11.3.2025 / 5-minute read

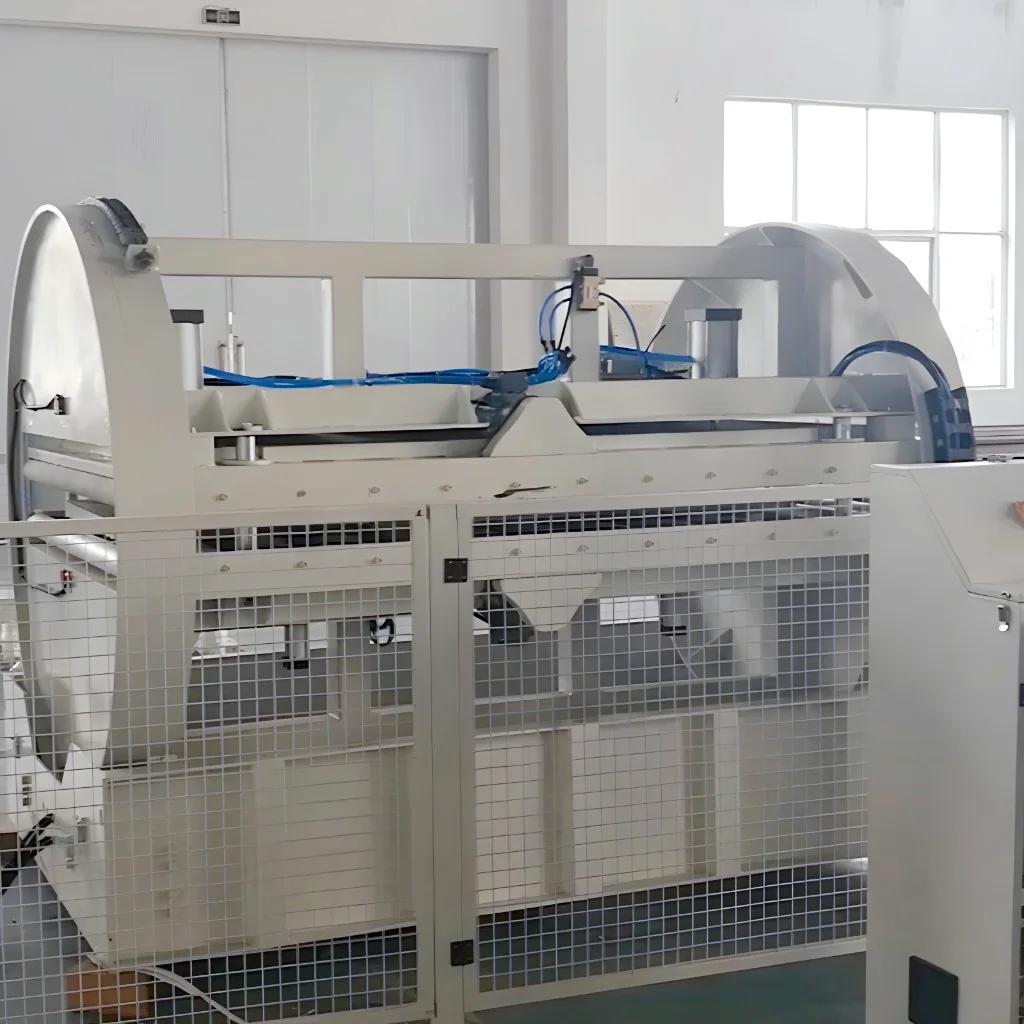

Automated Steel Plate Turnover Machine | 180° Flip Solution for Stamping Lines

Overview

This case study explores how an Automated 180° Plate Turnover Machine (also known as a Steel Plate Turner) resolved critical bottlenecks in a high-volume stamping line.

By automating the flipping of large, delicate sheet stacks, the solution dramatically reduced surface scratches, slashed labor costs, and increased overall line throughput by over 20%, delivering a full ROI in under 18 months.

Basic Parameters

| Model | B21-FZ03T | B21-FZ05T | B21-FZ10T | B21-FZ15T |

|---|---|---|---|---|

| Capacity | 3 Tons | 5 Tons | 10 Tons | 15 Tons |

| Motor Power | 1.5 kW | 2.2 kW | 2.2 kW | 3.0 kW |

| Turning Speed | 30s ±10% | 30s ±10% | 40s ±10% | 40s ±10% |

| Table Size | 800–2500mm (Customized according to workpiece size) | 800–2500mm (Customized according to workpiece size) | 800–2500mm (Customized according to workpiece size) | 800–2500mm (Customized according to workpiece size) |

| Drive Method | Mechanical drive or hydraulic drive | Mechanical drive or hydraulic drive | Mechanical drive or hydraulic drive | Mechanical drive or hydraulic drive |

| Table Shape | ① A-flat/B-flat surface ② A-flat/B “V” saddle surface ③ Customized surface | ① A-flat/B-flat surface ② A-flat/B “V” saddle surface ③ Customized surface | Customized surface | Customized surface |

| Operation Mode | ① Pendant control ② Wireless remote control ③ Control cabinet buttons | ① Pendant control ② Wireless remote control ③ Control cabinet buttons | Control cabinet buttons | Control cabinet buttons |

| Self Weight | 1.5T | 2.0T | 2.5T | 3.0T |

| Turning Angle | 90° / 180° / 360° | 90° / 180° / 360° | 90° / 180° / 360° | 90° / 180° / 360° |

| Power Supply | 380V three-phase four-wire 50Hz | 380V three-phase four-wire 50Hz | 380V three-phase four-wire 50Hz | 380V three-phase four-wire 50Hz |

Challenges

- Product Damage: Manual handling with cranes and slings inevitably caused surface scratches and scuffs, leading to high rejection rates and costly rework.

- Labor-Intensive & Unsafe: The process required multiple operators for a physically demanding and hazardous task, posing a significant safety risk.

- Production Bottleneck: The slow, inconsistent flipping cycle created a major pacing issue, limiting the output of the entire automated stamping cell.

- Incompatible with Automation: The manual station could not integrate with the plant’s MES, creating a data black hole.

Our Solution

- Automatic Loading & Positioning:

- The upstream conveyor transfers the sheet stack into the turnover machine’s open infeed section.

- Secure Hydraulic Clamping Sequence:

- Upper/Lower Cylinders actuate to drive clamping plates, securely pressing the stack from the top and bottom.

- A subsequent rear cylinder drives a backstop plate forward, completing a three-point fixation process that firmly holds the stack without distortion.

- Precision 180° Rotation:

- An AC motor coupled with a high-torque reduction gearbox drives the entire clamping assembly through a smooth, controlled 180° rotation.

- The robust mechanical design ensures perfect alignment and eliminates any risk of sheet slippage.

- Automatic Unloading:

- After the flip, the clamping cylinders retract, releasing the stack.

- The now-flipped stack is automatically transferred onto the downstream conveyor, ready for the next operation.

- Seamless PLC Integration:

- The machine’s PLC synchronizes perfectly with the main production line controller, ensuring a continuous, uninterrupted material flow and providing real-time status updates to the MES.