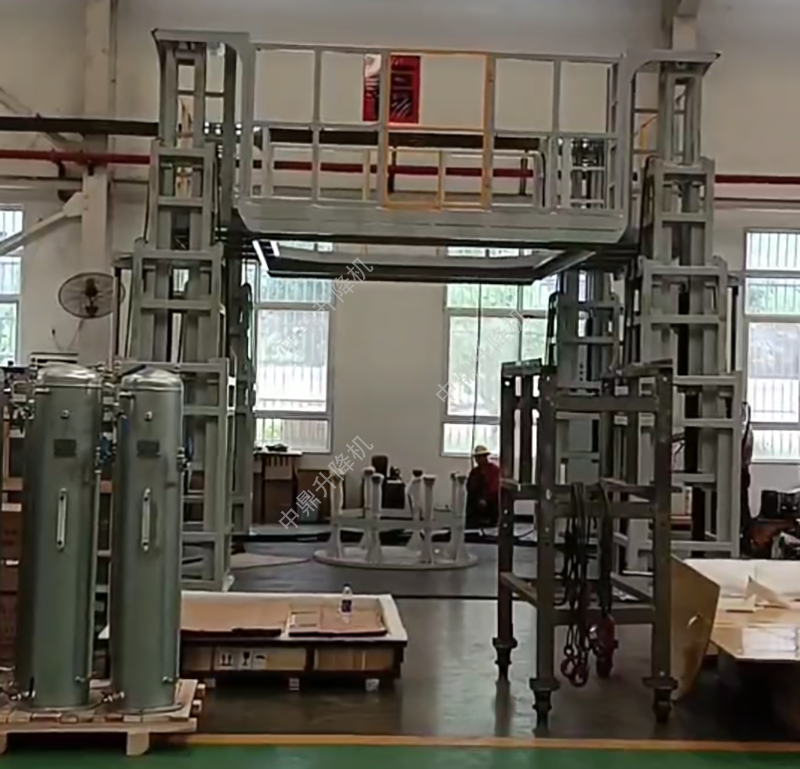

Mehrstufige Teleskop-Hydraulik-Hebebühne für die Montage von Wasserstoff-Elektrolyseuren - Wartungsbühne für Schwerlastanlagen

Überblick über das Projekt

Diese Fallstudie analysiert unser Mehrstufige Teleskop-Hydraulik-Hebebühne die für schwere und hochpräzise Montageanwendungen entwickelt wurden.

Diese Geräte sind für ihre außergewöhnliche Stabilität, ihre hohe Tragfähigkeit und ihren flexiblen Arbeitsbereich bekannt und haben sich in der modernen industriellen Fertigung, insbesondere in der schnell wachsenden grüner Wasserstoff Sektor für die Montage von Elektrolyseuren.

Sein Kernwert liegt in der Erfüllung der strengen Anforderungen an reibungslose, sichere und kollaborative Hebevorgänge bei der Montage und Wartung von großen, schweren Geräten.

Wie es funktioniert

- Energie-Aktivierung:

Der Prozess beginnt mit der Aktivierung des Elektromotors durch die Hydraulikaggregat (Pumpstation)das Hochdruck-Hydrauliköl erzeugt. - Ölverteilung:

Dieses Hochdrucköl wird dann über das Steuersystem präzise an die vier unabhängigen Hubzylinder. - Synchrones Heben:

Jeder Zylinder treibt den entsprechenden Satz von mehrstufige Teleskopbeine sich gleichzeitig und gleichmäßig auszudehnen. - Stufenweise Erweiterung:

A Traktionskette Mechanismus sorgt dafür, dass die verschiedenen Stufen jedes Teleskopbeins gleichmäßig und nacheinander ausfahren, so dass ein Verklemmen oder Blockieren verhindert wird. - Bewegung der Plattform:

Die synchronisierte Streckung der vier Beinsätze hebt den gesamten Ladefläche gleichmäßig nach oben. Die Umkehrung dieses Vorgangs (Einfahren der Beine) senkt die Plattform. - Präzise Positionierung:

Die Plattform kann in jeder gewünschten Position innerhalb des gesamten Verfahrbereichs angehalten und sicher gehalten werden. - Sicherheitsverriegelung:

Sobald das Hydrauliksystem in Position ist, wird die Druckerhaltungs- und Selbstverriegelungsfunktion ein und halten die Plattform und ihre Ladung auch ohne Strom sicher an Ort und Stelle.

Grundlegende Parameter

| Parameter | Wertebereich / Beschreibung | Hinweis |

|---|---|---|

| Tragfähigkeit | 1 - 100 Tonnen | Anpassbar |

| Plattform Größe | Kundenspezifisch, z. B. 3m x 3m - 6m x 8m | Maßgeschneidert auf die Anforderungen |

| Hubhöhe | Benutzerdefiniert, bis zu 18 Meter oder höher | Erreicht durch mehrstufiges Design |

| Min. Arbeitshöhe | ~500 - 800 mm | |

| Stromversorgung | 380V/50Hz 3-Phasen-Wechselstrom | |

| Kontrolle | Kabellose Fernbedienung + Platform Control Box | Duale Kontrollpunkte |

| Gewicht | Je nach Konfiguration |

Die Herausforderung

- Sanfte und präzise Steuerung von schweren Lasten: Kernkomponenten wie Elektrolyseure sind hochwertig und extrem schwer. Sie erfordern einen Hebeprozess, der außergewöhnlich sanft, stoß- und vibrationsfrei ist und eine millimetergenaue Positionierung ermöglicht.

- Langfristiges, sicheres Parken: Aufwendige Montage- oder Wartungsarbeiten sind zeitraubend. Die Plattform muss unter Last über lange Zeiträume absolut statisch und sicher verriegelt bleiben, um ein unbeabsichtigtes Absinken zu verhindern.

- Anforderung an den kollaborativen Arbeitsbereich: Bei der Montage von Großgeräten müssen mehrere Techniker gleichzeitig um und unter der Plattform arbeiten, was einen großen, ungehinderten Platz in der Mitte erfordert.

- Hohe Anpassungsfähigkeit: Die Ausrüstung muss sich an die verschiedenen Bedingungen in der Fabrik anpassen und eine stabile Grundlage bieten.

Lösungen

Sanfte und präzise Steuerung von schweren Lasten: Kernkomponenten wie Elektrolyseure sind hochwertig und extrem schwer. Sie erfordern einen Hebeprozess, der außergewöhnlich sanft, stoß- und vibrationsfrei ist und eine millimetergenaue Positionierung ermöglicht.

Langfristiges, sicheres Parken: Aufwendige Montage- oder Wartungsarbeiten sind zeitraubend. Die Plattform muss unter Last über lange Zeiträume absolut statisch und sicher verriegelt bleiben, um ein unbeabsichtigtes Absinken zu verhindern.

Anforderung an den kollaborativen Arbeitsbereich: Bei der Montage von Großgeräten müssen mehrere Techniker gleichzeitig um und unter der Plattform arbeiten, was einen großen, ungehinderten Platz in der Mitte erfordert.

Hohe Anpassungsfähigkeit: Die Ausrüstung muss sich an die verschiedenen Bedingungen in der Fabrik anpassen und eine stabile Grundlage bieten.

Galerie