9.30.2025 / 5-minute read

Lasergesteuertes 6-Tonnen-FTS | Flexibles Materialhandling für LKW-Montagewerke | Smart Logistics System

Übersicht

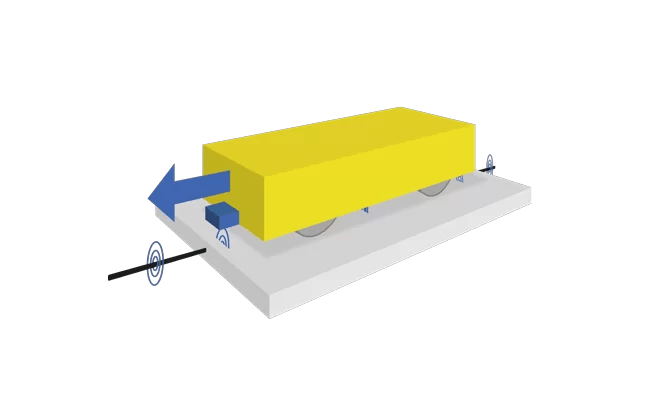

Diese 6-ton Laser-Guided AGV is engineered for modern truck assembly plants and other heavy equipment manufacturing environments.

It effectively resolves the conflict between heavy-duty material handling und flexible production lines: combining the robust strength to carry 6-ton loads with the intelligence to navigate seamlessly through complex workshops and rapidly adapt routes.

This transforms the high costs and complexity of fixed tracks into an intelligent logistics solution that delivers both high efficiency and cost-effectiveness.

Grundlegende Parameter

| Parameter | Spezifikation |

|---|---|

| Tragfähigkeit | 6 Tonnen |

| Navigation Methode | Laser navigation (supports reflector-free SLAM technology) |

| Path Flexibility | Follows predefined paths (e.g., tapes, painted lines) with adaptable routing |

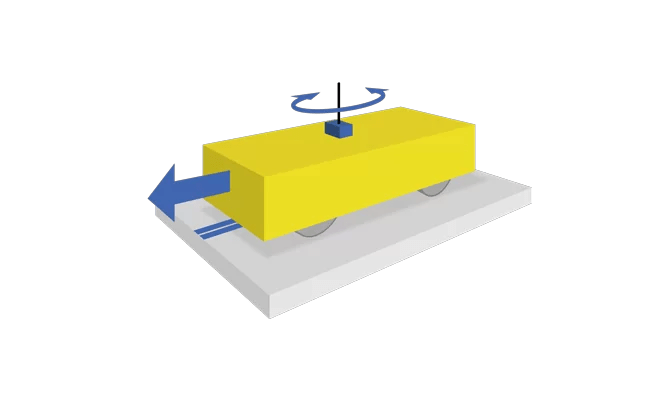

| Bewegung Leistung | Capable of high-speed operation and 360° in-place rotation |

| Communication System | 5G/Wi-Fi dual-mode network for real-time responsiveness |

| Sicherheit Schutz | 360° laser obstacle avoidance, physical bumpers, emergency stop buttons |

Eigenschaften

- Maximum Layout Flexibility

Unlike traditional RGVs constrained by fixed tracks, this AGV system enables dynamic route reconfiguration. Paths can be easily modified or expanded in software based on evolving production cycles or process optimization requirements, providing unparalleled adaptability to frequent line changes and upgrades. - Comprehensive Safety Assurance

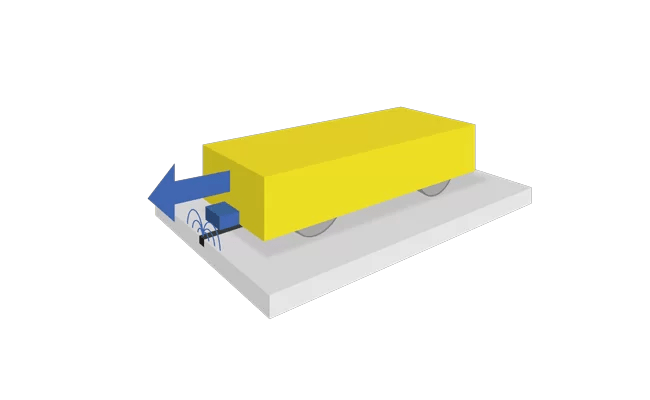

Engineered with a multi-layered safety architecture, the system ensures reliable operation. This includes 360° non-contact laser scanning for obstacle detection, physical emergency bumpers for immediate stop upon contact, and manual e-stop buttons, creating a secure environment for human-robot collaboration. - Sustained Operational Efficiency

