10.29.2025 / 5-minute read

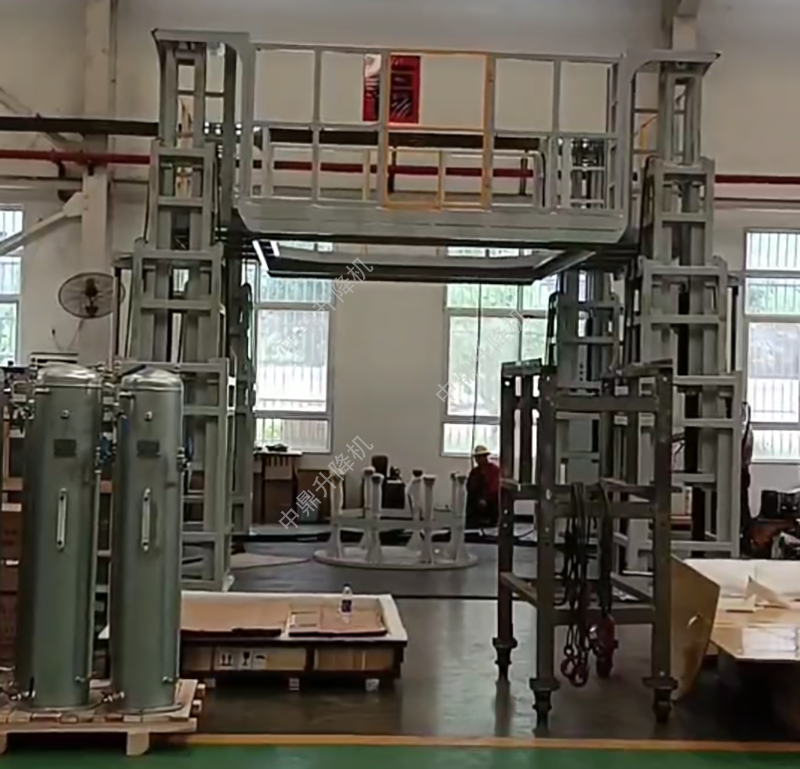

Transformer Core Stacking & Turning Platform | Large Transformer Core Process Equipment

Overview

This transformer core stacking and turning platform represents a heavy-duty specialized tooling system specifically engineered for large and medium-sized transformer core manufacturing processes.

Featuring an innovative modular structure and mechanical turning technology, it effectively addresses three core challenges in transformer core stacking and turning: precision control, safety stability, and process adaptability.

The system eliminates the need for traditional pit foundations, requiring only a ground positioning slot for rapid deployment. While ensuring deformation-free core turning, it significantly reduces equipment investment and space requirements, making it an ideal solution for modern transformer production.

Basic Parameters

| Parameter | Specification |

|---|---|

| Load Capacity Series | 35T, 60T, 80T, 100T, 130T, 180T, 250T |

| Core Functions | Core Stacking, 90° Turning |

| Structure Type | Modular Building-Block Structure |

| Platform Deformation | < 3mm during turning |

| Positioning Accuracy | Verticality change < 2mm |

| Installation Requirements | No pit needed, only ground positioning slot |

| Power Source | Utilizes existing workshop crane, no external power |

Core System Components

- Turning Platform Main Body: I-beam platform, gear-shaped turning beam, turning seat, positioning square beam forming the main load-bearing frame

- Support & Stabilization System: Legs, pin shafts, leveling jacks ensuring operational stability

- Process Auxiliary System: I-beam supports, horizontal supports, quick clamps and other iron arrangement accessories

- Lifting System: Specialized lifting beam and support, compatible with workshop cranes

Operational Workflow

- Core Stacking Phase: Rapid platform assembly based on core window dimensions using modular structure, completing precise silicon steel sheet stacking in horizontal position

- Process Preparation: Installation of iron arrangement positioning devices, using strap tensioning devices for core binding

- Safe Turning Phase: Utilizing workshop crane as power source, achieving smooth 90° core turning through precise engagement of gear-shaped turning beam and seat

- Safety Protection: Immediate leg deployment after turning to prevent accidental core tipping

The Challenges

- Specification Diversity: Varying core window sizes across transformer models challenge traditional fixed equipment

- Extreme Precision Requirements: Minimal gaps between core laminations mean any deformation during turning affects transformer performance

- Space Constraints: Traditional turning equipment requires deep pits and special foundations with high modification costs

- Process Complexity: Advanced processes like non-removable upper yoke place higher demands on tooling equipment

- Safety Risks: Critical stability control during heavy core (up to 250 tons) turning operations

Solutions

Innovative Modular Design

- Building-Block Structure: Flexible assembly according to core window dimensions, perfectly adapting to different core structures

- Adjustable Center Distance: Customizable platform sizes break traditional equipment limitations

Exceptional Economy & Adaptability

- Pit-Free Installation: Only requires ground positioning slot, significantly reducing infrastructure cost and time

- Zero Energy Consumption: Smart utilization of existing workshop cranes as power source

- High Cost-Effectiveness: Reduced auxiliary equipment investment with short payback period

Advanced Process Support Capabilities

- Full Process Compatibility: Perfectly supports both removable and non-removable upper yoke processes

- Process Optimization: Modular structure facilitates installation of iron arrangement devices, improving efficiency

- Binding Innovation: Enables strap tensioning device use in horizontal position, eliminating need for auxiliary clamps

Precision Engineering & Manufacturing

- Finite Element Analysis: Advanced international software for reliability verification

- Precision Manufacturing: Machined critical positions, aged welded structures ensuring flatness

- Accuracy Assurance: Stringent standards of <3mm deformation and <2mm verticality change