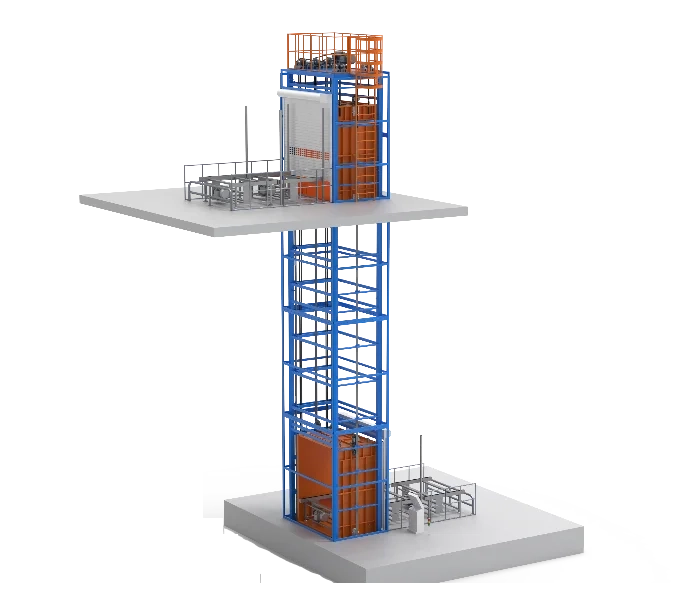

수직 왕복 컨베이어

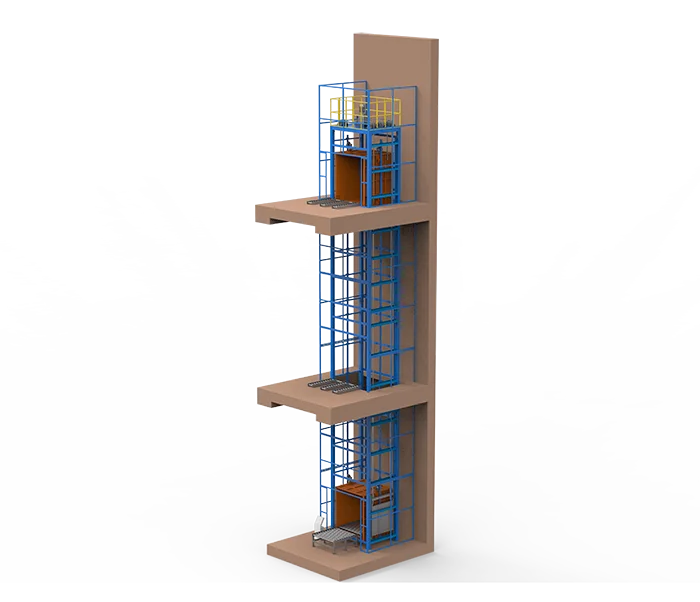

여러 층에 걸쳐 팔레트화된 상품을 원활하게 이동하도록 설계된 첨단 수직 왕복 컨베이어(VRC)로 수직 운송을 최적화하고 운영 효율성을 높이며 안전한 화물 취급을 보장합니다.

자세히 알아보기 팀에 문의

미니멀한 가드레일 디자인으로 비용 절감: 더 적은 수의 인클로저를 사용하여 안전을 보장하고 비용 효율성을 개선합니다.

