16.10.2025 / 4-minute read

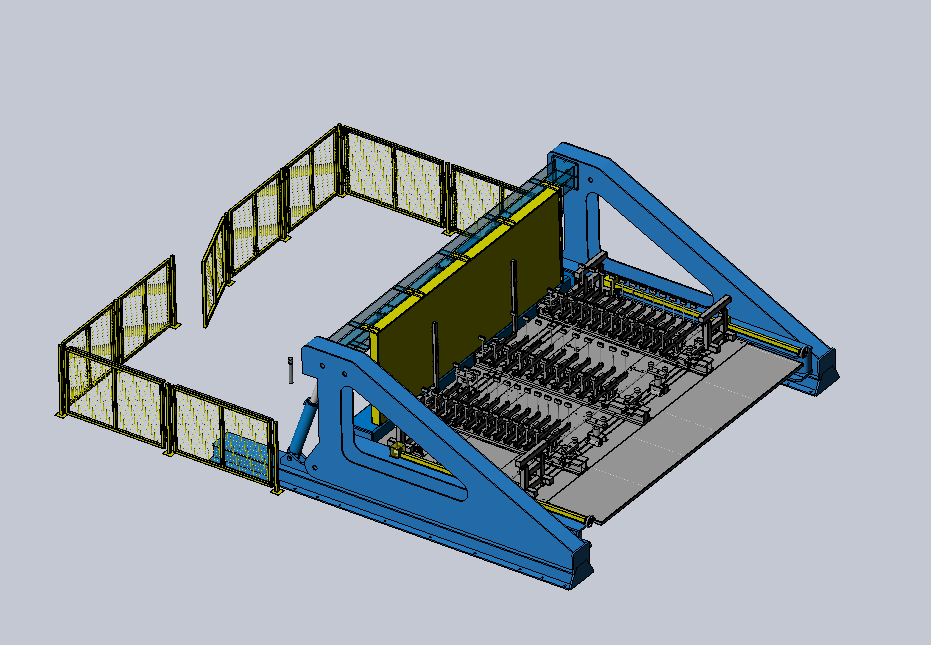

Hydraulic Iron Core Tilting Table System

Overview

The Hydraulic Iron Core Tilting Table System is a specialized industrial solution designed for the assembly, turning, and vertical positioning of large transformer cores, including two- and three-column configurations.

It integrates a hydraulic tilting platform, stacking platform, motorized lifting support, and auxiliary tooling to streamline transformer manufacturing processes

Basic Parameters

| Parameter | Value/Specification |

|---|---|

| Rated Load | 50 tons (core net weight) |

| Max Core Size | 4300×3400mm |

| Stacking Table Size | 3500×4300×1250mm |

| Turning Angle | 0-90 degrees |

| Angle Accuracy | ±0.5° |

| Turning Time | ≤10 minutes (adjustable) |

| Hydraulic Power | ≤55KW |

| Working Pressure | 18-25MPa |

| Flatness Accuracy | ≤3mm (under 50-ton load) |

| Service Life | >30 years |

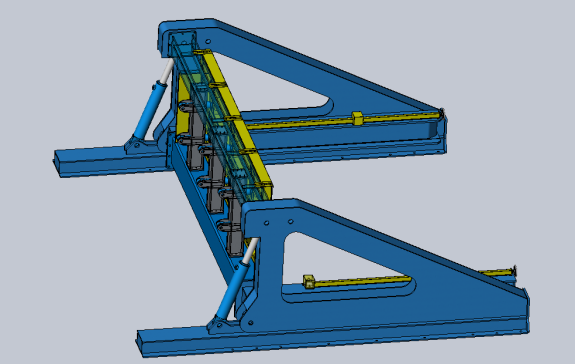

⚙️ Efficient and Safe Hydraulic Tilting Mechanism

- Hydraulic Drive & Stability: The system uses an oil cylinder-based flipping mechanism, ensuring smooth and stable operation without relying on overhead cranes. This saves space and reduces dependency on crane operators.

