9.17.2025 / 5-Minuten-Lesung

Hochpräzise mechanische Hebebühne für die Luft- und Raumfahrt zur Wartung von Flugzeugtriebwerken und für Windkanaltests

Übersicht

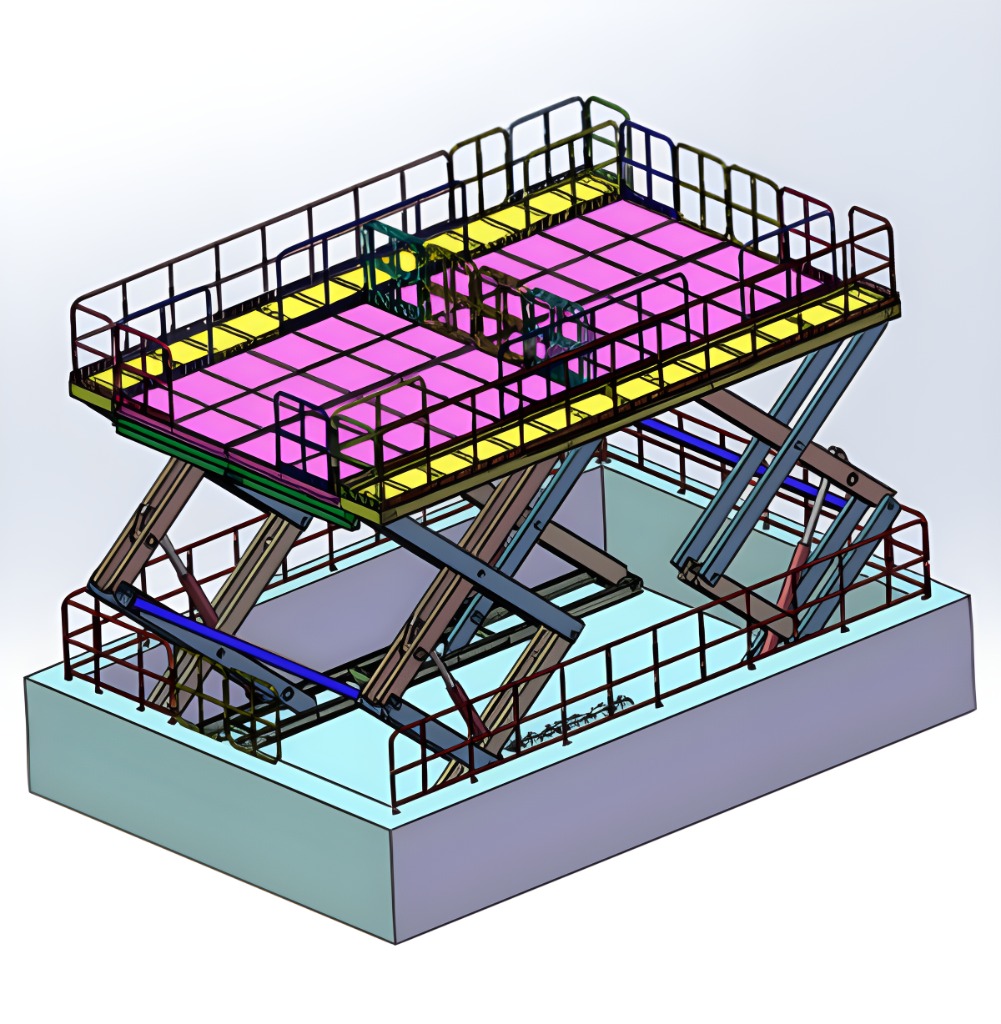

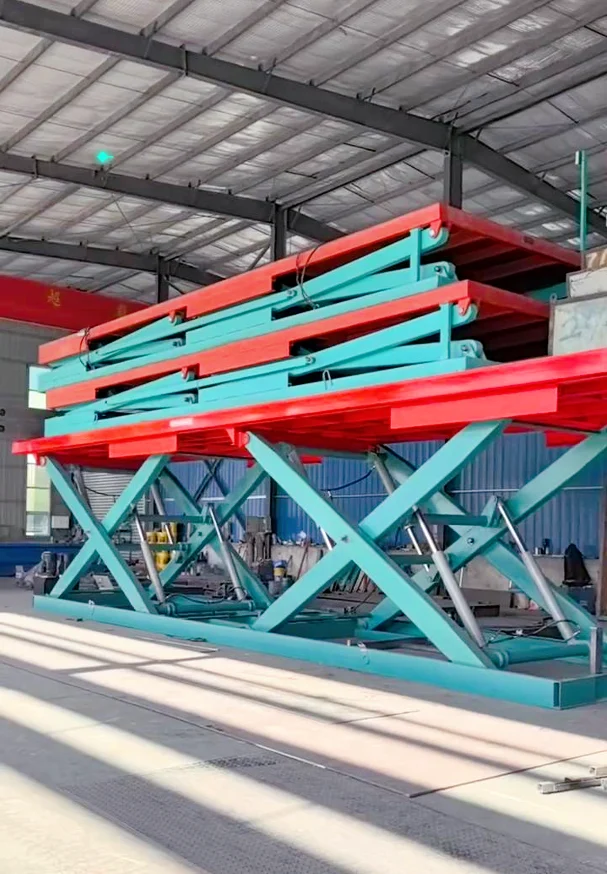

Diese Fallanalyse beschreibt eine hochpräzise mechanische Hebebühne die speziell für die Anforderungen der Luft- und Raumfahrtindustrie entwickelt wurden.

Er wurde für die Hersteller von Flugzeugtriebwerken und die Wartung von Flugzeugen entwickelt und erreicht durch fortschrittliche mechanische Strukturen und Steuersysteme millimetergenaues Heben, wodurch die extremen Anforderungen an Sicherheit und Genauigkeit in der Luft- und Raumfahrt erfüllt werden.

Grundlegende Parameter

| Parameter | Technische Spezifikation |

|---|---|

| Positionierungsgenauigkeit | ±0,5 mm |

| Hebegeschwindigkeit | 0,1-5m/min (stufenlos einstellbar) |

| Ebenheit der Plattform | ≤1mm/m² |

| Schutzart | IP65 (staub- und wasserdicht) |

| Kontrollsystem | Mehrachsige synchrone Servosteuerung |

| Sicherheitseinrichtungen | Doppelte redundante Sicherheitsverriegelung + Absturzsicherung |

| Material Standard | Aluminium/Edelstahl in Luft- und Raumfahrtqualität |

| Temperaturbereich | -20℃ bis +50℃ Betriebsbereich |

Wie es funktioniert

Das Gerät arbeitet mit präzisen mechanischen Übertragungssystemen und fortschrittlicher Servosteuerungstechnik, die durch die mehrachsige Synchronsteuerung präzise und gleichmäßige Bewegungen der Plattform ermöglicht.

Ausgestattet mit Plattformaufstiegen, Sicherheitsgurtanschlüssen und abnehmbaren Handläufen, steuern die Bediener den Hebevorgang über eine benutzerfreundliche Schnittstelle, während das System den Last- und Positionsstatus in Echtzeit überwacht und so absolute Sicherheit bei kritischen Vorgängen gewährleistet.

