29.4.2025 / 5 Minuten gelesen

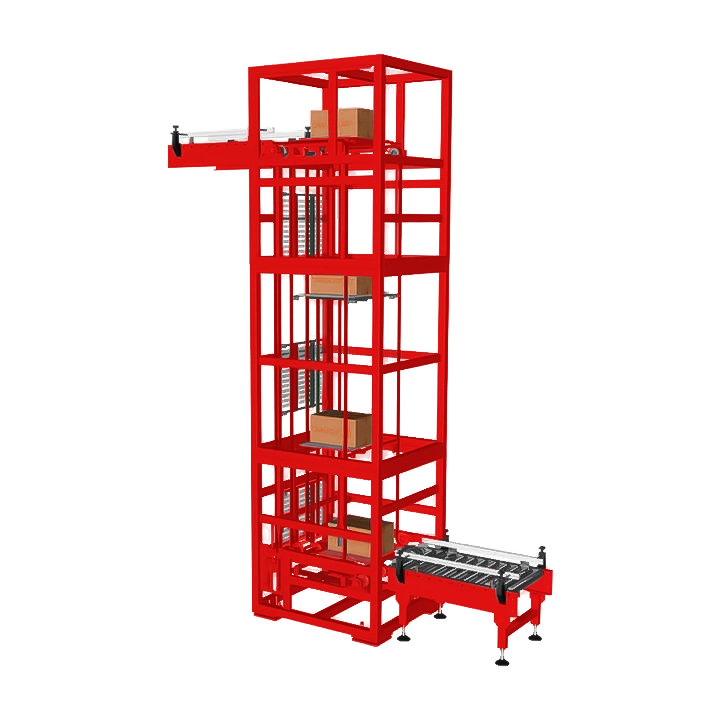

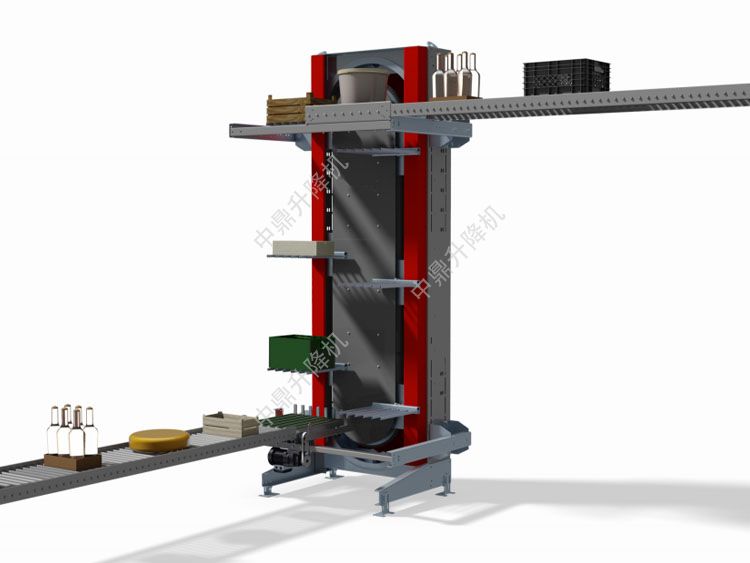

Kontinuierliches vertikales Liftsystem für die Handhabung von Kartons in mehrstöckigen Lagern

