12.1.2025 / 6-minute read

Intelligent Buffering and Vertical Conveying Hub between Flexible Production Lines and High-Bay Warehousing

Project Overview

A leading global beverage manufacturer at its flagship plant operated multiple high-speed filling lines producing products in various bottle types and pack formats (e.g., multi-packs of 500ml PET bottles, 330ml cans).

At the end of each line, filled product cases (or shrink-wrapped trays) needed to be conveyed to the palletizing area before being transferred to the automated storage and retrieval system (AS/RS).

The traditional setup involved dedicated lift conveyors for each line, elevating cases to the palletizer working height. This led to equipment redundancy, inflexible layout, and underutilization of palletizers when line speeds varied or experienced brief stoppages, creating a production bottleneck.

The plant required an intelligent conveying solution that could consolidate multi-line flow, balance production cadence, and provide buffering functionality.

Basic Parameters

| Parameter Category | Key Specifications |

|---|---|

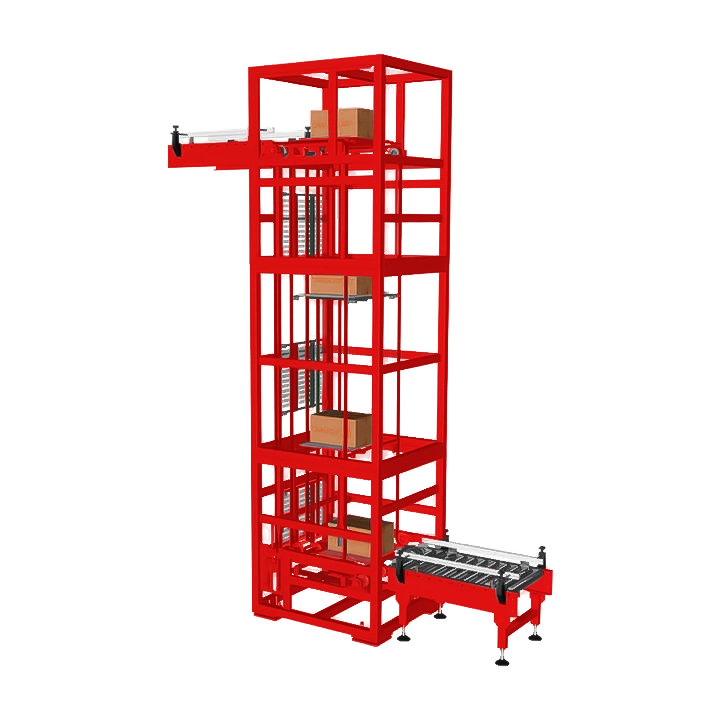

| System Configuration | • Type: Z-Type, Continuous Vertical Conveyor • Function: Multi-Line Merging, Vertical Transport & Sorting • Infeed Points: 4 (Ground Level) • Discharge Points: 3 (Elevated, +3.5m) |

| Mechanical & Performance | • Carrier Units: 80+ Independent Trays • Max. Payload per Tray: 75 kg • Vertical Speed: 1.2 m/s • System Throughput: > 2,000 cases/hour |

| Control & Integration | • Core Control: PLC with SCADA HMI • Integration: Plant MES • Identification: Barcode Scanning at Infeed |

| Key Performance Outcomes | • Palletizer Utilization: > 95% • Conveyance Time Reduction: 22% • Floor Space Saved: ~35% • ROI Period: 28 months |

Challenge

- Multi-Line Merging & Flow Balancing: Simultaneously receiving cases from 3-4 filling lines operating at potentially different speeds (e.g., 500 bpm, 800 bpm) and merging them seamlessly without congestion.

- Continuous Supply & Buffering: Providing an uninterrupted, on-demand material flow to 2-3 downstream high-speed palletizing robots, with the ability to absorb minor fluctuations or short stops from upstream lines.

- Space Optimization & Layout Flexibility: Replacing multiple dispersed lifts to reduce floor space footprint and adapt to future line reconfiguration or expansion.

- Zero Product Damage & High Hygiene Standards: Ensuring smooth, quiet conveyance with equipment design complying with food & beverage industry hygiene requirements (easy to clean, no sanitation dead zones).

