12.10.2025 / 5-minute read

Wind Farm Personnel Hoist Solutions | Rack and Pinion Elevators

Overview

The global trend towards taller towers and larger-capacity wind turbines, especially in offshore environments, has intensified the challenge of safe personnel and tool access. Traditional methods, such as rope-climbing or wire-rope guided hoists, present significant safety and efficiency limitations.

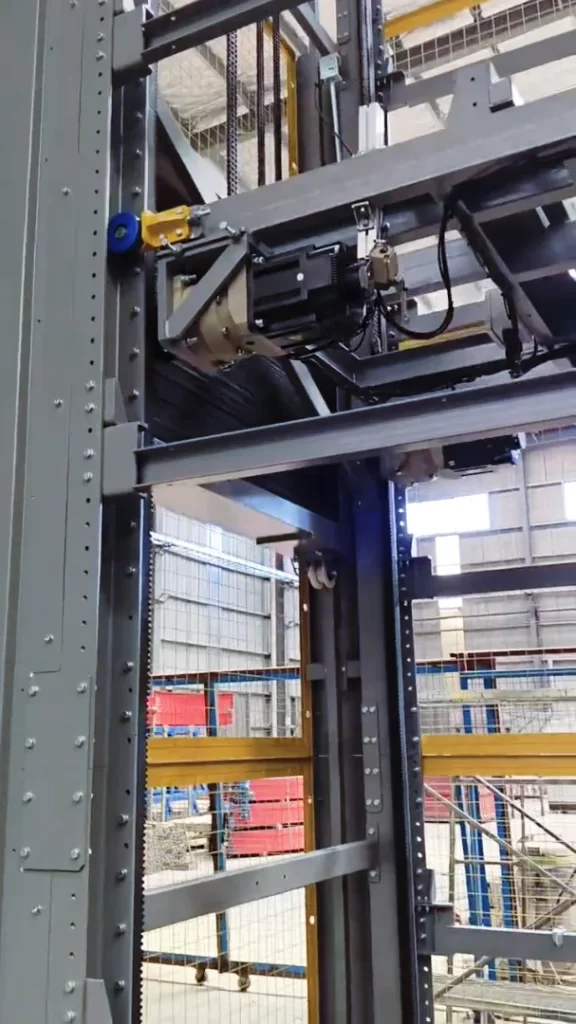

The rack and pinion hoist offers a engineered solution. Unlike traditional systems, it employs a gear meshing directly with a fixed rack installed on the tower wall. This design is fundamentally safer and more robust, making it the preferred choice for modern wind farms.

Illustrative Project: Jiangsu Guoxin Dafeng Offshore Wind Farm

Basic Parameters

| Feature Comparison | Rack and Pinion Hoist | Traditional Wire Rope Hoist |

|---|---|---|

| Core Mechanism & Safety | Positive gear engagement, inherently safe | Relies on friction/traction, cable failure risk |

| Installation & Timeline | Can be installed alongside tower sections, immediate use | Requires complete tower first, creates access gap |

| Reliability & Maintenance | Dual motor, sliding power supply, high reliability, low maintenance | Single-point failure risk, cable wear/entanglement issues |

| Operational Efficiency | Higher load & speed, efficient crew & tool transport | Limited capacity, slower, impacts scheduling |

Application in Wind Industry

- Construction Phase Acceleration: As demonstrated in the Jiangsu Dafeng and Gansu Jingyuan projects, the ability to provide access immediately after each tower section is lifted is a key productivity driver, solving the “construction access gap”.

- Long-Term Operation & Maintenance (O&M): The Shanghai Lingang Offshore Project serves as a testament to long-term reliability, where 25 units have operated safely for over six years. This durability is critical for minimizing downtime over a turbine’s 20+ year lifespan.

- Adapting to New Tower Designs: The technology has been successfully integrated into split-section towers, a newer design for easier transport. Projects like the A’rongqi wind farm in Inner Mongolia use a combined “hoist + climber” solution to navigate this complex internal structure.

- Extreme Environments: Rack and pinion hoists support projects in extreme conditions, such as the world’s highest-altitude wind farm in Tibet (5,300m), proving their resilience and reliability.

Results

- Safety Transformation: Replaces hazardous ladder climbing during construction and provides a stable, fail-safe transport system, directly reducing fall risks.

- Efficiency Gains: Cuts turbine construction time by enabling concurrent access work. Faster transit speeds (36 m/min vs. 18 m/min) also reduce daily maintenance travel time.

- Reduced Lifetime Costs: Enhanced reliability and redundant systems lower the risk of costly breakdowns and crane-dependent rescues. The ability to transport tools inside the cabin also saves on separate equipment lifts.

- Industry Validation: The technology’s adoption by major developers and its use in landmark national projects (e.g., “Ludian into Shandong” initiative) underscore its status as an industry-best-practice solution.