7.8.2025 / Lecture en 5 minutes

Système de convoyage de bouteilles PET vides|High-Speed Vertical Lift

Vue d'ensemble

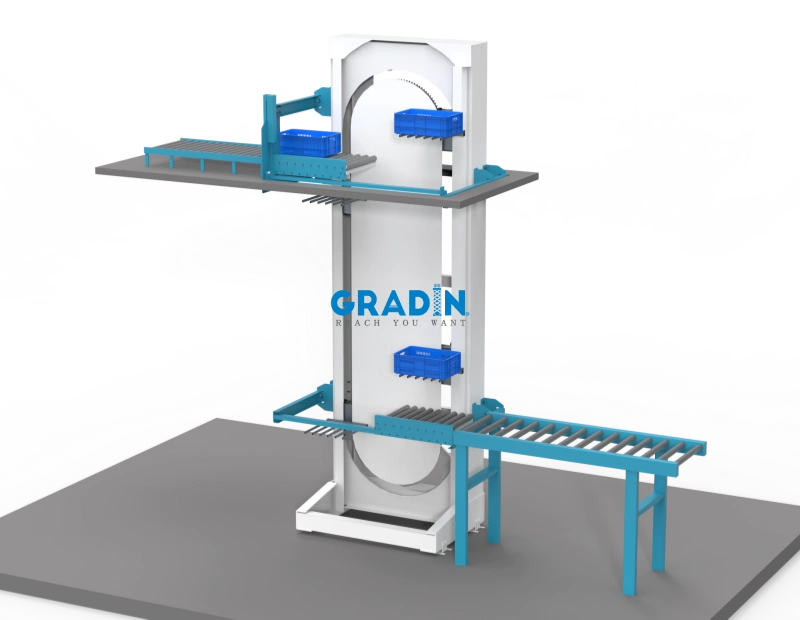

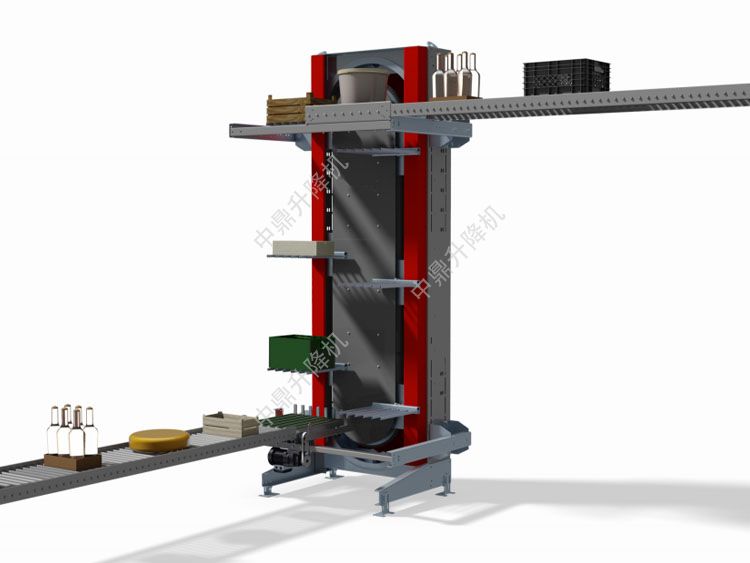

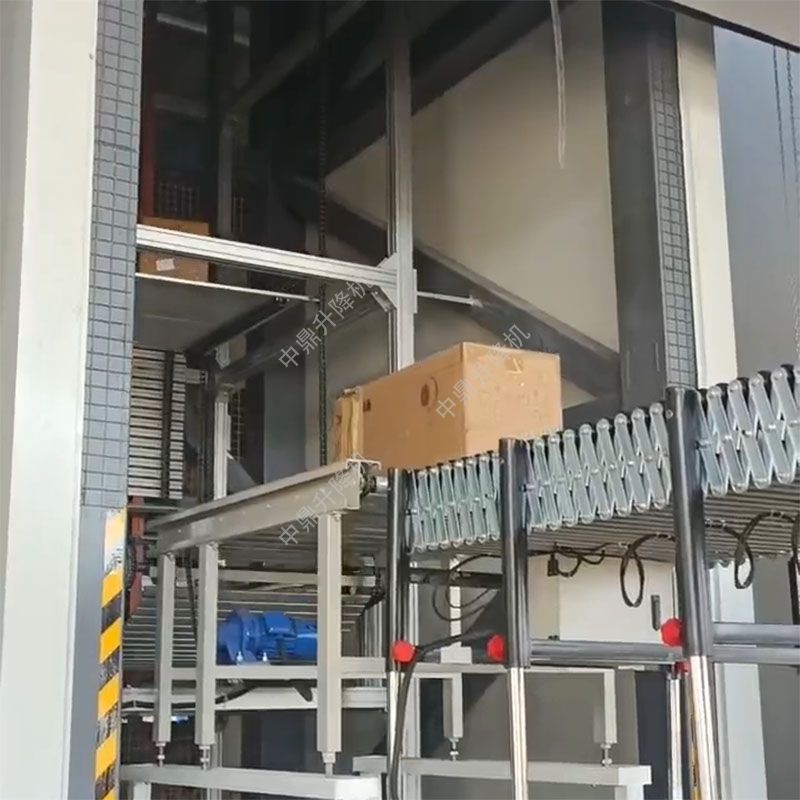

Haut débit convoyeur vertical continu à fourches conçu pour les usines d'eau embouteillée. Comprend des mécanismes de fourches rotatives pour le transport sans interstices de récipients vides ou remplis entre les stations de remplissage, de bouchage et de palettisation. Répond aux normes d'hygiène les plus strictes avec une capacité de plus de 20 000 bouteilles par heure.

