6.19.2025 / 6-Minuten-Lesung

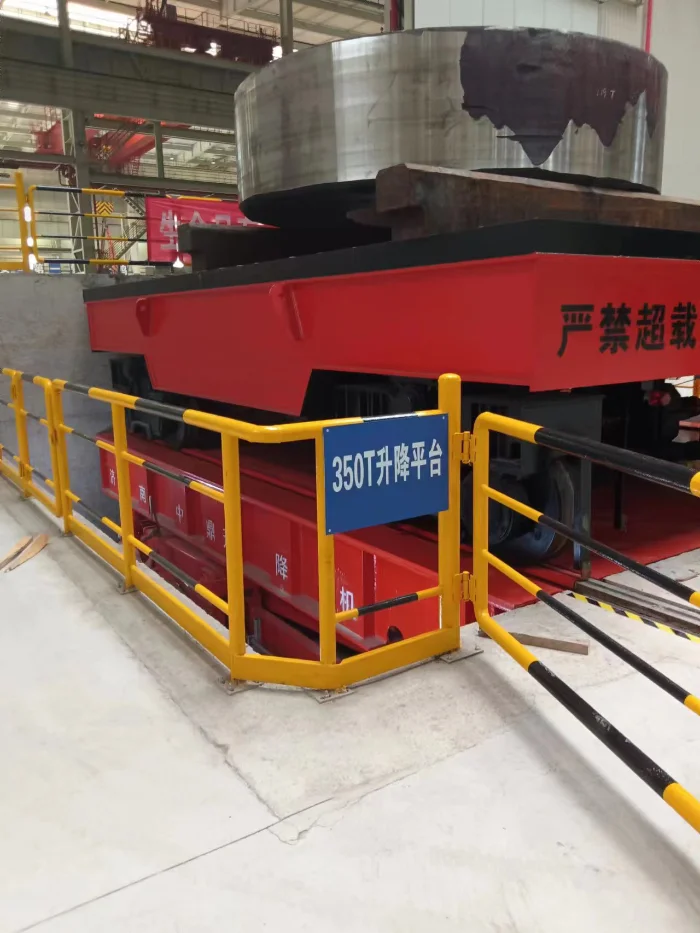

Chinas Scherenhebebühne mit maximaler Tonnage | 350T Heavy-Duty Nuclear Equipment Material Handling Solution

Überblick über das Projekt

Als Chinas Scherenarbeitsbühne mit der höchsten Tonnage ist diese 350T System überwindet die technischen Hindernisse beim Präzisionsheben mit hohen Lasten und großen Tischen.

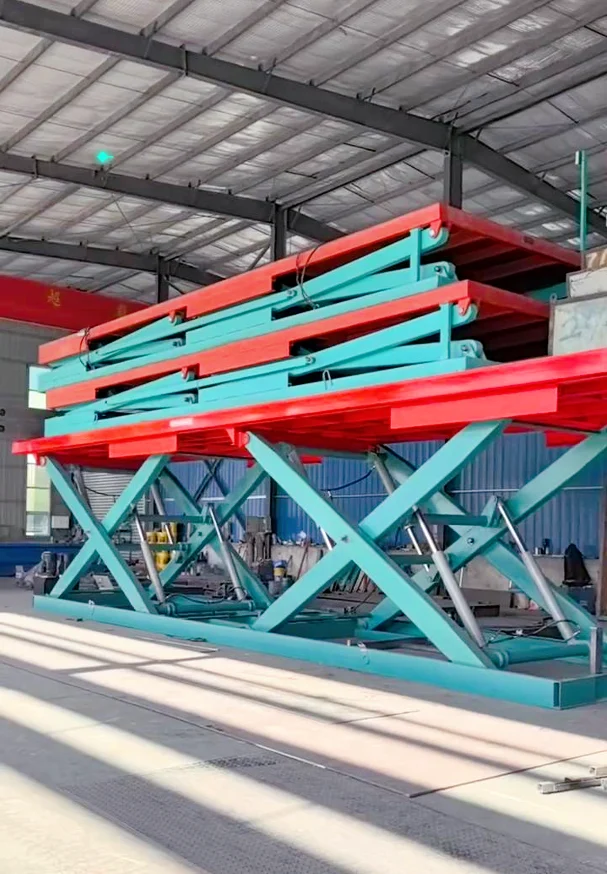

Der einlagige Doppelscherenmechanismus mit 12 synchronisierte Hydraulikzylinder erreicht eine Genauigkeit von ±1 mm.

Integriert PLC Echtzeit-Nivellierungsausgleich und Dual-Control-Modi Lösung der Probleme beim Transport mit Höhenunterschieden für Werkstätten für kerntechnische Anlagen und Schließung einer Marktlücke im Inland.

Grundlegende Parameter

| Parameter | Spezifikation | Industriestandard | Wettbewerbsvorteil |

|---|---|---|---|

| Reisegeschwindigkeit | Horizontal: 2m/s Vertikal: 0,8m/s | H: 1,5 m/s V: 0,5 m/s | 30-60% schnellere Zykluszeiten |

| Positionierungsgenauigkeit | ±2mm | ±5mm | 150% höhere Präzision |

| Tragfähigkeit | 500kg Standard (1.000kg optional) | 300kg | 67%+ größere Nutzlast |

| Betriebshöhe | Bis zu 15 m | 6-8m | Größere Kompatibilität in der Höhe |

| Kontrollmethode | Eingebautes Bedienfeld + WCS-Funk | Feste Kontrollstation | Flexible Bedienung, Fernüberwachung |

| Ausrüstung Dicke | ≤350mm | ≥500mm | 30% reduzierter Platzbedarf im Gang |

Die Herausforderung

- Ultra-schwere Last: In China gibt es keine 350-Tonnen-Scherenhebebühne, was bahnbrechende Lösungen für die strukturelle Stabilität erfordert.

- Präzise Synchronisation: Erzielung einer Synchronisation von ≤1mm über eine große Plattform von 7500×6500mm mit Mehrzylinderantrieb.

- Sicherheitskritischer Betrieb: Null-Toleranz für die Neigung der Plattform während der Übertragung von Kernkomponenten.

Lösungen

- Hydraulischer Hybridantrieb: 4 doppeltwirkende Vertikalzylinder für den Haupthub + 8 einfachwirkende Schrägzylinder für den seitlichen Kraftausgleich.

- Closed-Loop-Steuerung: Proportionales Ventilsystem mit SPS-Autokompensation auf der Grundlage von 4-Ecken-Höhenrückmeldungen in Echtzeit.

- Sicherheit Redundanz: Zwei Steuerkanäle + mechanische Positionsbegrenzung + kontinuierliche Lastüberwachung.

Vorteile

- ✓ Chinas erste: Ersetzt die importierten 350T Scherenhebebühnenlösungen.

- ✓ Sub-mm Präzision: ±1mm Synchronisation ermöglicht präzises Andocken bei hoher Last.

- ✓ Auto-Leveling: Die SPS korrigiert die Neigung der Plattform kontinuierlich über 4 Ecksensoren.

- ✓ Sicherheit auf nuklearem Niveau: Der mehrschichtige Schutz entspricht den Normen der Nuklearindustrie.

- ✓ Doppelsteuerung: Touchscreen und Fernbedienung für flexible Bedienung.