Überblick über das Projekt

Kunde: Regionales Logistikzentrum mit Spezialisierung auf E-Commerce-Fulfillment

Standort: Städtisches Lager mit begrenztem Platzangebot

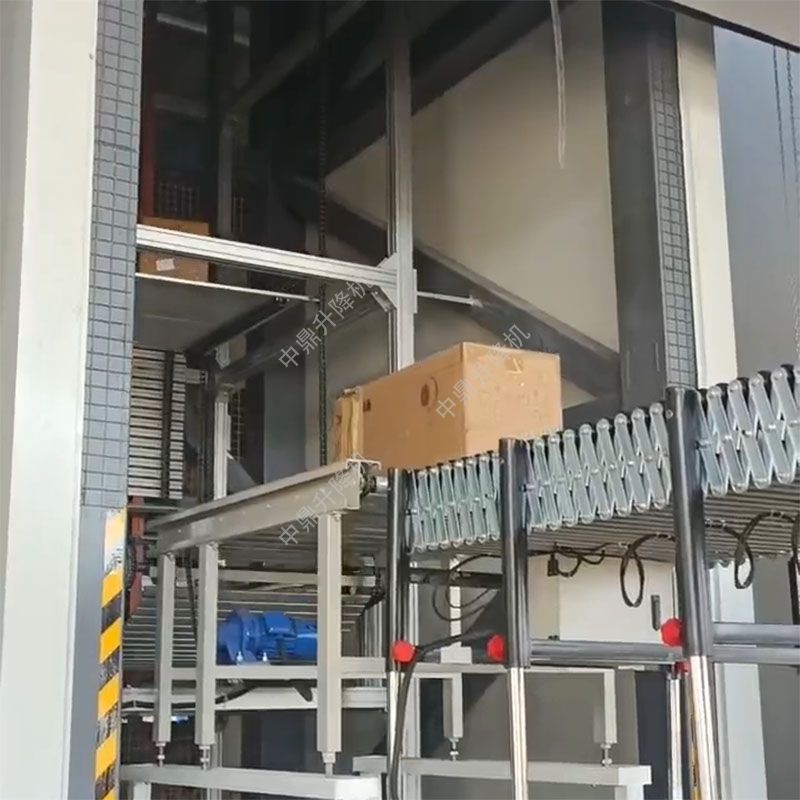

Zielsetzung: Einsatz eines kontinuierlichen Vertikalliftsystems zur Automatisierung des Transports von Kartons zwischen dem 1. und 2. Stockwerk, das in die bestehenden Förderlinien für große Mengen von Kartons mit unterschiedlichen Abmessungen integriert wird.

Grundlegende Parameter -

| Parameter | Spezifikation |

|---|---|

| Hubhöhe | 7 Meter (vom Boden bis zum Fußboden) |

| Breite des Förderbandes | 1,2 Meter (synchronisiert mit bestehenden Gurtsystemen) |

| Tragfähigkeit | 30-50 Kartons/Minute (variable Größen: 200-800 mm³) |

| Antriebssystem | Zweiketten-Dauerschleife mit servogesteuerter Geschwindigkeit |

| Sicherheitsmerkmale | Photoelektrische Sensoren, Not-Aus, Überlastalarm |

| Stromversorgung | 380V/50Hz (3-Phasen) mit Pufferbatterie für Ausfallzeiten |

Die Herausforderung

- Platzbeschränkungen: Ein enges Lagerlayout erforderte eine kompakte vertikale Lösung, ohne die Arbeitsabläufe zu stören.

- Variabilität des Kartons: Handhabung unregelmäßiger Kartongrößen (200-800 mm³) ohne Stau oder Ausrichtungsfehler.

- Nahtlose Integration: Synchronisierung der Geschwindigkeit/Position des Aufzugs mit vor- und nachgelagerten Förderern (1,2 m Breite).

- Anforderungen an die Effizienz: Erzielung eines Durchsatzes von 50+ Kartons/Minute während der Spitzenzeiten.

- Dauerhaftigkeit: Minimierung der Wartungsausfallzeiten in einer 24/7-Betriebsumgebung.

Lösungen

- Modulare vertikale Aufzugskonstruktion:

- Kontinuierliche, kettengetriebene Plattform: Doppelkettenschlaufen mit 10 Ladebuchten für eine ununterbrochene Auf- und Abwärtsbewegung.

- Dynamische Breitenanpassung: Die Seitenschutzschienen passen sich automatisch (500-1.200 mm) an die Kartongrößen an.

- Intelligente Förderer-Integration:

- RFID-Scanning-Gates: Vorab-Scannen der Kartons an den Eingangs-/Ausgangspunkten, um sie in die entsprechenden Etagen zu leiten.

- Speed-Matching-Algorithmus: Servomotoren synchronisieren die Geschwindigkeiten von Aufzug und Förderer (Genauigkeit ±0,1s).

- Verbesserungen der Zuverlässigkeit:

- Selbstschmierende Ketten: Geringerer Verschleiß bei 24/7-Betrieb.

- Staubgeschützte Gehäuse: Entscheidend für Lagerumgebungen mit Papierabfällen.

- Sicherheit und Überwachung:

- 3D-LiDAR-Sensoren: Erkennen Sie überstehende Kartons oder Fehlladungen und lösen Sie den automatischen Stopp aus.

- Warnmeldungen zur vorausschauenden Wartung: IoT-fähige Schwingungs-/Temperaturüberwachung.

Vorteile

- Durchsatzsteigerung: Kapazität von 50 Kartons/Minute, wodurch Engpässe beim manuellen Heben beseitigt werden.

- Optimierung der Raumfahrt: Vertikaler Platzbedarf <4m² im Vergleich zu herkömmlichen Schrägförderern.

- Anpassungsfähigkeit: Fasst 200-800 mm³ Kartons ohne manuelle Einstellungen.

- Energie-Effizienz: Regeneratives Bremsen reduziert den Stromverbrauch um 20%.

- Skalierbarkeit: Die modulare Bauweise ermöglicht eine spätere Erweiterung bis zur Integration des 3.