6.13.2025 / 4 Minuten gelesen

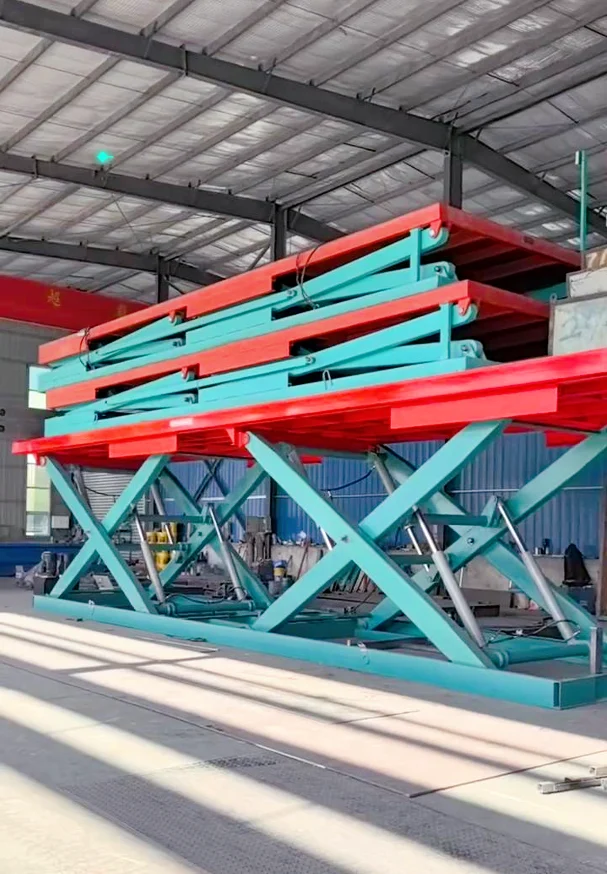

Flugzeug-Windkanal-Test-Wartungsplattform | Schwerlast-Scherenhebebühne für Triebwerkstests

Überblick über das Projekt

Diese hochbelastbare feste Scherenhebebühne wurde für die Wartung von Flugzeugtriebwerken in Windkanalprüfzellen entwickelt. Sie wird am Tunneleingang installiert und bietet den Technikern eine stabile Plattform zur präzisen Positionierung während des Triebwerksbetriebs mit voller Schubkraft.

Das System nutzt Proportionalventile für die synchrone Steuerung mehrerer Hebeeinheiten, integriert Strangpotentiometer für eine Hubrückmeldung in Echtzeit und umfasst bidirektionale Drehflügeltore aus Edelstahl mit Positionsüberwachung, um die Betriebssicherheit und die Einhaltung von Vorschriften zu gewährleisten.

Grundlegende Parameter

| Parameter | Spezifikation |

|---|---|

| Typ | Feste Schwerlast-Scherenhebebühne |

| Anmeldung | Wartung von Flugzeugtriebwerken im Windkanal |

| Steuerung der Synchronisation | Proportionalventil hydraulisch geschlossener Kreislauf |

| Rückmeldung zur Positionierung | Hochpräzise String-Potentiometer (pro Einheit) |

| Tor-System | Flügeltore aus Edelstahl in voller Breite |

| Überwachung der Sicherheit | Endschalter für die geschlossene Position des Tors |

| Tragfähigkeit | ≥10 Tonnen (typisches Motorgewicht) |

| Hebehöhe | 8-12 Meter (angepasst an die Testzelle) |

| Plattform Größe | Abdeckung über die gesamte Breite (Tunnelschnittstelle) |

| Synchronisationsgenauigkeit | ≤±2mm (dynamischer Fehler bei mehreren Zylindern) |

Die Herausforderung

- Multizylinder-Synchronisation: Millimetergenaue Synchronisierung von schwer beladenen Schereneinheiten unter dynamischer Belastung.

- Operative Stabilität: Widersteht Vibrationen und aerodynamischen Störungen bei Triebwerkstests mit voller Schubkraft.

- Sicherheitsverriegelung: Festverdrahtete Hebebühnenverriegelung zur Vermeidung gefährlicher Vorgänge.

- Long-Stroke-Positionierung: Hochpräzise Rückmeldesensoren für Verfahrwege von >10 m in rauen Umgebungen.

Lösungen

- Synchronsteuerung im geschlossenen Regelkreis

- Proportionalventile regeln den hydraulischen Durchfluss auf der Grundlage der Echtzeit-Rückmeldung von String-Potentiometern und ermöglichen eine dynamische PID-Korrektur.

- Robuste strukturelle Konstruktion

- Verstärkte Scherenarme und breiter Rahmen, um seitlichen Windlasten und Motorvibrationen standzuhalten.

- Sicherheitsverriegelungssystem

- In die SPS-Steuerung integrierte Torpositionsschalter; der Aufzugsbetrieb wird nur bei verifiziertem Schließen des Tores freigegeben.

- Industrietaugliche Sensorik

- String-Potentiometer der Schutzart IP67 sind öl-, staub- und EMI-beständig und ermöglichen eine zuverlässige Positionierung bei langen Hüben.

Vorteile

✅ Präzise Synchronisation≤±2mm Multizylinderfehler durch Regelung.

✅ Einhaltung der Sicherheitsvorschriften: Die Verriegelung des Toraufzugs erfüllt die Anforderungen der ISO 13849 SIL 2.

✅ Vollständige ökologische Widerstandsfähigkeit: Korrosionsbeständiger Edelstahl, Weittemperatur-Hydraulik (-20℃~60℃).

✅ Wartungsoptimiert: Der offene Zugang und der modulare Aufbau vereinfachen die Wartung.

✅ Rückverfolgbarkeit von Daten: Die Steuerung protokolliert die Aufzugsposition, Synchronisationsfehler und den Torstatus zur Diagnose.