7.8.2025 / 5분 읽기

빈 페트병 컨베이어 시스템|고속 수직 리프트

개요

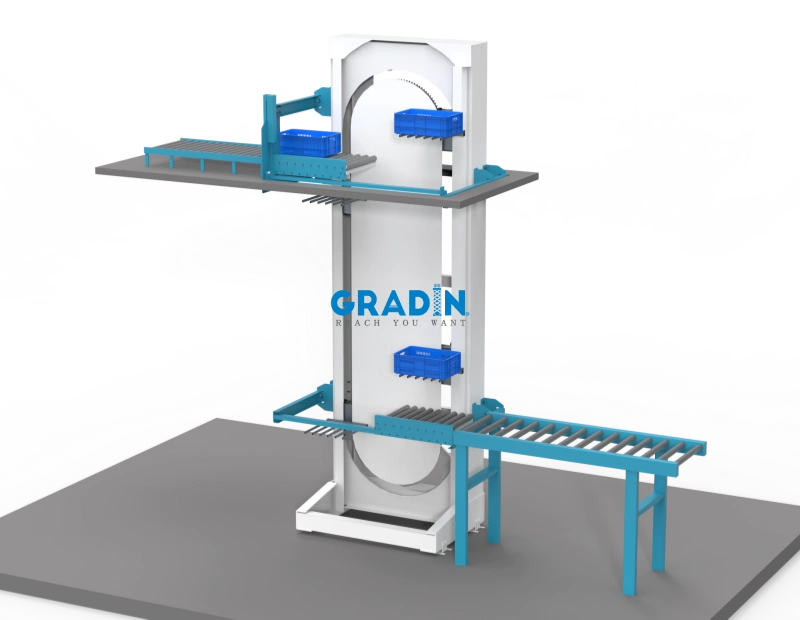

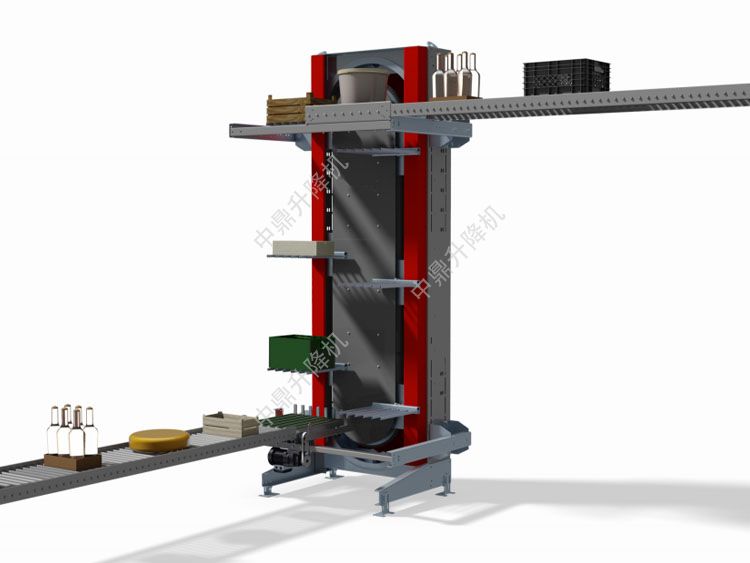

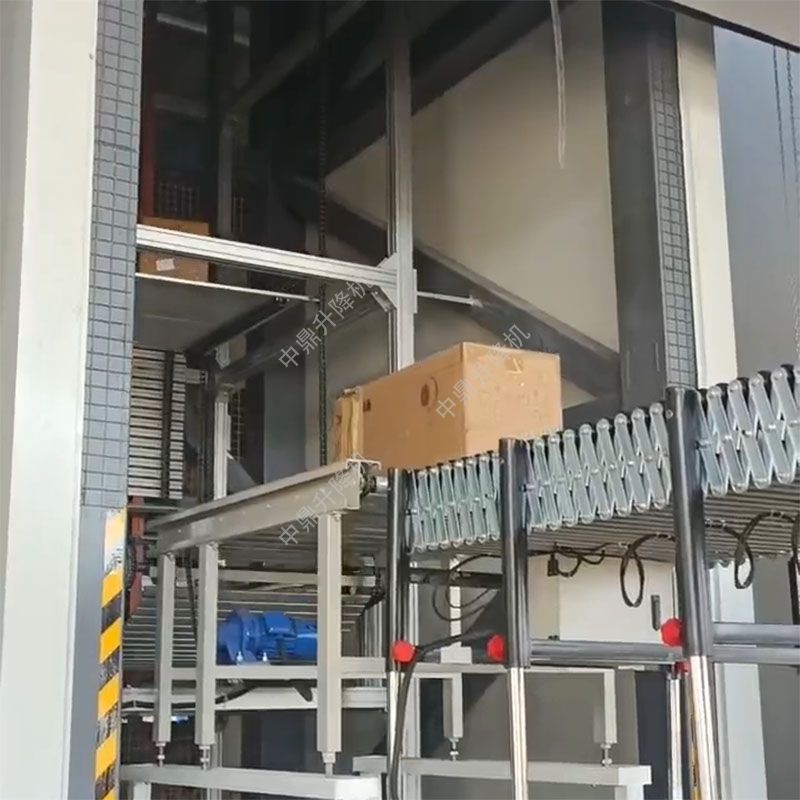

빠른 속도 포크 암 연속 수직 컨베이어 생수 공장용으로 설계되었습니다. 회전 포크 메커니즘이 있어 충전, 캡핑, 팔레타이징 스테이션 간에 빈/충진 용기를 빈틈없이 운반할 수 있습니다. 시간당 20,000병 이상의 용량으로 엄격한 위생 기준을 충족합니다.

