9.5.2025 / 6-Minuten-Lesung

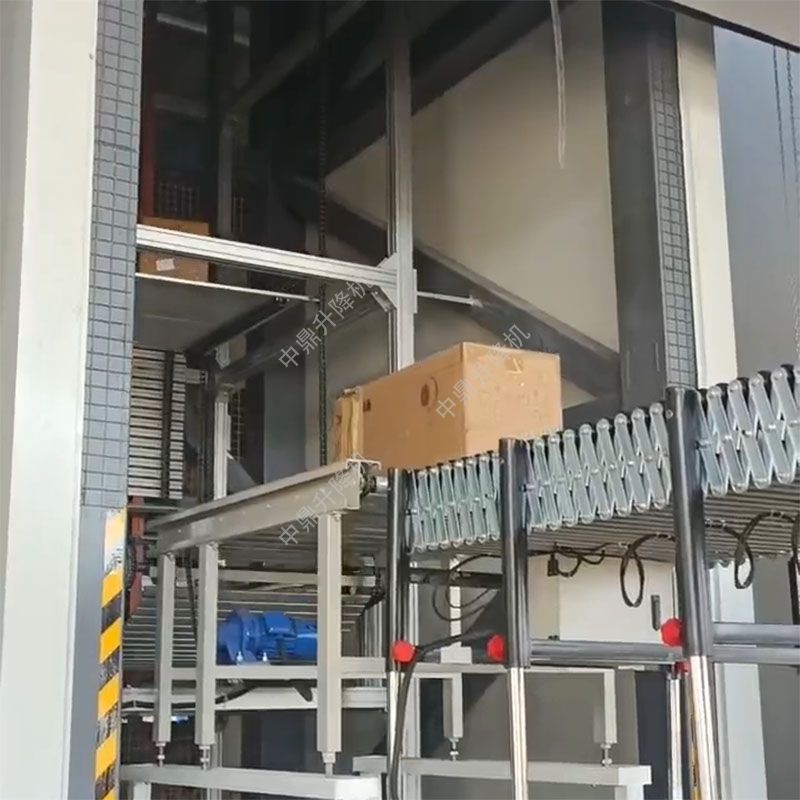

Kompakter Einmast-Stetigheber - Professionelle Lösung für den Vertikalumschlag

Übersicht

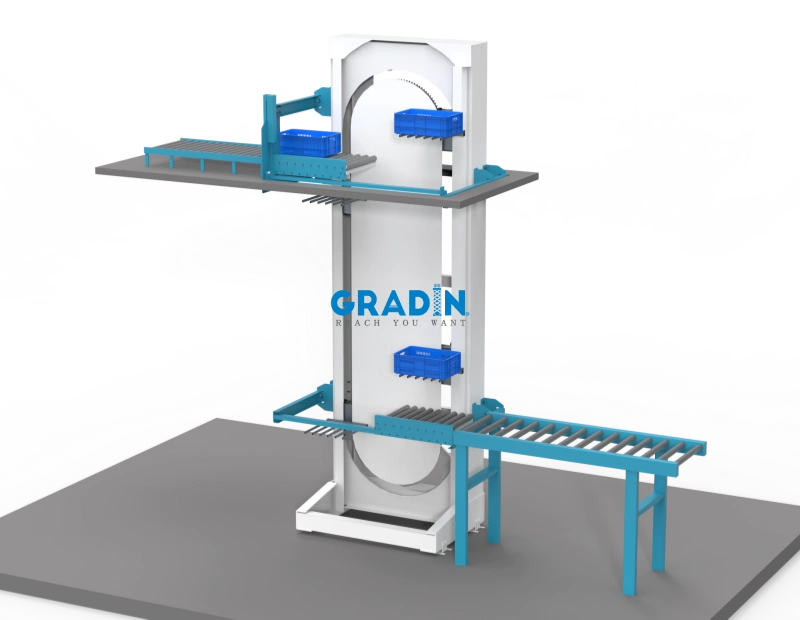

In dieser Fallanalyse wird die kompakte Einmast-Dauerhebebühne vorgestellt.

Als führender Anbieter von Vertikaltransportlösungen hat Gradin diese Ausrüstung speziell für platzbeschränkte industrielle Umgebungen.

Unser Produkt ist ein Beweis für die technische Kompetenz von Gradin im Bereich der Materialhandhabung und wurde bereits in verschiedenen Branchen erfolgreich eingesetzt.

