12.2.2025 / 5-minute read

Enhancing Operational Efficiency and Safety in a Luxury Urban Hotel

Project Overview

A prominent urban luxury hotel operates in a high-demand environment characterized by continuous high occupancy rates.

Like many in the hospitality industry, its back-of-house logistics are complex and critical to seamless guest service.

These operations involve the constant vertical movement of diverse goods, including daily food deliveries, fresh linens, maintenance supplies, and event materials.

The efficiency of this internal supply chain directly impacts kitchen readiness, room turnover speed, and overall operational fluidity.

Basic Parameters

| Category | Parameter | Specification |

|---|---|---|

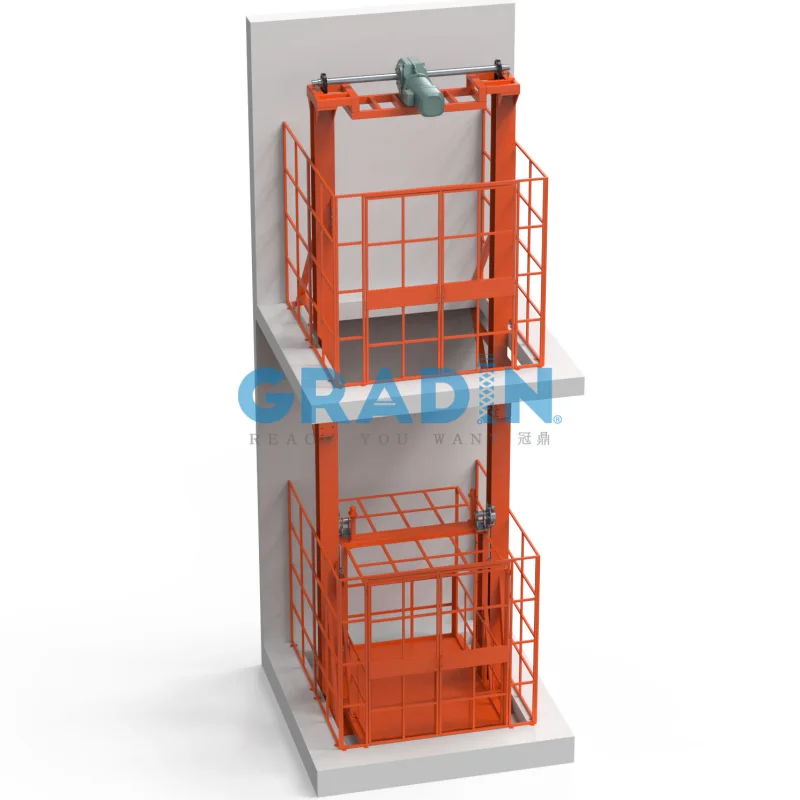

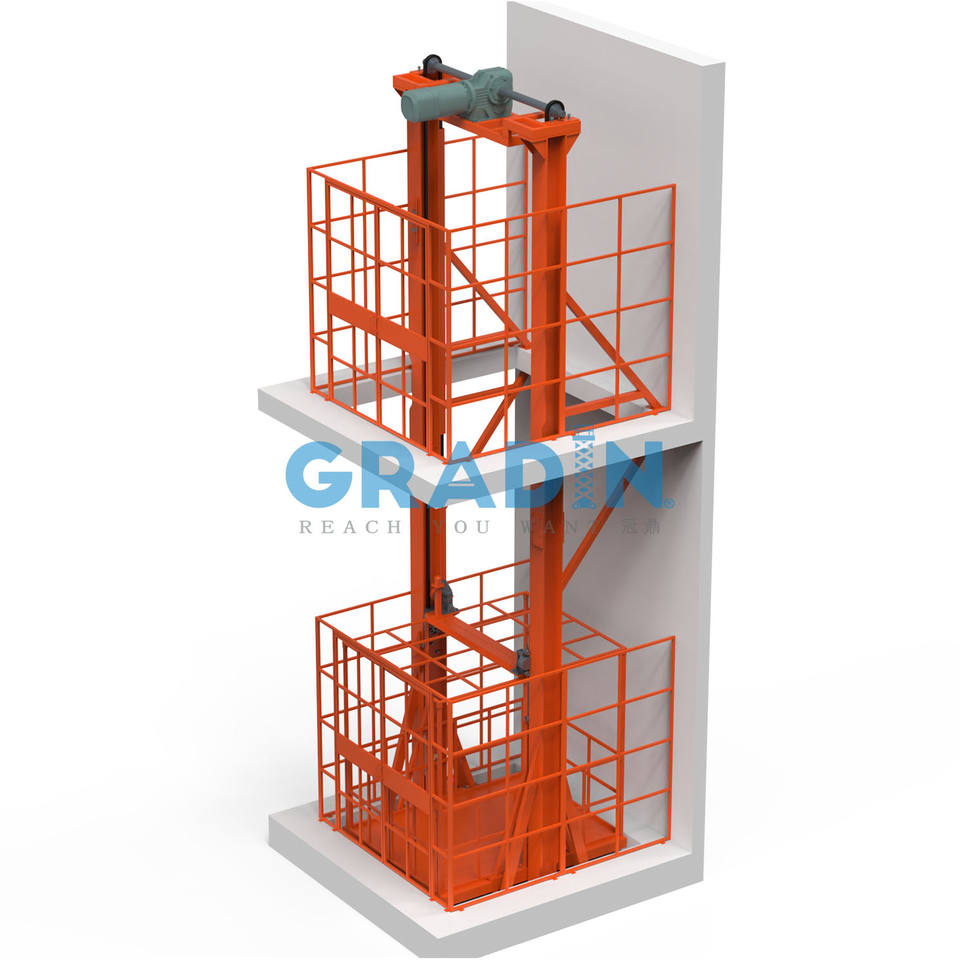

| Core Specifications | Model | VRC STRADDLE LIFT |

| Type | Chain-driven Vertical Reciprocating Conveyor (Straddle Type) | |

| Design | Continuous, Reciprocating | |

| Brand | Gradin | |

| Origin | Shandong, China | |

| Mechanical Performance | Lifting Drive | AC Electric Motor |

| Guiding System | Elevator-Grade Guide Rails & Chains | |

| Platform Size (WxD) | 500 x 500 mm (Standard) | |

| Platform Shape | F-shaped (Straddle) | |

| Platform Floor | Customizable (e.g., anti-slip steel, stainless steel) | |

| Lifting Speed | Up to 60 m/min | |

| Rated Load Capacity | Customizable (Based on application requirements) | |

| Electrical & Control | Power Supply | AC 110/220/230/380/415V (Configurable) |

| Control System | Programmable Logic Controller (PLC) | |

| Operation | Automated with call/send functions, multiple stop points | |

| General Features | Color | Customizable (Standard powder-coated finish) |

| Primary Applications | Hotels, Restaurants, Retail Stores, Workshops, Warehouses, Farms, Construction Sites, etc. |

Challenge

- Chronic Congestion & Delays: Staff and goods competed for elevator space, leading to prolonged wait times and congestion in service corridors.

- Hygiene and Contamination Risks: The simultaneous transport of food, clean linens, and waste in confined spaces posed a significant risk of cross-contamination.