- ✅ 수작업 대체, 병 기울임 방지

- ✅ 건식 설계(무급유)로 물 오염 방지

- ✅ 모듈식 구조로 페트병/5갤런 용기에 맞게 조정 가능

기본 매개변수

| 매개변수 | 사양 범위 | 단위 | 참고 |

|---|---|---|---|

| 용량 | 15,000 – 36,000 | 병/h | 500ml 페트 기준 |

| 컨테이너 유형 | PET/PC 병, 5갤런 용기 | – | Ø50-300mm |

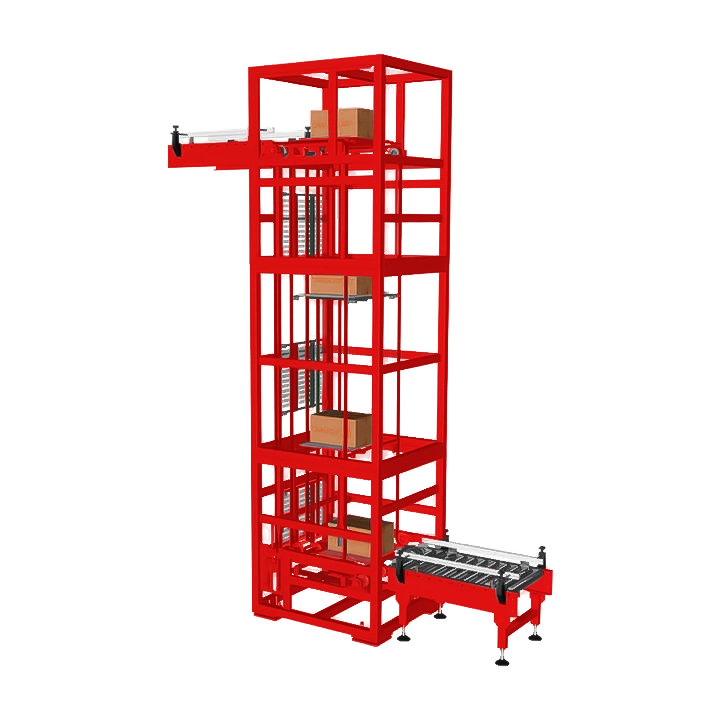

| 리프트 높이 | 3 – 20 | m | 2~6층 커버리지 |

| 작동 속도 | 0.25 – 0.8 | m/s | 서보 모터 제어 |

| 포지셔닝 Acc. | ±1 | mm | 채우기 라인 요구 사항 |

| 재료 | SS304(접촉면) | – | Ra≤0.4μm 전기 연마 |

| 전원 | 5.5 – 18.5 | kW | 부하/속도에 따라 다름 |

기술적 이점

- ⚡ 지속적 효율성:

- 회전 포크 설계로 대기 시간 제로 (40%↑ vs 왕복)

- 비어있는 컨테이너와 가득 찬 컨테이너의 동시 흐름을 위한 듀얼 독립 채널

- 🛡️ 위생 안전:

- IP69K 세척 보호 기능을 갖춘 밀폐형 스테인리스 하우징

- 오일 프리 작동: 자체 윤활 폴리머 베어링 + 식품 등급 드라이 체인

- 🎯 정밀한 핸들링:

- 자동 조절식 포크 피치(50-300mm)

- 병목 그립퍼(기울기율<0.01%)

- 📊 스마트 커넥티비티:

- 필러와 실시간 PLC 동기화(OEE≥95%)

- 컨테이너 전환 메모리(3초 자동 조정)

일반적인 애플리케이션

- 빈 젖병 수유: 디팔렛타이징 구역 → 2층 병 세척기 입구

- 채우기 인터페이스: 필러 배출 → 캡퍼 인피드 상승

- 전체 저그 처리: 5갤런 충전 라인 → 3층 포장/팔레타이징

- 포장 공급: 캡/라벨 릴의 수직 운송

핵심 혜택

| 차원 | 주요 지표 |

|---|---|

| 효율성 | 100% 회선 동기화|다운타임 제로 |

| 비용 절감 | 12명의 작업자/라인 절감|98% 파손 감소($70K+/년) |

| 품질 보증 | 100% 노터치 취급|오염 위험 제로 |

| 공간 절약 | 설치 공간 2.5×3m(엘리베이터 샤프트 대비) |

사용자 지정 옵션

| 사용자 지정 | 생수 포커스 | 표준 옵션 |

|---|---|---|

| 컨테이너 적응 | PET 팁 방지 그리퍼|저그 지지 암 | 유리/캔 특수 도구 |

| 위생 클래스 | CIP 멸균|미러 광택(Ra≤0.2μm) | SS316L/2205 |

| 속도 업그레이드 | Ultra-HS 버전(50,000병/h) | VFD/서보 드라이브 선택 |

| 환경 | 고습도(95%RH)|결로 방지 | ATEX/실외 |

| 스마트 기능 | 비전 컨테이너 ID|AI 잼 방지 | MES/ERP 통합 |