9.5.2025 / 5 Minuten gelesen

Mobile 3-Achsen-Hebebühne für Spritzlackierungen

Überblick über das Projekt

Maßgeschneiderte mobile 3-Achsen-Plattform für die Lackierwerkstätten von HITACHI, die eine horizontale Bewegung von 10 m (X), eine vertikale Bewegung von 5,8 m (Y) und eine teleskopische Bewegung von 2,7 m (Z) mit einer Nutzlast von 200 kg ermöglicht.

ATEX-zertifiziert (II2G Ex db IIB T4 Gb) für explosionsgefährdete Umgebungen, installiert in 9900×9600×7850mm Kabinen (2 Einheiten/Kabine).

Grundlegende Parameter

| Produktmodell | SJG3.0-4.0 |

|---|---|

| Größe der Hebebühne | 2000*750mm |

| Platzbedarf Größe | 2100*850mm |

| Höhe des Hubs | 4000mm |

| Nennlast | 3000kg |

| Ausrüstung Eigene Höhe | 800 mm (einschließlich Radhöhe, vier Universalräder) |

| Hebegeschwindigkeit | 2-3m/min |

| Allgemeine Malerei | Gelb + Schwarz |

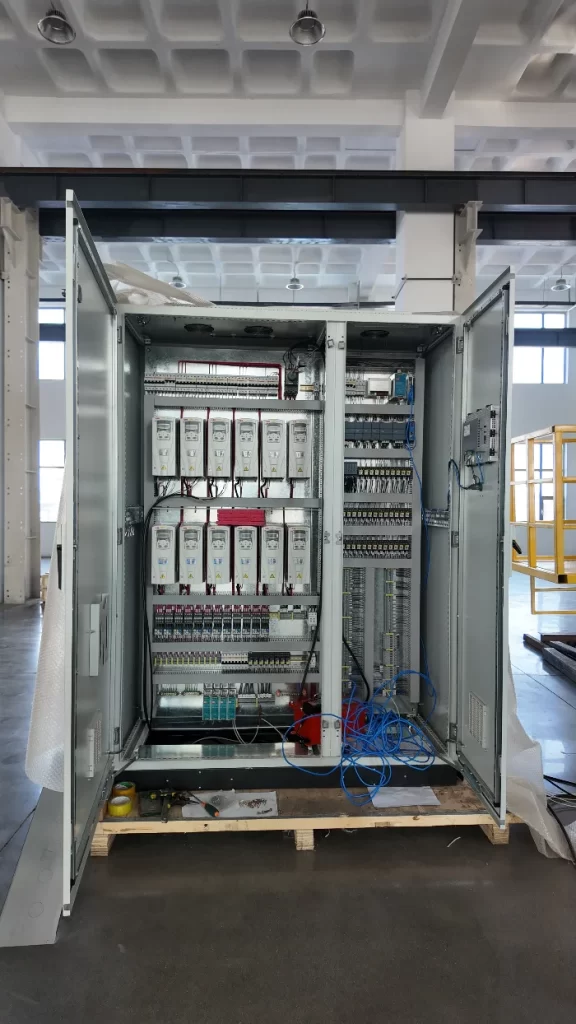

| Struktur | Zwei Scherengabeln + Synchronmotor + hydraulische Pumpstation + Steuerung |

| Struktur der Scherengabel | Einfeldig, dreilagig |

Die Herausforderung

- Z-Achse Stabilität: 4,3m Teleskophub mit 200kg Last Risiken Scherenarmauslenkung.

- Kosten und Vorlaufzeit: Hoher Preis/Lieferumfang von ABB Ex-Bremsen, die alternative Lösungen erfordern.

- Kabelmanagement: Großer Schleppketten-Biegeradius (≥200mm) für Multi-Kabel-Schutz.

- Platzbeschränkungen: Eine dichte Geräteanordnung erfordert ein kompaktes Schienen-/Trägerdesign.

Lösungen

- Verstärkung der Z-Achse: Arme aus Manganstahl und Kreuzrollenführungen erhöhen die Steifigkeit; Doppelmotoren mit Encodern begrenzen die Durchbiegung auf 8,6 mm.

- Elektromagnetische Bremse: ATEX-zertifizierte Bremsen (200N-m Drehmoment) senken die Kosten um 40% und die Vorlaufzeit um 50%.

- Geschichtete Schleppketten: Getrennte Strom-/Signalkabel in Ketten mit 180 mm Biegeradius für 500k Zyklen.

- Modulare Schiene: Vormontierte Schnellwechselschienen + eingebettete Stützen sparen 15% Platz.

Vorteile

✅ Volle Ex-Sicherheit: 12 ATEX-zertifizierte Motoren/Schalter für IIB T4-Zonen.

✅ Schwere und große Reichweite: Z-Achse 4,3m/200kg mit <0,2% Durchbiegung.

✅ Hohe Flexibilität: Geschwindigkeitsregelung von 0-12m/min, 95% Reichweite pro Einheit.

✅ Einfache Wartung: Mehrschichtige Ketten und modulare Raupen verkürzen die Ausfallzeiten um 50%.

Kostengünstig: 30% Einsparungen bei alternativen Bremsen, 8-wöchige Lieferzeit.