Designed for minimal downtime, the AGV supports automatic charging or rapid battery swap systems. Integrated with a central fleet management system, multiple units perform coordinated tasks, intelligently avoiding conflicts and optimizing traffic flow to maintain continuous, high-throughput operation. - Compelling Economic Benefits

While requiring an initial investment, the AGV system eliminates the high installation and modification costs associated with fixed infrastructure like rails. It delivers a strong long-term ROI by effectively replacing multiple forklift operations, reducing labor costs, and minimizing errors through precise, 24/7 automated execution.

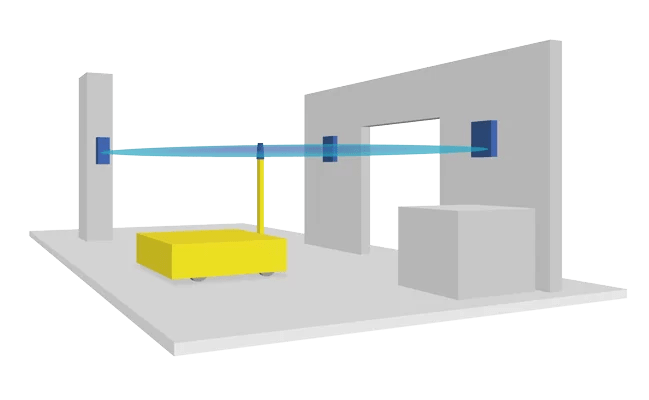

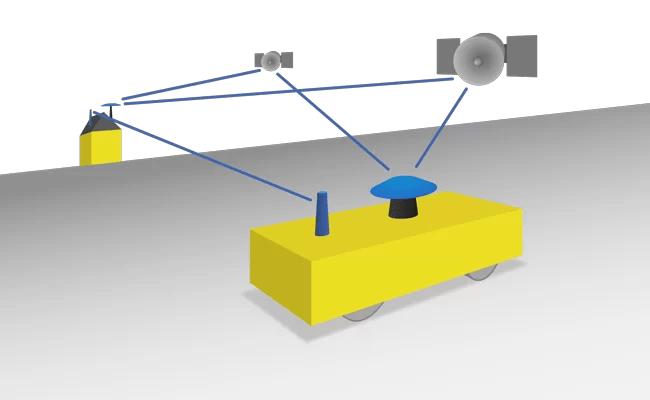

Navigationstechnik

Unsere Schwerlast-FTS zeichnen sich auf dem Weltmarkt durch ihre fortschrittlichen Lasthandhabungsfähigkeiten in Kombination mit vielseitigen Navigationsoptionen aus. Jedes Projekt wird in enger Zusammenarbeit mit dem Kunden maßgeschneidert, um sicherzustellen, dass die gewählte Führungstechnologie - oder ein hybrider Ansatz - mit den betrieblichen Anforderungen, den Umweltbedingungen und den Kostenerwägungen in Einklang steht. Es steht eine Vielzahl von Navigationssystemen zur Verfügung, die einen präzisen, sicheren und effizienten Transport von schweren und übergroßen Lasten gewährleisten.

INDUKTIVE FÜHRUNG

TRÄGHEITSFÜHRUNG

MAGNETISCHE FÜHRUNG

OPTISCHE FÜHRUNG

LASER-FÜHRUNG

dGPS-Führung

Application Scenarios & Value

In truck assembly plants, this 6-ton AGV acts as an intelligent artery connecting assembly stages. It autonomously delivers key components like heavy axles, engines, and transmissions from warehouses to precise line positions, and even participates in chassis assembly tasks.

Its value lies in integrating isolated workstations into a highly flexible, responsive smart assembly line, directly contributing to shorter lead times, lower operational costs, and improved Overall Equipment Effectiveness (OEE)—key to advancing from “traditional manufacturing” to “smart logistics”.

Für detaillierte Spezifikationen oder kundenspezifische Lösungen können Sie uns gerne kontaktieren.