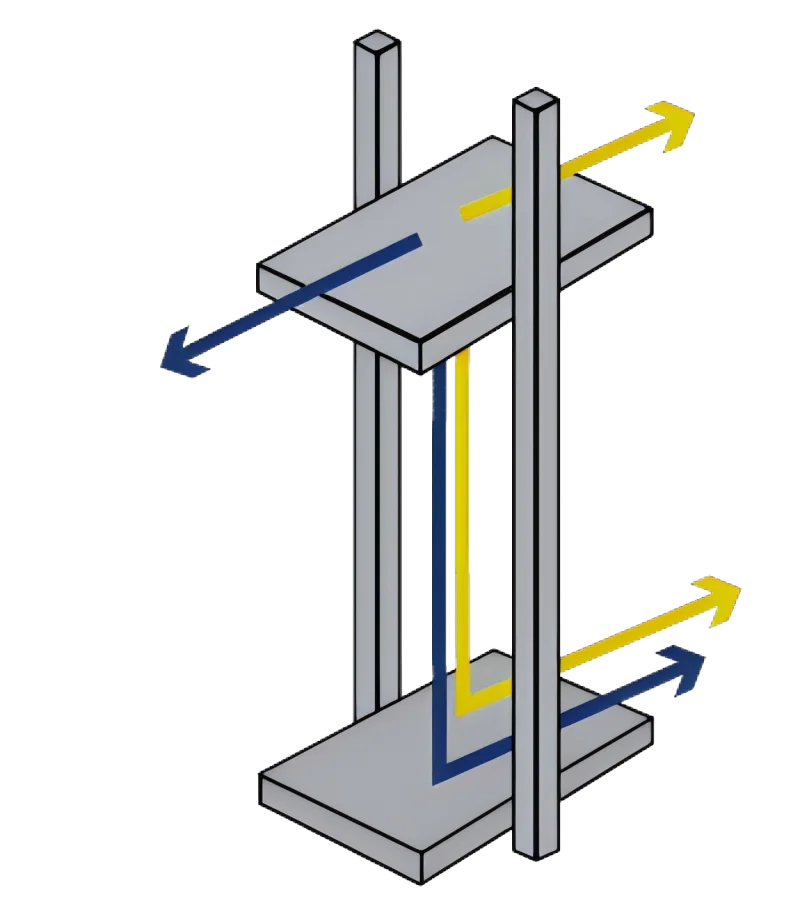

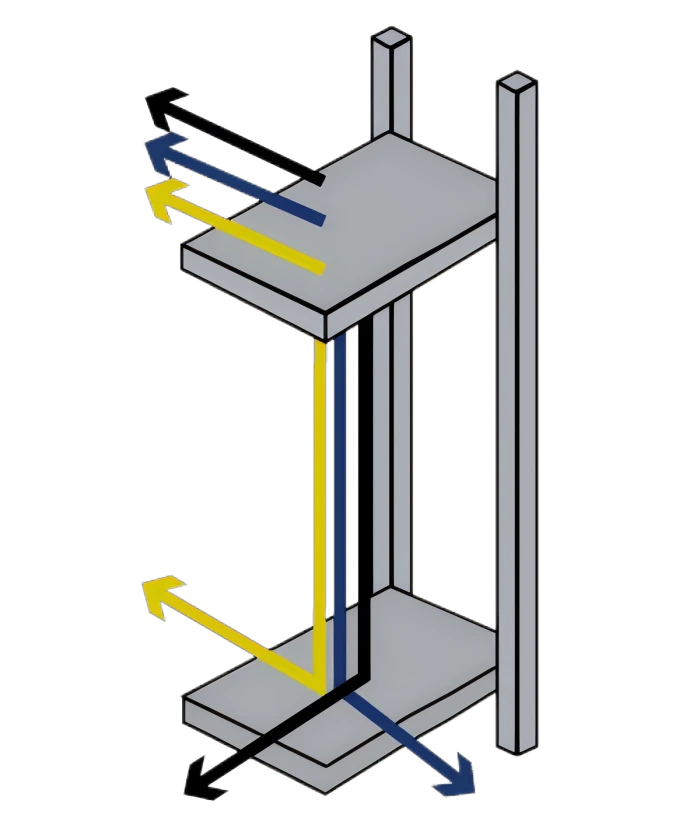

적재 및 하역 옵션: 다양한 물류 프로세스에 맞게 C형 언로딩(같은 쪽)과 Z형 언로딩(반대쪽)을 지원합니다.

다양한 화물 크기에 맞게 다용도로 사용 가능: 다양한 무게와 치수의 화물을 쉽게 처리할 수 있도록 설계되었습니다.

효율적인 수직 운송: 빠르고 안전하게 층간 물품을 이동하여 운영 효율성을 높입니다.

더 자세히 알고 싶으신가요? 도움이 되는

팀이 도와드리겠습니다.

