G-SJYZ0.5-6 6m Stahlschienenscherenhebebühne mit Auslegern

6m, 500kg, Electric, Steel Track

Steel tracks are more wear-resistant and durable than rubber tracks. This all-terrain, self-propelled scissor lift has an automatic walking function, allowing for fast and slow movement in different working conditions. During high-altitude operations, only one person is needed to operate the machine to continuously complete lifting, moving forward, reversing, turning, etc. The product features an aesthetically pleasing design, flexible mobility, simple operation, high load capacity, stable lifting, reliability, and safety.

G-SJYZ0.5-6 6m Stahlschienenscherenhebebühne mit Auslegern

Modelle und technische Daten

| Produkt-Parameter | G-SJYZ0.5-6 |

|---|---|

| Sichere Arbeitslast | 500kg |

| Erweiterte Plattform Sichere Arbeitslast | 100kg |

| Maximum Number of Persons | 3 |

| Maximale Arbeitshöhe | 8m |

| Maximale Plattformhöhe | 6 m |

| Overall Machine Length | 2.76m |

| Gesamtbreite der Maschine | 1.66m |

| Gesamthöhe der Maschine (Zaun nicht eingeklappt) | 2.41m |

| Gesamthöhe der Maschine (Zaun eingeklappt) | 1.8m |

| Größe der Arbeitsplattform (Länge x Breite) | 2.31.141.11m |

| Plattformverlängerung Größe | 0.9m |

| Minimum Ground Clearance (Retracted State) | 0.1m |

| Minimum Ground Clearance (Lifted State) | 0.02m |

| Radstand | 1.89m |

| Mindestwenderadius (Innenrad) | 0 |

| Mindestwenderadius (äußeres Rad) | 2.20m |

| Hebemotor/Antriebsmotor | 48v/4kw |

| Geschwindigkeit der Maschine (gefalteter Zustand) | 3.5km/h |

| Rising/Falling Speed | 3-5m/min |

| Storage Battery | 8×6V/200Ah |

| Charger | 45v/30A |

| Maximale Steigfähigkeit | 25% |

| Maximum Allowable Working Angle | X1.5°/Y3° |

| Maschine Gewicht | 3220kg |

Eigenschaften

Videos

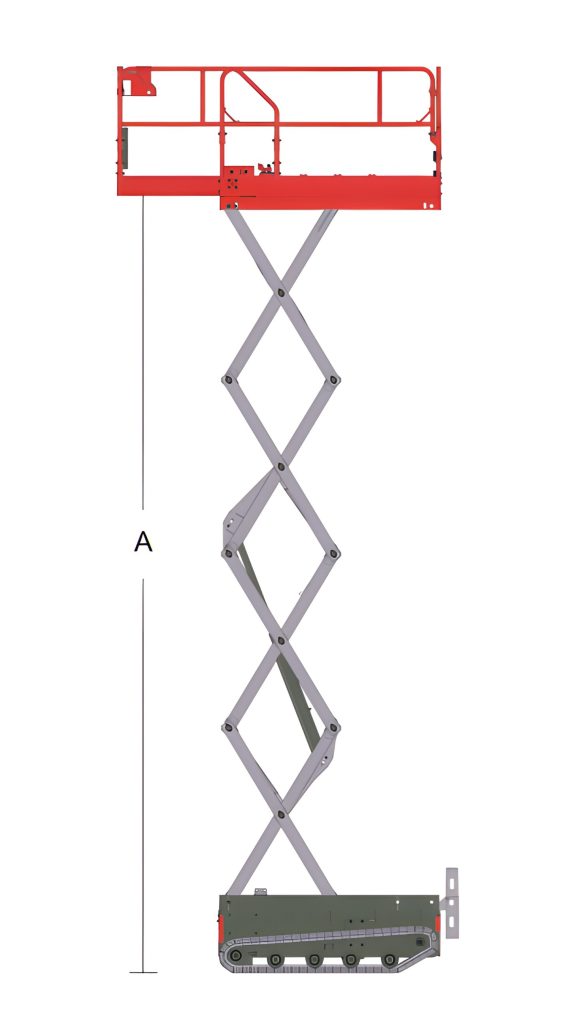

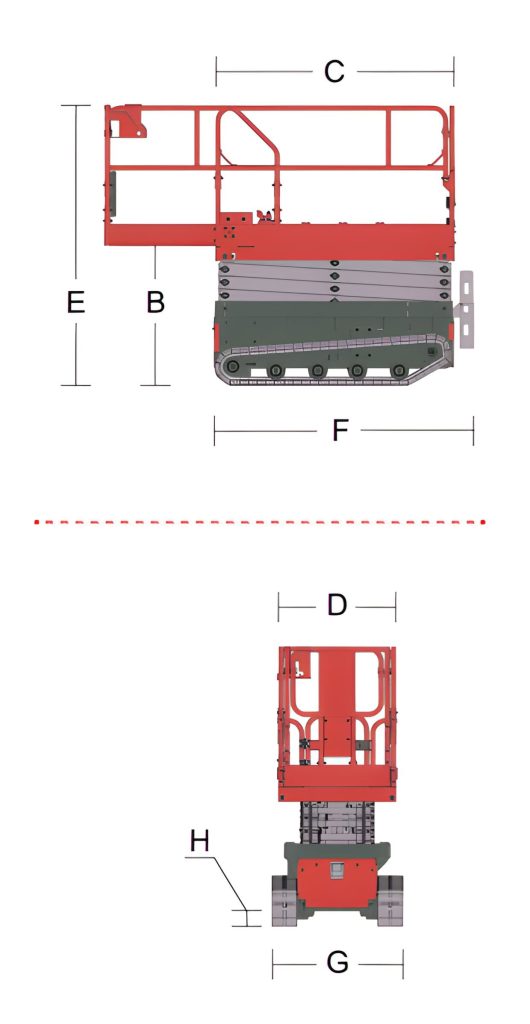

Größentabelle

G-SJYZ0.5-6 6m Stahlschienenscherenhebebühne mit Auslegern

Merkmale und Vorteile

Wear-Resistant Steel Tracks