Grundlegende Parameter

| Parameter | Wert/Spezifikation |

|---|---|

| Min. Ein-/Ausstiegshöhe | 360 mm |

| Max. Ein-/Ausstiegshöhe | 14.300 mm |

| Max. Hubhöhe | 14.450 mm |

| Max. Tragfähigkeit | 100 kg |

| Max. Artikel Größe | 910 × 610 mm |

| Max. Kapazität | 360 Zyklen/Stunde |

| Richtungsoptionen | Links/Rechts/Front |

| Antriebssystem | Gradin Leiser Riemenantrieb |

Wie es funktioniert

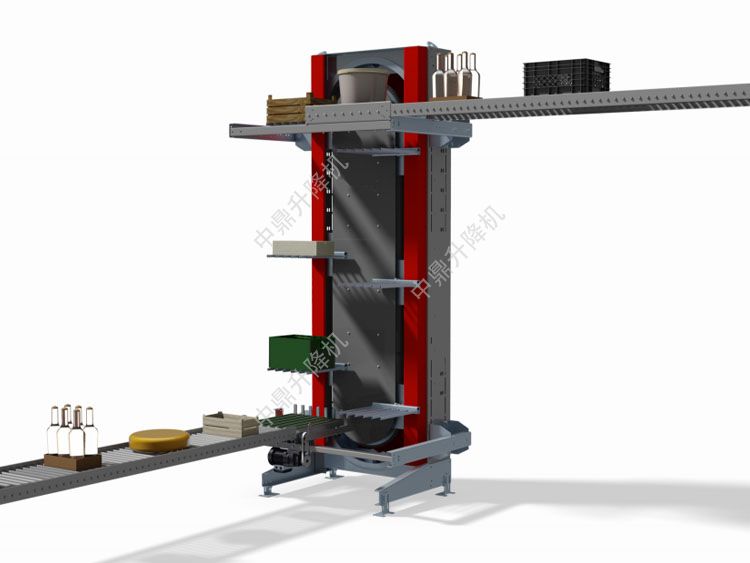

Das Gradin Hebesystem nutzt unser proprietärer riemengetriebener Mechanismus für den kontinuierlichen vertikalen Transport.

Die Materialien werden auf die Trageplattform geladen und automatisch auf die erforderliche Höhe angehoben durch Das fortschrittliche Kontrollsystem von Gradin.

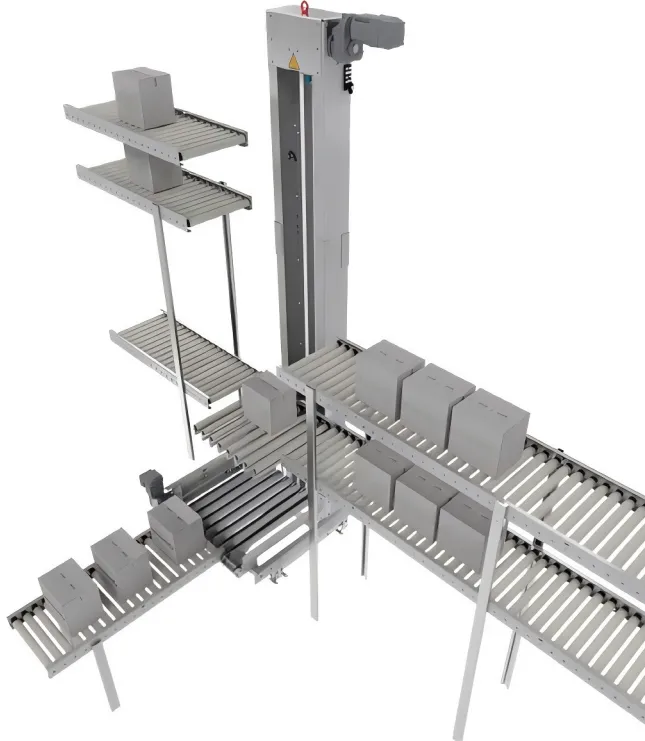

Unser modularer Aufbau unterstützt mehrere Richtungen der Aufnahme/Entlassungmit von Gradin hergestellten Rollenbahnen, die eine nahtlose Integration in bestehende Systeme gewährleisten.

Die Herausforderungen

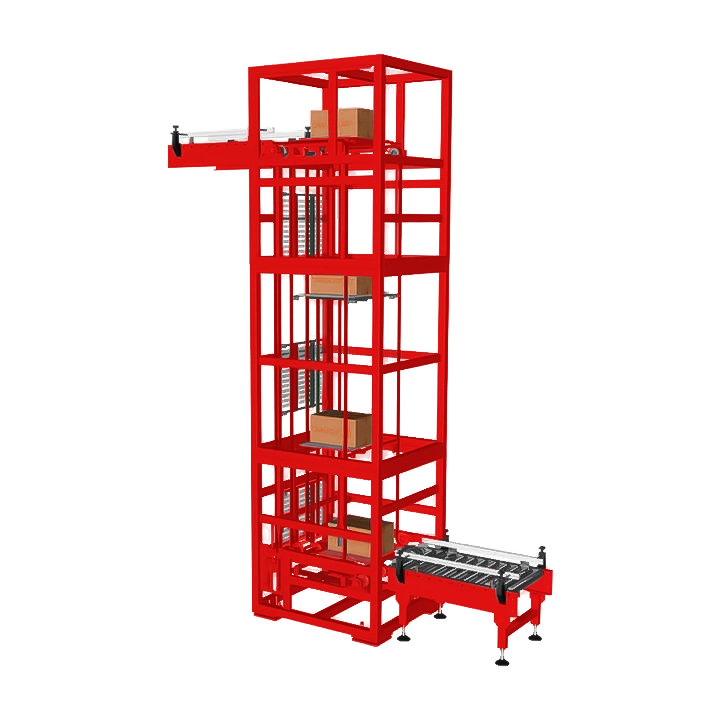

- Platzmangel, der die Installation der Geräte einschränkt

- Notwendigkeit eines kontinuierlichen vertikalen Materialtransfers

- Hoher Lärmpegel und Wartungsbedarf

- Anforderung an eine flexible Materialhandhabung

- Integrationsbedarf mit bestehenden Systemen

Lösungen

- Platzsparendes Design: Unsere kompakte Ein-Mast-Struktur

- Hoher Wirkungsgrad: 360 Zyklen/Stunde Handhabungskapazität

- Geräuscharmer Betrieb: Die exklusive Riemenantriebstechnik von Gradin

- Modulare Flexibilität: Anpassbare Richtungen und Höhen

- Nahtlose Integration: Gradin-Rollenbahnen für Systemkompatibilität

- Vielseitige Anwendung: Vielfältige Konfigurationsmöglichkeiten