9.9.2025 / 5-минутное чтение

8-тонный токарный станок для тяжелых компонентов - прецизионное токарное оборудование для производства зубчатых колес

Обзор

В данном примере рассматривается 8-тонный тяжелый токарный станок.

Специально разработан для прецизионной обработки тяжелых деталей, таких как электрические колесаОна решает задачу многоугольного позиционирования крупных деталей зубчатого типа в процессе обработки с помощью инновационная платформа с U-образными пазами и мультиинструментальная система.

Основные параметры

| Параметр | Значение/Описание |

|---|---|

| Номинальная нагрузка | 8000 кг |

| Размер платформы | 2000*2000+2000*2000mm |

| Угол поворота | 90 градусов |

| Скорость поворота | <50 секунд/цикл |

| Мощность привода | Редукторный двигатель 3KW марки SEW |

| Материал основной рамы | Стальной профиль J200*100*6 |

| Толщина платформы | 8 мм |

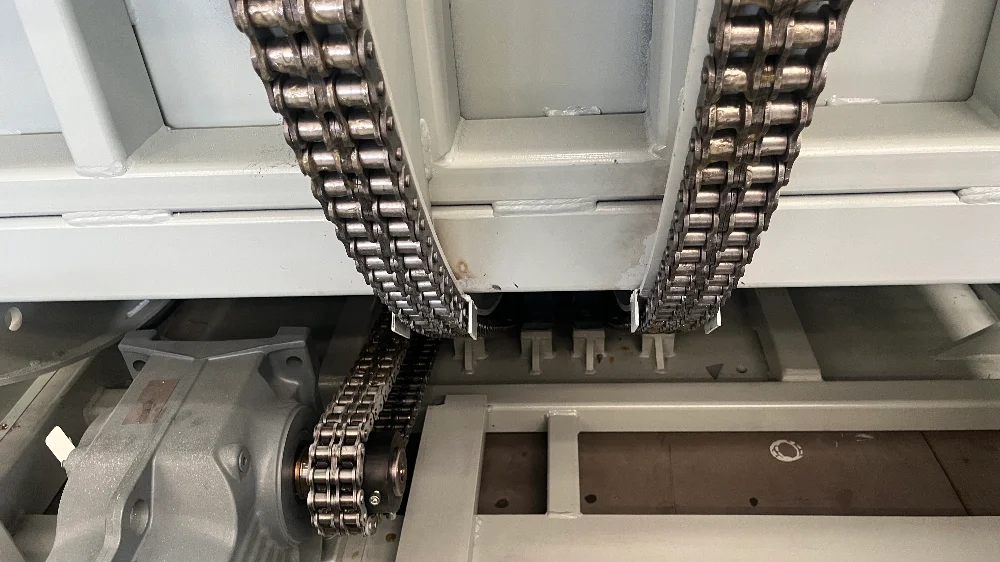

| Спецификация цепи | 20A-2 |

| Система управления | Электрические компоненты Schneider |

| Цвет оборудования | RAL7035 |

Как это работает

Для точного поворота платформы на 90 градусов в оборудовании используется цепная передача с мотор-редуктором.

Одна платформа оснащена U-образными пазами и Т-образными пазами, а другая - съемными V-образными пазами и натяжными устройствами для обработки заготовок различных спецификаций.

Операторы управляют системой с помощью внешнего портативного кнопочного блока с функцией jog control.

Проблемы

- Крупные компоненты, такие как электрические колеса, представляют опасность для безопасности при ручном повороте

- Обычное токарное оборудование не может удовлетворить требованиям к точности позиционирования

- Различные спецификации требуют различных методов зажима и крепления

- Производственные процессы требуют многократных поворотов и точного позиционирования

- Трудности с мобильностью и настройкой оборудования влияют на гибкость планировки мастерской

Решения

- Точное позиционирование: Многофункциональная конструкция U-паз + T-паз + V-паз обеспечивает стабильность заготовки

- Безопасная эксплуатация: Приводная система SEW с электрическим управлением Schneider обеспечивает эксплуатационную надежность

- Эффективное вращение: поворот на 90 градусов за 50 секунд повышает эффективность производства

- Мобильный дизайн: Пазы для вилочного погрузчика в основании облегчают перестановку оборудования

- Универсальная адаптация: Съемные V-образные канавки и натяжные ролики позволяют обрабатывать различные заготовки

- Обеспечение безопасности: 8-тонный стопорный ремень с функцией самоблокировки обеспечивает безопасность эксплуатации