8.22.2025 / 4-minute read

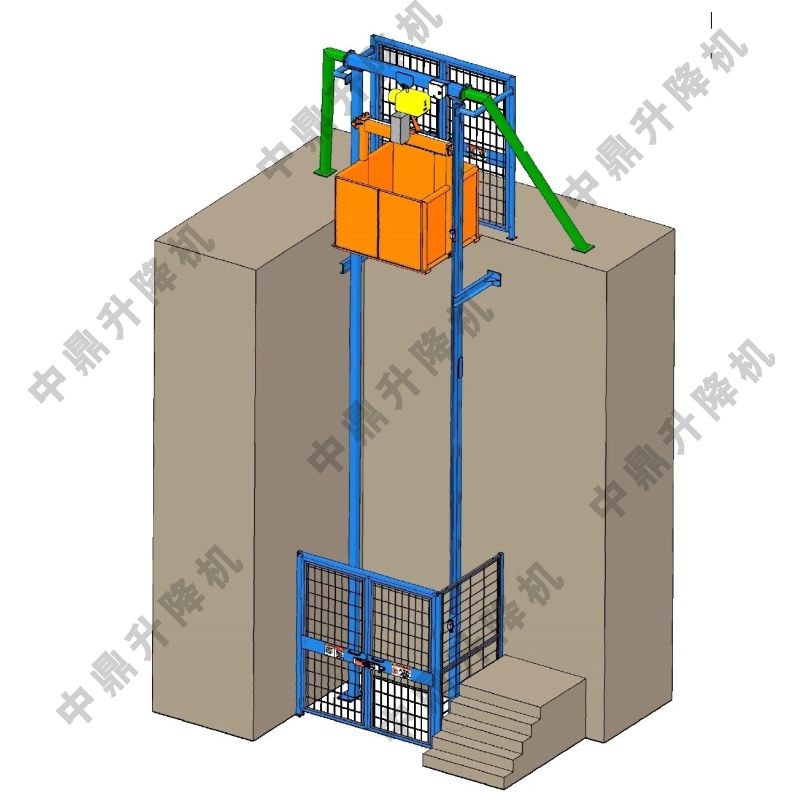

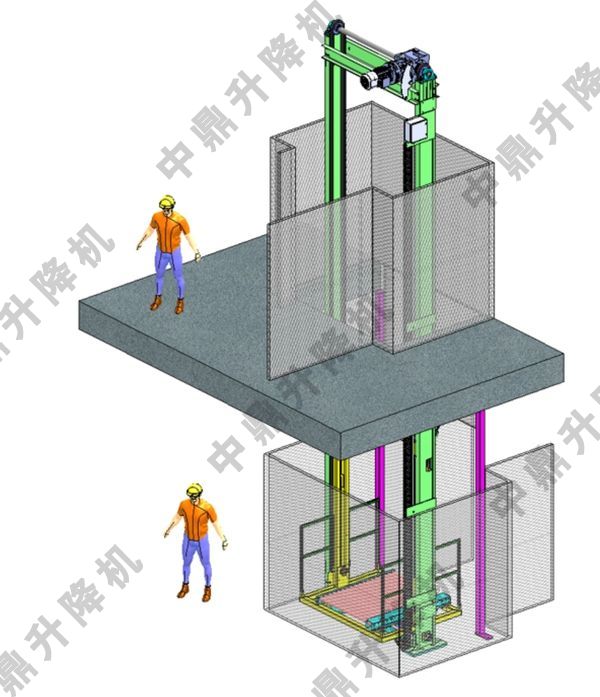

Straddle-Type Reciprocating Lift – High-Capacity & Flexible Vertical Transport Solution

Overview

The straddle-type reciprocating lift is an efficient material handling solution designed with a unique structure where the cargo compartment is positioned between two guide columns.

This configuration evenly distributes the load weight along both columns, providing enhanced stability and higher load-bearing capacity compared to cantilever-style lifts.

It supports both C-type (same-side loading/unloading) and Z-type (opposite-side loading/unloading) operations, making it highly adaptable to various logistics workflows.

With its minimalist safety guard design and ability to handle diverse cargo sizes and weights, this lift is ideal for applications requiring high efficiency, robust performance, and flexibility in vertical transportation across multiple levels.

Basic Parameters

| Parameter Category | Parameter Item | Parameter Range / Typical Value |

|---|---|---|

| Load Dimensions | Length (L) | 800 ~ 2900 mm |

| Width (W) | 800 ~ 2900 mm | |

| Height (H) | 150 ~ 2400 mm | |

| Load Capacity | Load Weight | 15 ~ 3000 kg/pallet |

| Speed & Efficiency | Lifting Speed (S) | Chain Drive: 35 ~ 90 m/min |

| Rack and Pinion Drive: 35 ~ 65 m/min | ||

| Synchronous Belt Drive: 90 ~ 150 m/min | ||

| Handling Efficiency | ≤ 150 pallets/hour | |

| Transfer Cycle Time | > 15 seconds/item | |

| Travel & Height | Max. Lifting Height | ≤ 20 m |

| Machine Dimensions | Machine Width (VW) | VW = Load Width (W) + 1180 mm |

| Machine Length (VL) | VL = Load Length (L) + 600 mm | |

| Other Parameters | Inlet/Outlet Direction | Z-type (opposite sides), C-type (same side), E-type, etc. |

| Transfer Height (HS1) | ≥ 650 mm | |

| Ambient Temperature | -10℃ ~ 40℃ (Indoor, frost-free) | |

| Drive Method | Chain, Rack and Pinion, Synchronous Belt |

The Challenge

- Need for High Load Capacity: Traditional cantilever lifts struggle with heavy loads and uneven weight distribution.

- Space and Workflow Adaptability: Logistics operations often require flexible loading/unloading methods to optimize efficiency.

- Handling Diverse Cargo: Facilities dealing with varying cargo sizes and weights need a versatile lifting solution.

- Cost Efficiency: Balancing safety and performance while minimizing structural complexity and maintenance costs.

Solutions

Enhanced Structural Design:

The straddle-type configuration evenly distributes weight along two guide columns, enabling higher load capacity and greater resistance to tipping forces.

Flexible Loading/Unloading Options:

Supports both C-type and Z-type operations, allowing seamless integration into diverse logistics workflows.

Adaptability to Various Cargo Types:

The large platform and robust design enable efficient handling of different cargo sizes and weights without compromising performance.

Cost-Effective Safety:

A minimalist guard design reduces material and manufacturing costs while maintaining compliance with safety standards.

Efficient Vertical Transportation:

Enables fast and secure movement of goods across multiple floors, improving overall operational efficiency in warehouses and industrial settings.

Gallery