10.22.2025 / 6분 읽기

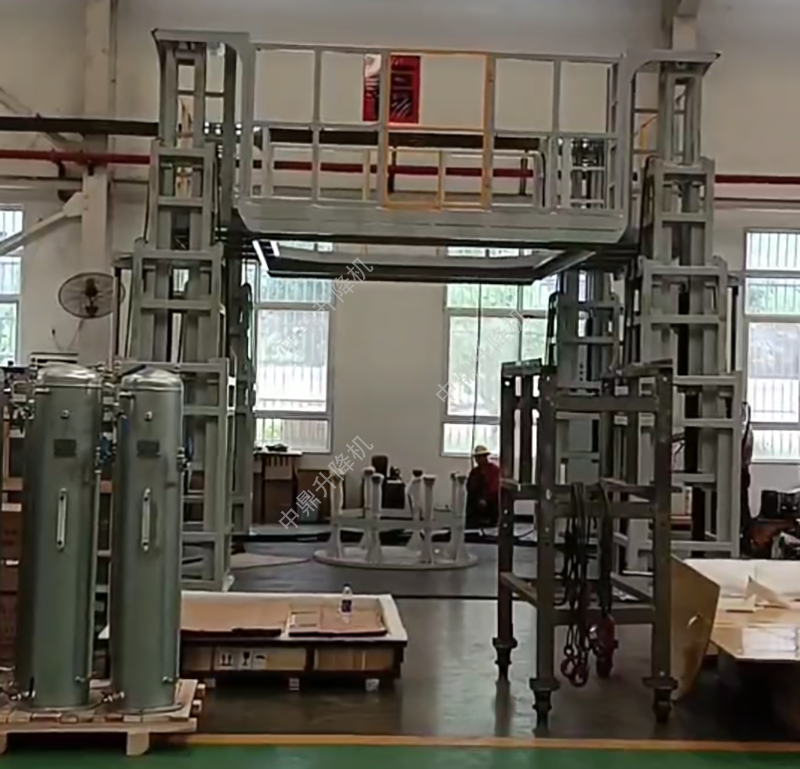

유압 코어 터닝 및 적재 테이블 | 1-100톤

개요

이 사례 분석에서는 유압식 코어 터닝 및 스태킹 테이블이 기존 변압기 코어 제조의 핵심 과제를 해결하여 중소형 변압기 생산의 효율성과 품질을 혁신적으로 개선하는 방법을 자세히 살펴봅니다.

모듈식 설계, 정밀한 유압 제어, 강력한 공정 적응성, 탁월한 구조적 신뢰성을 갖춘 유압 코어 터닝 및 스태킹 테이블은 현대 변압기 코어 생산 라인에서 없어서는 안 될 핵심 자산으로 자리 잡았습니다. 단순히 고품질의 코어 제조를 달성하기 위한 도구가 아니라 변압기 생산에서 공정 발전과 비용 효율적인 효율성 향상을 이끄는 원동력입니다.

기본 매개변수

| 매개변수 카테고리 | 사양 항목 | 세부 정보 및 사양 |

|---|---|---|

| 핵심 사양 | 부하 용량 | 1 ~ 100톤(사용자 지정 가능) |

| 호환 가능한 코어 유형 | 3상 코어, 5라임 코어, 라미네이션 | |

| 플랫폼 구조 | 모듈형 블록 조합(대형), 모노블록 디자인(소형) | |

| 정밀도 지표 | 테이블 표면 변형 | < 2mm 미만 |

| 직각도(스태킹 테이블 대 터닝 빔) | < 2mm 미만(회전 전 및 후) | |

| 기계 및 구조 | 빔 조정 | 양쪽에서 동시에 움직이는 빔 |

| 드라이브 시스템 | 유압 실린더 구동 선삭 | |

| 회전 속도 | 조정 가능 | |

| 안전 기능 | 회전 지지 다리(90° 회전 후 안정성을 위한) | |

| 프레임 재질 | 열간 압연 강철 또는 저탄소 용접 구조, 응력이 완화됨 | |

| 유압 시스템 | 주요 구성 요소 | 수입 브랜드 유압 부품(예: 실린더) |

| 동기화 | 뛰어난 동기화, 다음을 보장합니다. 변형 없는 코어 | |

| 설치 및 적응성 | 설치 요구 사항 | 라지: 대형: 파운데이션 필요, 소형: 파운데이션 없음, 이동 용이 |

| 핵심 창 적응성 | 코어 창 크기에 따라 유연하게 조립할 수 있습니다, 높은 적응성 | |

| 테이블 표면 치수 | 고객 요구 사항에 따라 맞춤 설정 | |

| 프로세스 호환성 | 호환되는 프로세스 | 적합 대상 탑 요크 비제거 프로세스 기존 프로세스 |

| 픽스처 호환성 | 뛰어난 동기화 보장 변형 없는 코어 |

과제 및 솔루션

- 전통적인 도전 과제: 기존의 코어 적재 및 회전은 오버헤드 크레인과 수작업에 크게 의존하여 비효율성, 동기화 불량, 잠재적 위험으로 이어졌습니다. 코어 변형안전 위험이 높고 다양한 창 크기에 대한 적응성이 떨어집니다.

- 프로세스 최적화: 이 테이블을 사용하면 코어가 수평인 상태에서 스트랩을 묶을 수 있으므로 수직 묶는 데 사용되는 복잡한 보조 클램프가 필요하지 않아 작업이 간소화되고 사이클 시간이 단축됩니다. The 동기식으로 움직이는 빔 양쪽의 코어 기둥 직경(MO)에 맞게 정밀하게 조정되어 폭넓은 적용성을 보장합니다.

신뢰성 설계

- 핵심 구성 요소 신뢰성: 중요 유압 부품(예: 실린더)은 수입 브랜드를 사용합니다.를 통해 장기적인 운영 안정성을 보장하고 높은 신뢰성 을 사용하여 장애 발생률을 줄입니다.

- 구조적 강도 및 정밀도: 유한요소해석(FEA)은 설계 최적화에 사용되어 하중(1~100톤) 하에서 충분한 강도와 강성을 보장합니다. 테이블 변형 2mm 미만, 회전 전후 직각도 오차 2mm 미만 등의 고정밀 지표는 코어 적재 품질을 위한 견고한 기반을 제공합니다. 회전 지지 다리의 설계로 90도 회전 후 추가적인 안전 보호 기능 제공