- Safety Features: Equipped with hydraulic self-locking, self-check, and explosion-proof valves to prevent instability or vibration. In case of power failure, the core safely resets to a flat/upright position using its own weight.

- Precision Control: Flip speed is adjustable, and the table’s deformation during operation is kept under 2mm, maintaining structural integrity and alignment accuracy.

🏗️ Robust and Durable Structural Design

structural steel and plates

- High-Strength Materials: Main components are welded from structural steel and plates, optimized via finite element analysis for load-bearing reliability.

- Precision Machining: Key surfaces are processed using large CNC boring and milling machines to ensure flatness and alignment. Welded structures undergo stress relief through aging treatment to minimize deformation.

- Corrosion Protection: Sandblasting and anti-rust painting processes (e.g., red oxide primer, blue/green topcoat) enhance durability and provide a clean, professional appearance.

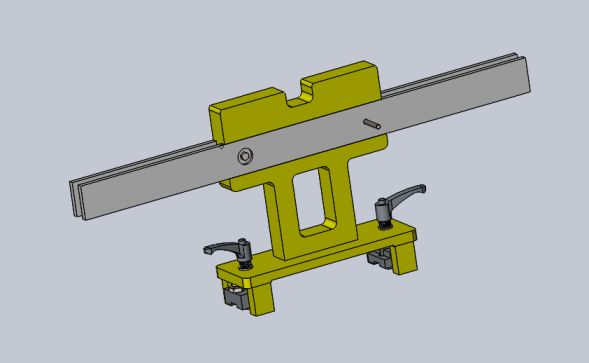

🔩 Fast Alignment and Secure Locking System

Central Limb Support Tooling

Central Limb Support Tooling

- Operator Safety: Fitted with safety fences, light curtains, and interlock switches. Hazard zones are marked with warning colors and signs.

- Hydraulic System Maintenance: The oil tank features a leak-resistant design, and filters can be replaced easily without major downtime.

- Routine Care Tips: Regularly clean surfaces with a lint-free cloth and alcohol, avoid impacts or overloads, and apply anti-rust oil when not in use—practices similar to maintaining cast iron T-slot platforms.

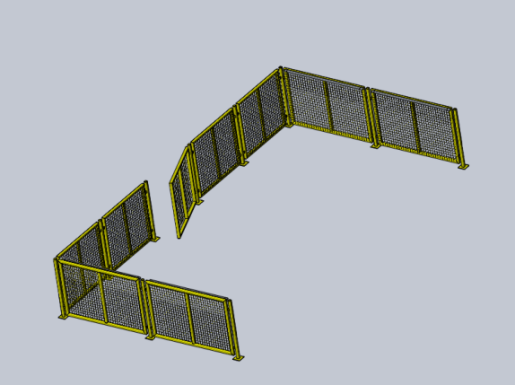

🛡️ Reliable Safety Protection and Easy Maintenance

Safety Fence

- Operator Safety: Fitted with safety fences, light curtains, and interlock switches. Hazard zones are marked with warning colors and signs.

- Hydraulic System Maintenance: The oil tank features a leak-resistant design, and filters can be replaced easily without major downtime.

- Routine Care Tips: Regularly clean surfaces with a lint-free cloth and alcohol, avoid impacts or overloads, and apply anti-rust oil when not in use—practices similar to maintaining cast iron T-slot platforms.

🎛️ Smart Electrical Control System

- Automated Control: Uses a Siemens S-series PLC with three operational modes: Production, Maintenance, and Debugging (access-controlled).

- Real-Time Monitoring: An industrial touchscreen displays live parameters: cylinder pressure, tilt angle, and fault alerts.

- Centralized Console: Includes emergency stop buttons, clearly labeled controls, and reliable wiring for safe, user-friendly operation.