Workflow

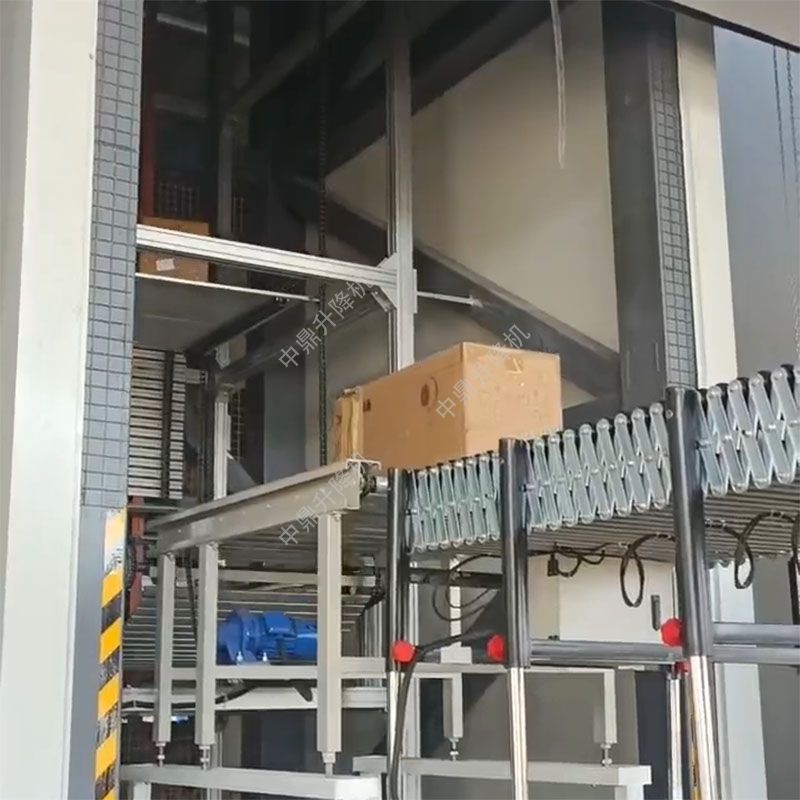

- Identification & Induction: Cases from production lines are scanned at the infeed. The PLC assigns a target palletizing workstation (based on production order or load-balancing logic) and inducts the case onto an empty tray.

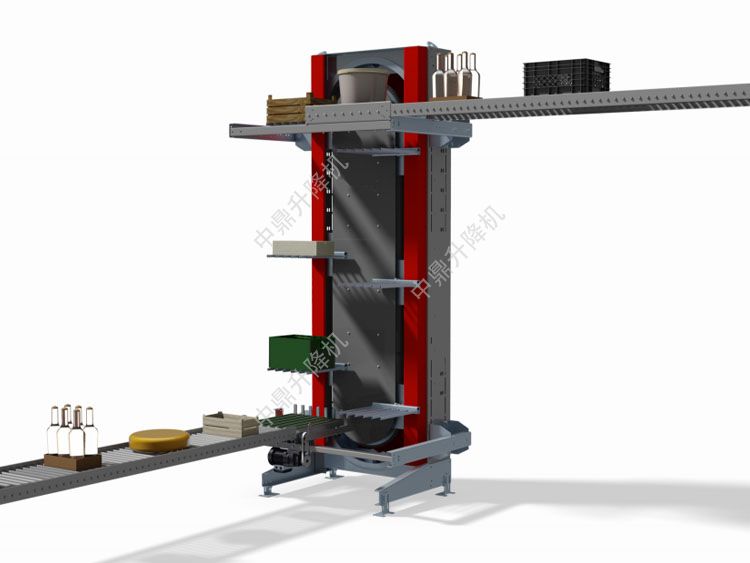

- Vertical Conveying & Dynamic Routing: Loaded trays enter the continuously moving vertical loop. The system pre-determines the tray’s path based on its assigned destination.

- Precise Diverting & Discharge: Upon reaching the level of the target discharge point, an active transfer device quietly and smoothly guides the tray onto the horizontal conveyor leading to the assigned palletizer. A sensor confirms discharge, and the empty tray continues its cycle.

- Intelligent Buffering & Sequencing: If a palletizer is temporarily stopped (e.g., for slip sheet changeover or minor maintenance), the PLC can dynamically “store” cases destined for that station on circulating trays or re-route them to other available palletizers, ensuring upstream production lines never stop due to downstream blockage.

Solution

- Maximized Equipment Utilization & Output: Consolidating multiple flows into a single high-efficiency system eliminated waiting and imbalance between individual machines, increasing palletizer utilization to over 95%.

- Built-In Production Resilience: The circulating path acts as a dynamic buffer, capable of absorbing several minutes of production fluctuation, providing a critical time window for upstream interventions.

- Significant Footprint Reduction: The system saved approximately 35% of floor space compared to the footprint required by four independent lifts and complex ground-level merging conveyors.

- High Reliability & Maintainability: Modular design and continuous operation reduce start-stop shock. Key components (e.g., drive units) are easily accessible for maintenance, leading to a substantially improved Mean Time Between Failures (MTBF).

- Future-Proof Scalability: The number of infeed/discharge points and routing logic can be reconfigured via software, allowing easy adaptation to future line additions or process changes.