Die Herausforderungen

Der Luft- und Raumfahrtsektor steht bei der Wartung und Herstellung von Ausrüstungen vor einzigartigen Herausforderungen:

- Die Wartung von Flugzeugtriebwerken und kritischen Komponenten erfordert eine millimetergenaue Positionierung.

- Extreme Stabilität und Zuverlässigkeit der Geräte sind für spezielle Umgebungen wie Windkanaltests unerlässlich.

- Strenge Sicherheitsstandards erfordern mehrere, redundante Sicherheitsmechanismen.

- Unterschiedliche Flugzeugtypen und Einsatzszenarien erfordern sehr individuelle Lösungen.

- Die Geräte müssen unter den einzigartigen Umgebungsbedingungen der Luft- und Raumfahrt zuverlässig funktionieren.

Lösungen

- Ultimative Präzisionskontrolle: Ein Mehrachsen-Synchronservosystem gewährleistet eine Positioniergenauigkeit von ±0,5 mm.

- Umfassende Sicherheit: Zweifach redundante Sicherheitssysteme, Absturzsicherungen und integrierte Sicherheitsverbindungspunkte sorgen für mehrschichtige Sicherheit.

- Hohe Anpassungsfähigkeit: Das Design unterstützt verschiedene Konfigurationen, einschließlich U-Scherenplattformen, um verschiedene Flugzeugmodelle aufzunehmen.

- Materialien für die Luft- und Raumfahrt: Für die Konstruktion werden Aluminium und Edelstahl aus der Luft- und Raumfahrtindustrie verwendet, um eine optimale Kombination aus Leichtigkeit und Haltbarkeit zu erreichen.

- Intelligentes Kontrollsystem: Eine benutzerfreundliche Schnittstelle rationalisiert die Abläufe und verbessert die Effizienz des Arbeitsablaufs.

- Widerstandsfähigkeit der Umwelt: Ein breiter Betriebstemperaturbereich gewährleistet die Leistung in verschiedenen Luft- und Raumfahrtumgebungen.