9.9.2025 / 5분 읽기

8톤 중량 부품 선삭기 - 기어 제조용 정밀 선삭 장비

개요

이 사례 분석에서는 8톤 중장비 터닝 머신에 대해 자세히 설명합니다.

다음과 같은 무거운 부품의 정밀 처리를 위해 특별히 설계되었습니다. 전동 휠를 통해 가공 중 대형 기어형 부품의 다각도 위치 결정 문제를 해결합니다. 혁신적인 U-그루브 플랫폼 멀티 툴링 시스템.

기본 매개변수

| 매개변수 | 값/설명 |

|---|---|

| 정격 부하 | 8000 kg |

| 플랫폼 크기 | 2000*2000+2000*2000mm |

| 회전 각도 | 90도 |

| 회전 속도 | <50초/주기 |

| 드라이브 파워 | 3KW SEW 브랜드 감속기 모터 |

| 메인 프레임 재질 | J200*100*6 스틸 섹션 |

| 플랫폼 두께 | 8mm |

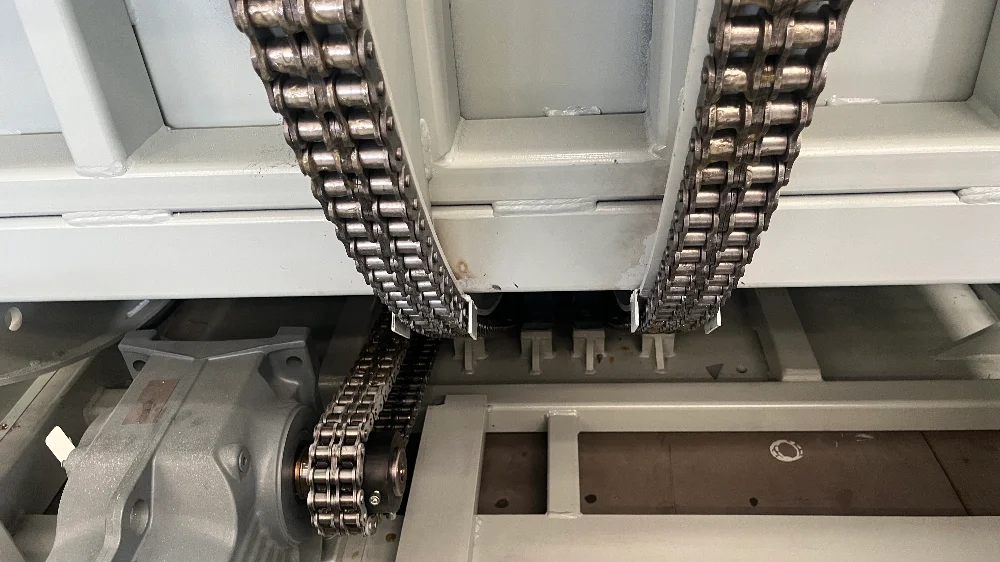

| 체인 사양 | 20A-2 |

| 제어 시스템 | 슈나이더 일렉트릭 구성 요소 |

| 장비 색상 | RAL7035 |

작동 방식

이 장비는 모터 감속기 구동 체인 전송 시스템을 사용하여 정밀한 90도 플랫폼 회전을 실현합니다.

한 플랫폼에는 맞춤형 U-홈과 T-슬롯이 있고 다른 플랫폼에는 탈착식 V-홈과 장력 조절 장치가 장착되어 있어 다양한 공작물 사양에 맞출 수 있습니다.

운영자는 조그 제어 기능이 있는 외부 핸드헬드 버튼 박스를 통해 시스템을 제어합니다.

도전 과제

- 전동 휠과 같은 대형 부품은 수동 회전 시 안전 위험을 초래합니다.

- 기존 터닝 장비는 정밀 위치 결정 요구 사항을 충족할 수 없습니다.

- 사양에 따라 다양한 클램핑 및 고정 방법이 필요합니다.

- 제조 공정에는 여러 차례의 회전과 정밀한 위치 지정이 필요합니다.

- 장비 이동성 및 조정 어려움은 작업장 레이아웃 유연성에 영향을 미칩니다.

솔루션

- 정밀 포지셔닝: U-홈 + T-슬롯 + V-홈 멀티 툴링 설계로 공작물 안정성 보장

- 안전한 작동: 슈나이더 전기 제어 기능이 있는 SEW 드라이브 시스템으로 작동 신뢰성 보장

- 효율적인 선회50초 내 90도 회전으로 생산 효율성 향상

- 모바일 디자인: 베이스의 지게차 슬롯으로 장비 재배치 용이

- 다양한 적응: 탈착식 V-홈 및 텐셔너로 다양한 공작물 요구 사항 수용 가능

- 안전 보장자동 잠금 기능이 있는 8톤 잠금 스트랩으로 작동 안전 보장