- ✅ Remplace la manutention manuelle, élimine le renversement des bouteilles

- ✅ Le fonctionnement à sec (sans lubrification) évite la contamination par l'eau

- ✅ La structure modulaire s'adapte aux bouteilles PET et aux bidons de 5 gallons

Paramètres de base

| Paramètres | Gamme de spécifications | Unité | Notes |

|---|---|---|---|

| Capacité | 15,000 – 36,000 | bouteilles/h | Sur la base de 500ml PET |

| Types de conteneurs | Bouteilles PET/PC, bidons de 5 gallons | – | Ø50-300mm |

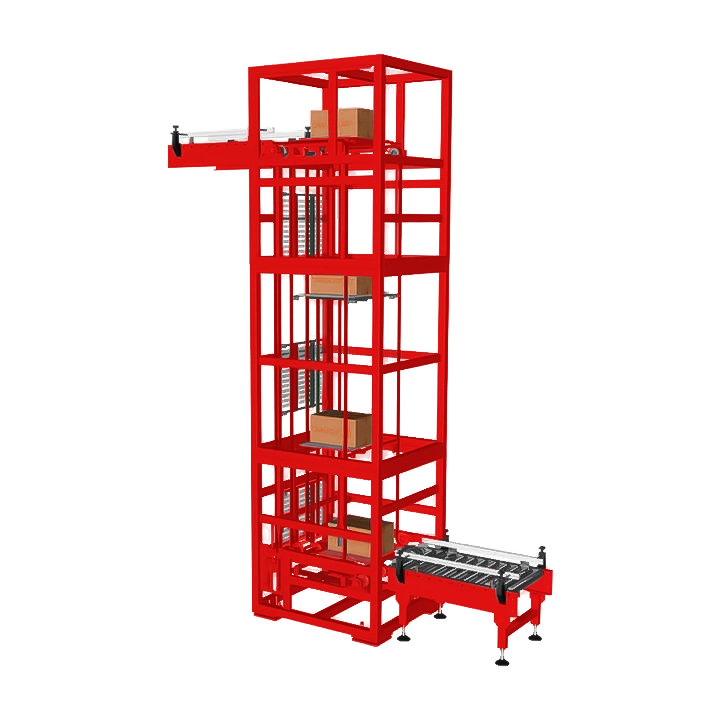

| Hauteur de levage | 3 – 20 | m | Couverture des étages 2-6 |

| Vitesse de fonctionnement | 0.25 – 0.8 | m/s | Commande de servomoteur |

| Positionnement Acc. | ±1 | mm | Exigences relatives à la ligne de remplissage |

| Matériau | SS304 (surfaces de contact) | – | Ra≤0.4μm électropoli |

| Puissance | 5.5 – 18.5 | kW | En fonction de la charge et de la vitesse |

Avantages techniques

- ⚡ Efficacité continue:

- La conception de la fourche rotative permet zéro temps d'attente (40%↑ vs alternatif)

- Deux canaux indépendants pour un écoulement simultané des conteneurs vides et pleins

- 🛡️ Sécurité hygiénique:

- Boîtier étanche en acier inoxydable avec protection contre le lavage IP69K

- Fonctionnement sans huile: Roulements en polymère autolubrifiants + chaînes sèches de qualité alimentaire

- 🎯 Manipulation de précision:

- Pas de fourche auto-réglable (50-300mm)

- Pinces à col de bouteille (taux de basculement<0,01%)

- 📊 Connectivité intelligente:

- Synchronisation en temps réel de l'automate avec les remplisseuses (OEE≥95%)

- Mémoire de changement de conteneur (réglage automatique en 3 secondes)

Applications typiques

- L'alimentation au biberon vide: Zone de dépalettisation → 2F Entrée du lave-bouteille

- Interface de remplissage: Décharge de la soutireuse → entrée de la capsuleuse surélevée

- Manipulation de la cruche pleine: Ligne de remplissage 5 gallons → ensachage/palettisation 3F

- Approvisionnement en emballages: Transport vertical de bouchons/rouleaux d'étiquettes

Prestations de base

| Dimension | Principaux indicateurs |

|---|---|

| Efficacité | 100% synchronisation de ligne|Zéro temps d'arrêt |

| Économies de coûts | 12 opérateurs/ligne économisés|98% de casse en moins ($70K+/an) |

| Assurance qualité | 100% manipulation sans contact|Risque de contamination nul |

| Économie d'espace | Empreinte au sol 2.5×3m (vs cage d'ascenseur) |

Options de personnalisation

| Personnalisation | L'eau en bouteille en point de mire | Options standard |

|---|---|---|

| Adaptation des conteneurs | Pince anti-basculement en PET|Bras de support de la pince | Verre/boîte outils spéciaux |

| Classe d'hygiène | Stérilisation CIP|Polissage au miroir (Ra≤0.2μm) | SS316L/2205 |

| Amélioration de la vitesse | Version Ultra-HS (50 000 bouteilles/h) | Sélection du variateur VFD/Servo |

| Environnement | Humidité élevée (95%RH)|Anti-condensation | ATEX/extérieur |

| Caractéristiques intelligentes | Conteneur de vision ID|AI prévention des bourrages | Intégration MES/ERP |