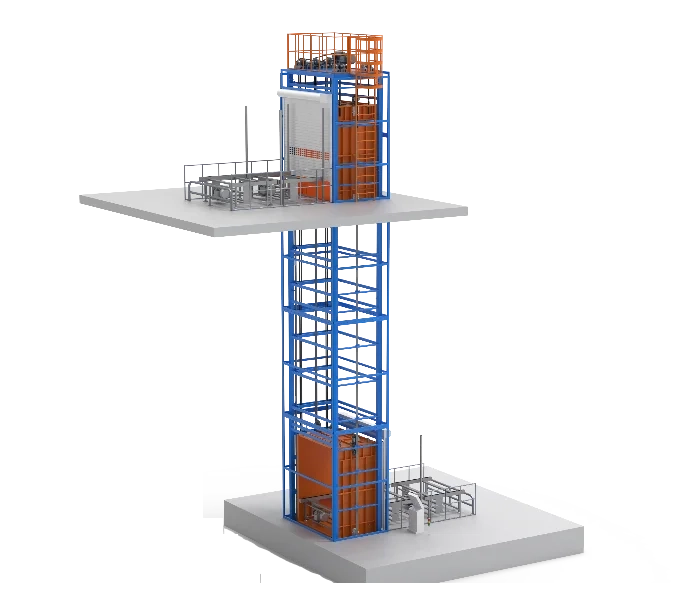

Transportador recíproco vertical

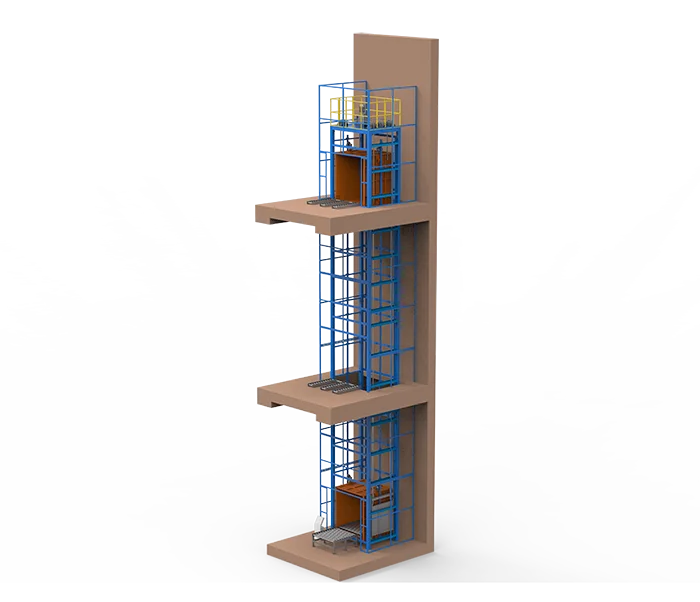

Otimize o transporte vertical, aumente a eficiência operacional e garanta o manuseio seguro da carga com nossos avançados VRCs (Vertical Reciprocating Conveyors, transportadores verticais alternativos) projetados para a movimentação contínua de mercadorias paletizadas em vários níveis.

Para saber mais fale com nossa equipe

O design minimalista do guarda-corpo reduz os custos: Usa menos gabinetes para garantir a segurança e melhorar a relação custo-benefício.