- High Labor Costs & Inefficiency: Significant staff hours were wasted waiting for elevators or making multiple trips, driving up operational costs.

- Reduced Guest Service Capacity: The use of service elevators for logistics reduced their availability for guest luggage and staff mobility, potentially affecting the guest experience.

Workflow

- Platform & Enclosure: The platform was finished with a 304-grade stainless steel, non-slip floor for easy cleaning and food safety compliance. A hygienic, powder-coated enclosure with clear viewing panels was added for safety and load verification.

- Drive System & Control: The system utilizes a powerful yet smooth AC electric drive (configured for 220V), offering quiet operation essential for a hotel environment. The Programmable Logic Controller (PLC) was programmed with multiple stop points and access codes. For instance, the basement loading dock has unrestricted access, while upper-floor discharge points require key-switch activation, ensuring security and controlled access to supplies.

- Safety & Reliability: It features elevator-grade guide rails for exceptionally smooth and stable travel, along with multiple safety interlocks, gate sensors, and overload protection, ensuring complete compliance with material handling safety standards.

Quantifiable Benefits

- Increased Efficiency: Reduced average wait time for goods transportation by over 70%. The dedicated system freed up passenger elevators, improving guest experience.

- Labor Optimization: Saved an estimated 15-20 staff-hours per day previously spent waiting for elevators or making multiple trips with carts.

- Enhanced Safety & Hygiene: Eliminated cross-contamination risks by separating food and linen transport from waste removal paths. The enclosed, secure transport also reduced pilferage and damage.

- Space Savings: The compact, self-supported design occupied minimal valuable back-of-house space, a critical advantage in urban hotel design where maximizing usable area is paramount.

- Improved Staff Satisfaction: Back-of-house operations became less chaotic and more predictable, improving staff morale and productivity.