견적 요청하기

수직 왕복 컨베이어 제품군 보기

02

VRC 캔틸레버 리프트

용량: ≤ 2000kg

플랫폼 크기: 사용자 지정

리프트 높이: 최대 15m

리프팅 속도: ≥40m/min

플랫폼 크기: 사용자 지정

리프트 높이: 최대 15m

리프팅 속도: ≥40m/min

03

4포스트 C형 VRC 리프트

용량: 3-20톤

플랫폼 크기: 사용자 지정

리프트 높이: 최대 30m

리프팅 속도: 0.1~0.5m/s

플랫폼 크기: 사용자 지정

리프트 높이: 최대 30m

리프팅 속도: 0.1~0.5m/s

04

4포스트 E형 VRC 리프트

용량: 3-20톤

플랫폼 크기: 사용자 지정

리프트 높이: 최대 50m

리프팅 속도: 0.2-1.0 m/s

플랫폼 크기: 사용자 지정

리프트 높이: 최대 50m

리프팅 속도: 0.2-1.0 m/s

05

4포스트 Z형 VRC 리프트

용량: 5-25톤

플랫폼 크기: 2.5-6m(폭) × 1.8-4m(깊이)

리프트 높이: 최대 20m

리프팅 속도: ≥30m/min

플랫폼 크기: 2.5-6m(폭) × 1.8-4m(깊이)

리프트 높이: 최대 20m

리프팅 속도: ≥30m/min

VRC 사례 보기

수직 왕복 컨베이어 자주 묻는 질문

02

수직 왕복 컨베이어를 설치하려면 구조 변경이 필요합니까?

수직 왕복 컨베이어(VRC)를 설치하려면 설계, 용량 및 설치 환경에 따라 구조적 수정이 필요할 수 있습니다. 아래는 전문가의 분석입니다:

VRC 설치를 위한 구조적 요구 사항

바닥 보강

- 경량 VRC(1,000파운드/450kg 미만): 국부적인 바닥 강화(예: 강판 또는 크로스 브레이싱)만 필요할 수 있습니다.

- 고하중 VRC(2,000파운드/900kg 초과): 하중을 안전하게 분산하기 위해 콘크리트 기초 또는 강철 I빔 지지대가 필요합니다(ANSI/ASME B20.1에 따름).

수직축 고려 사항

- 가이드 시스템: 건물 기둥 또는 가이드 레일 전용 강철 프레임워크와 구조적으로 정렬해야 합니다.

- 클리어 높이: 최소 머리 위 공간(일반적으로 이동 경로 위 12~18인치)을 유지해야 합니다.

03

VRC의 최대 무게는 얼마인가요?

| VRC 유형 | 표준 용량 범위 | 최대 용량* |

|---|---|---|

| 표준 산업용 VRC | 1,000 - 20,000파운드 (450 - 9,000kg) |

50,000파운드 (22,680kg) |

| 유압식 VRC | 5,000 - 30,000파운드 (2,270~13,600kg) |

100,000파운드 (45,360kg) |

04

VRC 비용은 얼마인가요?

위 가격은 VRC의 평균 시장 가격을 나타내며 Gradin의 가격을 반영하지 않습니다. 구체적인 가격은 전문가 팀에 문의하시기 바랍니다.

| VRC 유형 | 용량 범위 | 기본 가격 범위* | 주요 비용 동인 |

|---|---|---|---|

| 표준 전기 VRC | 1,000-5,000파운드 (450~2,270kg) |

$15,000 – $35,000 | 플랫폼 크기, 리프트 높이, 제어 시스템 |

| 유압식 산업용 VRC | 5,000~20,000파운드 (2,270-9,070kg) |

$40,000 – $85,000 | 호스/펌프 용량, 구조적 보강재 |

| 맞춤형 헤비 듀티 VRC | 20,000-100,000파운드 이상 (9,070-45,360+ kg) |

$90,000 – $250,000+ | 특수 가이드, 방폭, 자동화 |

중요한 비용 구성 요소:

- ✓ 드라이브 시스템: 전기식(15% 더 저렴) vs 유압식(더 높은 듀티 사이클)

- ✓ 리프트 높이: 추가 층당 $800-$1,500 추가(≥10피트/3m)

- ✓ 컨트롤: 기본 펜던트($1.5k) 대 PLC 자동화($8k-$15k)

- ✓ 안전 기능: ANSI 규격 게이트(+$3k), 라이트 커튼(+$4.5k)