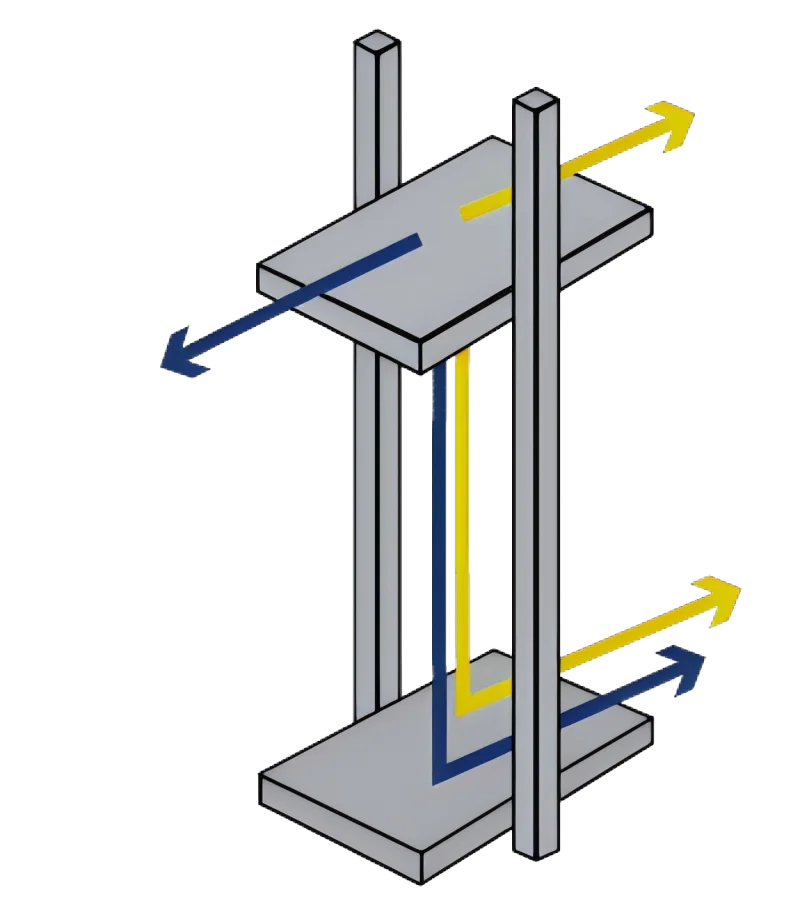

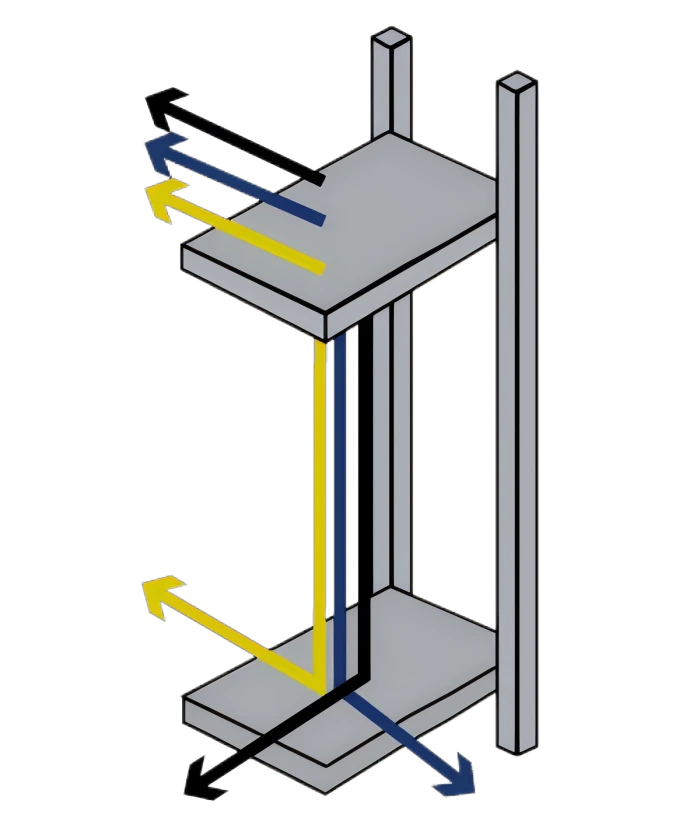

Opções de carga e descarga: Suporta descarregamento tipo C (mesmo lado) e descarregamento tipo Z (lado oposto) para se adequar a diferentes processos logísticos.

Versátil para vários tamanhos de carga: Projetado para lidar facilmente com diferentes pesos e dimensões de materiais.

Transporte vertical eficiente: Movimenta mercadorias de forma rápida e segura entre os níveis, aumentando a eficiência operacional.

Deseja saber mais? Nosso útil

A equipe está aqui para ajudar.

Solicite uma cotação

Veja nossa linha de Transportadores recíprocos verticais

Tamanho da plataforma: Personalização

Altura do elevador: até 15 m

Velocidade de elevação: ≥40m/min

Tamanho da plataforma: Personalização

Altura do elevador: até 30 m

Velocidade de elevação: 0,1-0,5 m/s

Tamanho da plataforma: Personalização

Altura do elevador: até 50 m

Velocidade de elevação: 0,2-1,0 m/s

Tamanho da plataforma: 2,5-6 m (largura) × 1,8-4 m (profundidade)

Altura do elevador: até 20 m

Velocidade de elevação: ≥30m/min

Veja nossos casos de VRC

Perguntas frequentes sobre o transportador vertical alternativo

A instalação de um transportador alternativo vertical (VRC) pode exigir modificações estruturais, dependendo de seu projeto, capacidade e ambiente de instalação. Veja abaixo uma análise profissional:

Requisitos estruturais para a instalação do VRC

Reforço do piso

- VRCs para serviços leves (<1.000 lbs/450 kg): Podem precisar apenas de reforço localizado do piso (por exemplo, placas de aço ou travessas).

- VRCs para serviços pesados (>2.000 lbs/900 kg): Exigem bases de concreto ou suportes de viga I de aço para distribuir as cargas com segurança (de acordo com a ANSI/ASME B20.1).

Considerações sobre o eixo vertical

- Sistemas guiados: Necessitam de alinhamento estrutural com colunas do edifício ou estruturas de aço dedicadas para trilhos de guia.

- Altura livre: Deve-se manter uma folga mínima acima da cabeça (normalmente de 12 a 18 polegadas acima do caminho de deslocamento).

| Tipo de VRC | Faixa de capacidade padrão | Capacidade máxima* |

|---|---|---|

| Industrial padrão VRC | 1.000 - 20.000 lbs (450 - 9.000 kg) |

50.000 lbs (22.680 kg) |

| VRC hidráulico | 5.000 - 30.000 lbs (2.270 - 13.600 kg) |

100.000 lbs (45.360 kg) |

Os dados acima representam os preços médios de mercado para VRCs e não refletem os preços da Gradin. Para obter preços específicos, consulte nossa equipe de profissionais.

| Tipo de VRC | Faixa de capacidade | Faixa de preço base* | Principais fatores de custo |

|---|---|---|---|

| VRC elétrico padrão | 1.000-5.000 lbs (450-2.270 kg) |

$15,000 – $35,000 | Tamanho da plataforma, altura do elevador, sistema de controle |

| VRC industrial hidráulico | 5.000-20.000 lbs (2.270-9.070 kg) |

$40,000 – $85,000 | Capacidade da mangueira/bomba, reforços estruturais |

| VRC personalizado para serviços pesados | 20.000-100.000+ lbs (9.070-45.360+ kg) |

$90,000 – $250,000+ | Guias especializadas, à prova de explosão, automação |

Componentes críticos de custo:

- ✓ Sistema de acionamento: Elétrica (15% mais barata) vs Hidráulica (ciclos de trabalho mais altos)

- ✓ Altura do elevador: Adiciona $800-$1.500 por andar adicional (≥10 pés/3m)

- ✓ Controles: Pendente básico ($1.5k) vs. automação PLC ($8k-$15k)

- ✓ Recursos de segurança: Portões em conformidade com ANSI (+$3k), cortinas de luz (+$4.5k)