9.29.2025 / 5 Minuten lesen

Motortransportwagen: Flexible Logistik vom manuellen Schlepper zum halbautomatischen MGV

Übersicht

In dieser Fallstudie wird eine spezielle Transportlösung untersucht, die für den Transport hochwertiger Flugzeugtriebwerke innerhalb von Montageanlagen entwickelt wurde.

Es ermöglicht den sicheren und präzisen Transfer von Motoren und die nahtlose Integration mit kundenspezifischen Vier-Säulen-Motorliften.

Angeboten werden Konfigurationen von nicht motorisierte, manuell gezogene Versionen zu halbautomatische MGV-SystemeSie bietet ein effektives Gleichgewicht zwischen betrieblichen Anforderungen, Flexibilität und Kosteneffizienz für verschiedene Szenarien.

Grundlegende Parameter

| Parameter | Beschreibung |

|---|---|

| Hauptanwendung | Innerbetrieblicher Transfer und Andocken von Flugzeugtriebwerken |

| Fahrzeugtyp | Nicht angetriebene manuelle Version / Manual Guided Vehicle (MGV) |

| Stromquelle | Manuell: Externer Gabelstaplerzug; MGV: Bordbatterie und Antriebssystem |

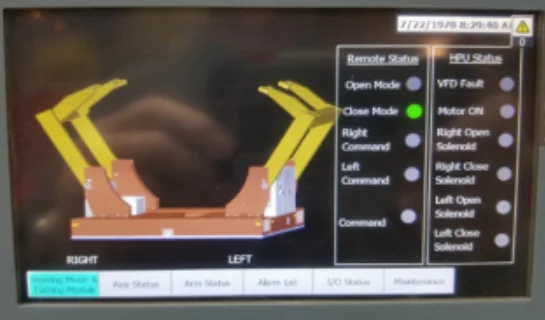

| Zentraler Mechanismus | Hydraulischer Anschluss und Motortragarme |

| Betriebsart | Manuell: Gabelstaplerzug; MGV: Handfernbedienung |

| Hauptmerkmal | Maßgeschneidert für Vier-Säulen-Aufzüge; MGV unterstützt Offline-Parken und -Laden |

Wie es funktioniert

- Be-/Entladen: Mit Hilfe seiner spezialisierten HydrauliksystemDas Fahrzeug verfügt über Tragarme, die mit einem Vier-Säulen-Motorlift verbunden sind. Die Arme heben oder senken den Motor sanft an und verriegeln ihn sicher auf dem Transportwagen.

- Transport:

- Manuelle Version: Ein Bediener verbindet den Wagen mit einem Gabelstapler über eine Schleppstange Montageund der Gabelstapler liefert die Antriebskraft für die Bewegung.

- MGV-Version: Ein Operator verwendet eine Handfernbedienung um das Fahrzeug zu steuern. Das bordeigene Steuersystem treibt die Räder an (z. B. Mecanum oder lenkbar) und ermöglicht eine präzise Bewegung zum Zielbahnhof.

- Parken und Wartung: Wenn er nicht in Gebrauch ist oder aufgeladen werden muss, kann der MGV selbst zu einem bestimmten Parkplatz fahren und so wertvolle Produktionsfläche freimachen.

Die Herausforderungen

- Sicherheit des Motors: Verhinderung von Stößen, Vibrationen oder Schlägen auf die äußerst wertvollen und empfindlichen Flugzeugtriebwerke während des Transports.

- Präzises Andocken: Millimetergenaue Ausrichtung mit speziellen Vier-Säulen-Hebebühnen für sicheres und effizientes Be- und Entladen.

- Flexibilität der Produktionslinie: Anpassung an sich dynamisch verändernde Montageprozesse, bei denen feste Förderer unpraktisch und traditionelle Methoden ineffizient sind.

- Optimierung von Raum und Kosten: Minimierung des Platzbedarfs der Einrichtung und Kontrolle der Investitionskosten bei gleichzeitiger Erfüllung aller funktionalen Anforderungen.

Lösungen

- Benutzerdefinierte Werkzeuge & Verriegelung: Maßgeschneiderte Motortragarme und ein hydraulischer Verriegelungsmechanismus sorgen dafür, dass der Motor während des Transports fest und sicher gehalten wird.

- Flexible Antriebskonfiguration: Zwei Antriebsoptionen decken unterschiedliche Bedürfnisse ab. Die manuelle Version bietet eine kostengünstige Lösung, während die MGV-Version bietet punktgenaue Genauigkeit und Bedienerfreundlichkeit über die Fernbedienung.

- Rationalisierte Prozessintegration: Das Design ist auf den Be- und Entladevorgang ausgerichtet, wodurch eine perfekte Kompatibilität mit der Vier-Säulen-Hebebühne gewährleistet ist und Engpässe zwischen den Arbeitsplätzen vermieden werden.

- Modulares und mobiles Design: Die selbstfahrende Version des MGV kann dynamisch eingesetzt werden, was die Auslastung der Werkstatt und die Flexibilität des Layouts erhöht.