9.5.2025 / Lecture en 6 minutes

L'élévateur continu compact à mât unique - Une solution professionnelle de manutention verticale

Vue d'ensemble

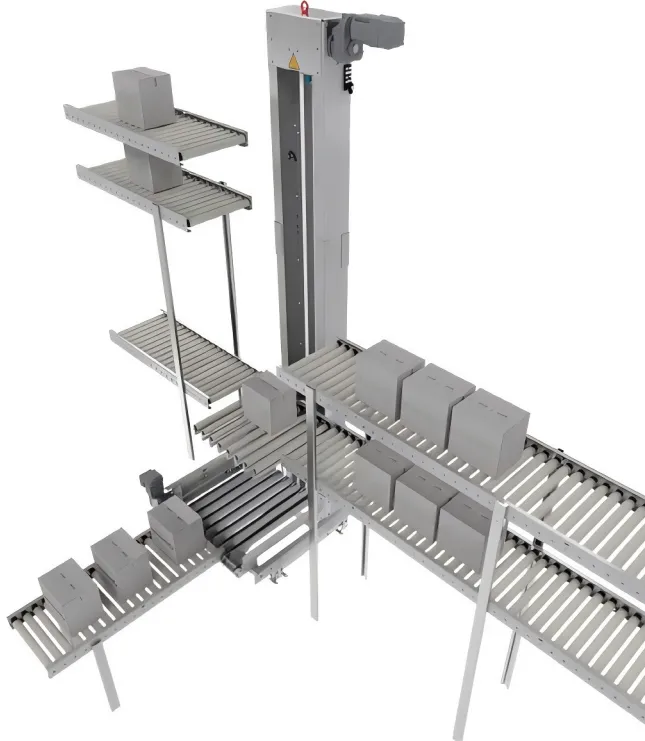

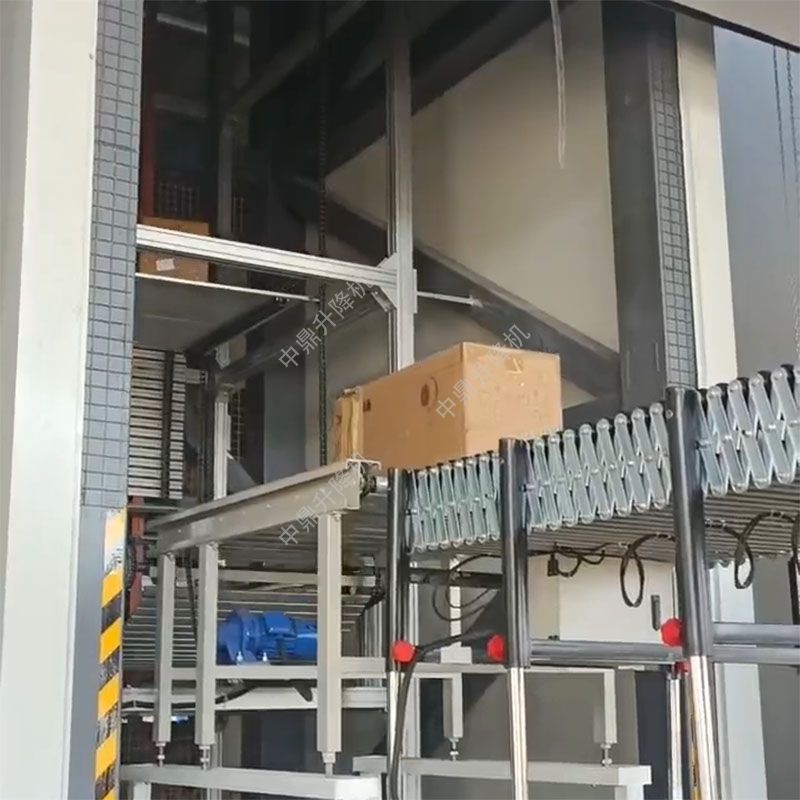

Cette analyse de cas présente la plate-forme de levage continue compacte à mât unique.

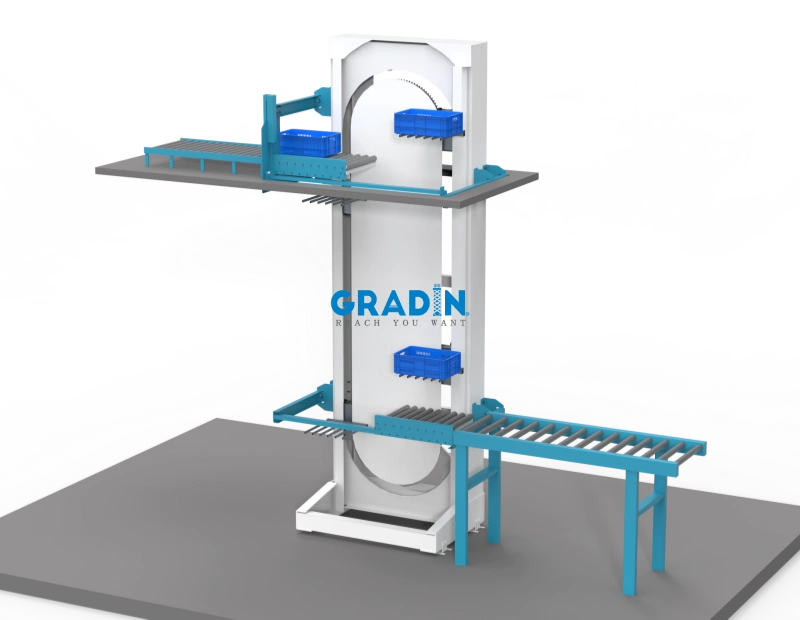

En tant que principal fournisseur de solutions de transport vertical, Gradin a conçu cet équipement spécifiquement pour environnements industriels à espace limité.