Forged from high-strength alloy steel, the tracks deliver exceptional durability in harsh terrains (gravel, mud, debris). Outperforms rubber tires in traction and longevity, reducing replacement costs and downtime.

CE Certification

Fully compliant with EU safety directives, ensuring adherence to rigorous design, manufacturing, and operational standards for global market access and user safety.

Self-Propelled Mobility

Integrated drive system enables smooth forward/reverse movement and steering directly from the platform, eliminating manual pushing and boosting on-site efficiency.

Tilt Alarm System

Precision sensors monitor levelness and trigger audible/visual alerts when inclinations exceed safe thresholds. Automatically restricts operations to prevent tip-overs on slopes.

Burst-Proof Hydraulic Hoses

Steel-braided hoses with protective sleeves withstand extreme pressure and resist punctures, eliminating fluid leaks and ensuring system integrity.

Stufenlose Drehzahlregelung

Proportional joysticks enable seamless speed adjustment for lifting/travel motions, allowing millimeter-precision positioning in confined spaces.

IP67-Rated Metal Connectors

Corrosion-resistant waterproof plugs guarantee electrical reliability in wet/dusty environments, preventing short circuits.

CAN Bus Control System

Advanced digital network enables real-time communication between components, reducing wiring complexity while enhancing diagnostics and scalability.

Onboard Diagnostics

Continuous monitoring of critical components (motors, sensors, batteries) with instant fault code display for rapid troubleshooting and maintenance.

Emergency Stop Buttons

Strategically placed red mushroom buttons immediately cut power to all functions when pressed, ensuring fail-safe hazard response.

Disc Brake System

Hydraulic disc brakes deliver instant stopping power and reliable hold on inclines, preventing rollaways even under full load.

Extendable Platform

Optional slide-out deck extensions increase workspace by up to 40%, facilitating multi-worker operations and tool placement.