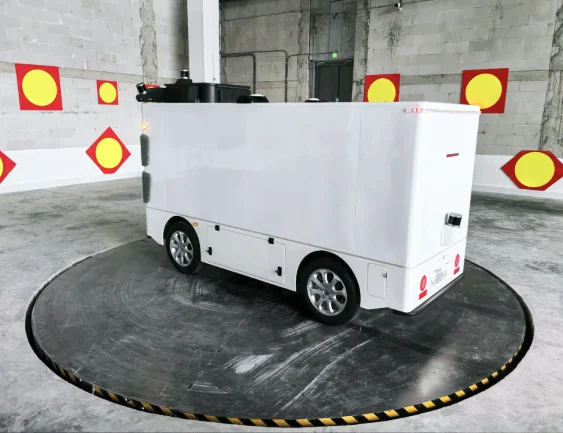

Grande plate-forme rotative

La plate-forme rotative de Gradin peut répondre aux différents besoins des utilisateurs en matière de rotation, assurer une rotation multi-angle de haute précision, réaliser des tests de rotation automatisés de haute précision et peut être utilisée pour les tests de post-production. Ce produit offre des services de personnalisation flexibles.

Pour en savoir plus parler à notre équipe

S'adapter à fonctionnement continu à haute fréquenceStructure compacte et stable, pouvant s'adapter à un fonctionnement continu à haute fréquence.

Contrôle électronique PLC: L'automate programmable peut contrôler avec précision le démarrage, l'arrêt et l'angle de rotation de la plate-forme rotative, ce qui convient aux situations nécessitant un positionnement de haute précision.

Régulation de la vitesse de conversion de la fréquence: Le mode de fonctionnement en douceur réduit l'usure de l'équipement et prolonge sa durée de vie.

Garantir fonctionnement sûrLe système de conversion de fréquence dédié, le démarrage et l'arrêt lents, garantissent un fonctionnement sûr et stable.

Rotation efficaceLe système permet de gagner de l'espace : La rotation est de 360°, ce qui convient particulièrement aux endroits où l'espace est limité, tels que les garages et les halls d'exposition.

Forte durabilité: Fabriqué en matériaux inoxydables et résistants à la corrosion, il convient à divers environnements.

Vous voulez en savoir plus ? Nos conseils

est là pour vous aider.

Demande de devis

Plate-forme tournante de grande taille questions fréquemment posées

Trois paquets d'adaptation environnementale :

- Protection IP66 : Paliers étanches avec revêtement hydrophobe

- Emballage thermique : Plage opérationnelle de -40°C à 120°C

- Antidéflagrant : Systèmes d'entraînement certifiés ATEX

Quadruple intégration de la sécurité :

- Contrôle dynamique de la charge : Analyse de la répartition du poids en temps réel

- Freinage redondant : Freins à disque électromagnétiques + mécaniques

- Positionnement d'urgence : Arrêt inertiel guidé par laser

- Système anti-collision : Balayage périmétrique LiDAR 360

Protocole de maintenance prédictive :

- Tous les jours : Contrôle de la température des roulements

- Hebdomadaire : Analyse de l'huile de boîte de vitesses

- Trimestrielle : Étalonnage du codeur

- Annuel : Tests de résistance structurelle