Notre produit démontre l'expertise technique de Gradin dans le domaine de la manutention et a été mis en œuvre avec succès dans diverses industries.

Paramètres de base

| Paramètres | Valeur/Spécification |

|---|---|

| Hauteur min. Hauteur d'entrée/sortie | 360 mm |

| Hauteur max. Hauteur d'entrée/sortie | 14 300 mm |

| Hauteur max. Hauteur de déplacement | 14 450 mm |

| Capacité de charge max. Capacité de charge | 100 kg |

| Max. Taille de l'article | 910 × 610 mm |

| Capacité max. Capacité | 360 cycles/heure |

| Options de direction | Gauche/droite/avant |

| Système d'entraînement | Entraînement par courroie silencieux Gradin |

Comment ça marche

Le système de levage Gradin utilise notre mécanisme exclusif à courroie pour un transport vertical continu.

Les matériaux sont chargés sur la plate-forme de transport et automatiquement élevés à la hauteur requise grâce à Le système de contrôle avancé de Gradin.

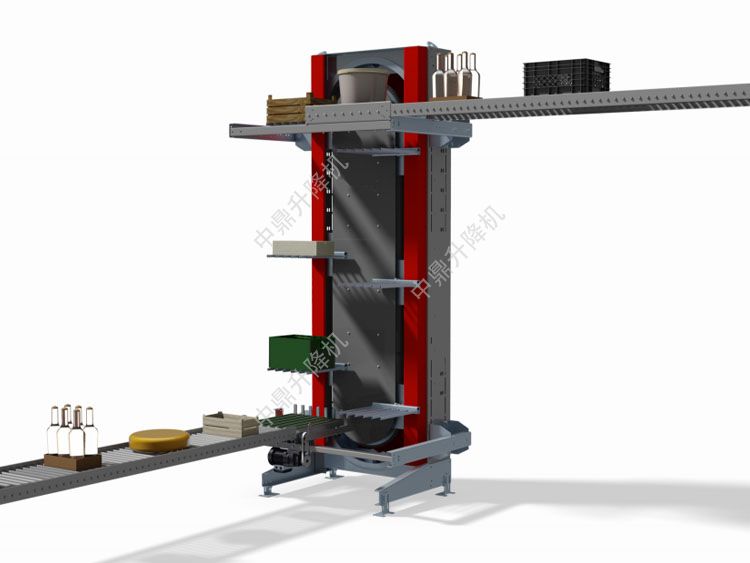

Notre conception modulaire permet plusieurs directions d'admission/de sortieLes convoyeurs à rouleaux fabriqués par Gradin s'intègrent parfaitement aux systèmes existants.

Les défis

- Contraintes d'espace limitant l'installation des équipements

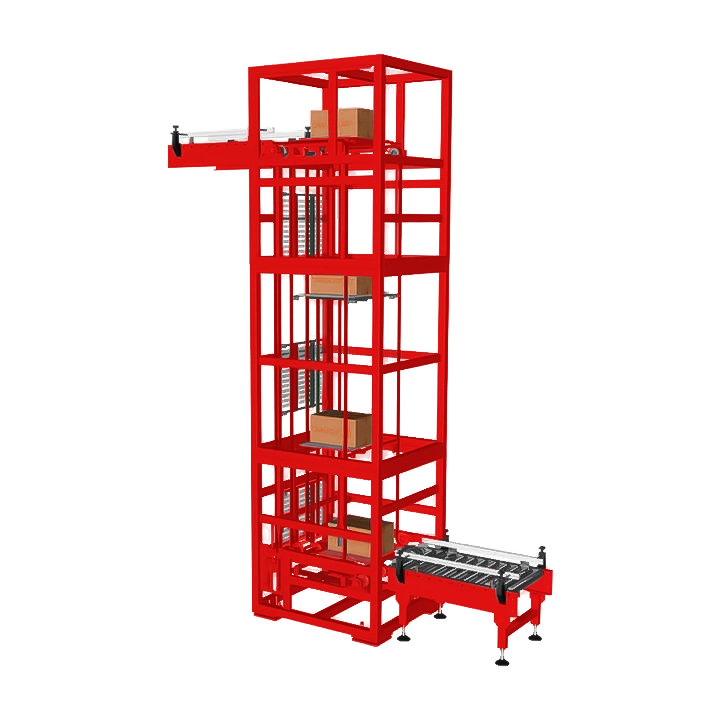

- Nécessité d'un transfert vertical continu des matériaux

- Niveaux de bruit élevés et exigences en matière d'entretien

- Besoin d'une manutention flexible

- Besoins d'intégration avec les systèmes existants

Solutions

- Conception peu encombrante: Notre structure compacte à mât unique

- Haute efficacité: Capacité de traitement de 360 cycles/heure

- Fonctionnement silencieux: Technologie exclusive de transmission par courroie de Gradin

- Flexibilité modulaire: Directions et hauteurs personnalisables

- Intégration transparente: Convoyeurs à rouleaux Gradin pour la compatibilité des systèmes

- Application polyvalente: Options de configuration multiples