10.17.2025 / 5-minute read

Manual Guided Omni-Directional Transport Vehicle for Heavy-Duty Rail Industry

Overview

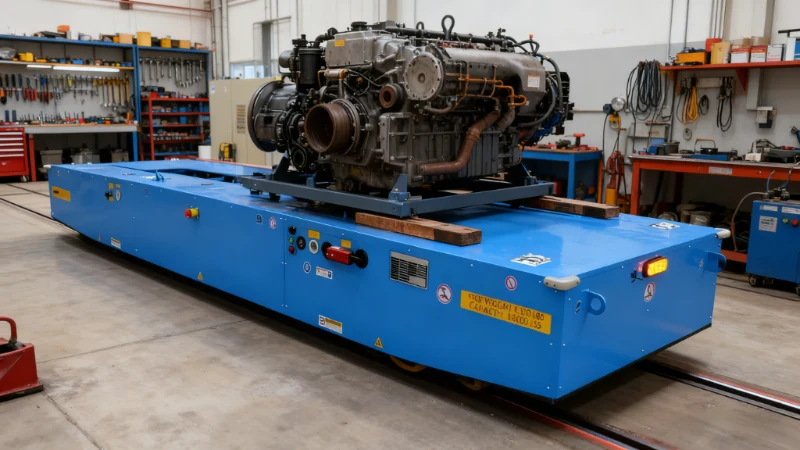

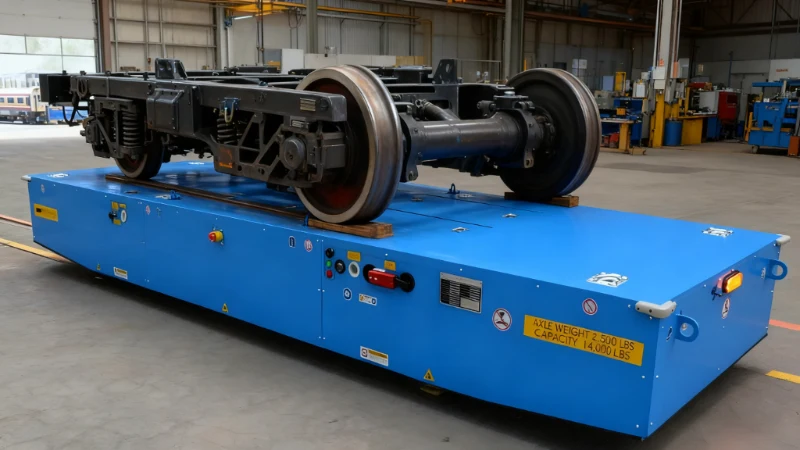

The Manual Guided Omni-Directional Transport Vehicle is a specialized heavy-duty load carrier engineered to meet the demanding material handling needs of the railway industry.

It features a robust welded frame structure, a high load capacity of up to 6 tons, and unique omnidirectional movement capabilities.

This vehicle is designed for efficient transportation and positioning of heavy machinery, equipment, and components within maintenance depots, manufacturing facilities, and assembly lines.

Its compact and flexible design makes it indispensable for operations in confined and complex environments.

Basic Parameters

| Parameter | Specification |

|---|---|

| Max Load Capacity | 6 Tons (Customizable) |

| Drive Technology | Mecanum Wheel (Omnidirectional) |

| Turning Radius | Zero |

| Control Mode | Wireless Hand-Held Remote |

| Frame Construction | High-Strength Steel |

| Typical Applications | Railway Workshops, Assembly Lines, Maintenance Depots |

Key Applications in the Railway Industry

This versatile vehicle is ideal for various heavy-load scenarios in the rail sector:

- Transporter for Bogies, Engines, and Train Components

- Positioning and Assembly of Carriage Interiors

- Maintenance and Repair Tasks in Depot Facilities

- Feeding Production Lines with heavy sub-assemblies

Advantages

Each wheel is independently driven and fitted with a series of rollers oriented at a 45-degree angle. This allows the vehicle to perform:

- Forward and Backward Movement

- Sideways Drifting (Crab Movement)

- Zero-radius Rotation (pivoting on its own axis)

- Diagonal and Curved Paths without the need for a steering mechanism

This zero-turning radius capability ensures unparalleled maneuverability, enabling the vehicle to navigate tight alleyways and crowded workshop floors with precision.

Built for the toughest industrial environments, its durability is defined by:

- High-Strength Frame: The main structure is fabricated from robust structural steel and plates, capable of supporting loads up to 6 tons.

- Precision Engineering: Critical surfaces are machined to ensure flatness and alignment, guaranteeing stability under full load.

- Durable Finish: A sandblasting and anti-rust painting process protects the vehicle from corrosion, ensuring long-term reliability and a professional appearance.

Traditional wired control is replaced with an advanced hand-held remote control system. This offers:

- Enhanced Operational Freedom: Operators can guide the vehicle from the most convenient and safe vantage point.

- Intuitive Control: The ergonomic remote features a clear layout for movement direction, speed adjustment, and emergency functions.

- Flexible Deployment: The wireless system allows for quick deployment without the constraints and trip hazards of cables .

Cases for Transportation

No posts