11.18.2025 / 5-minute read

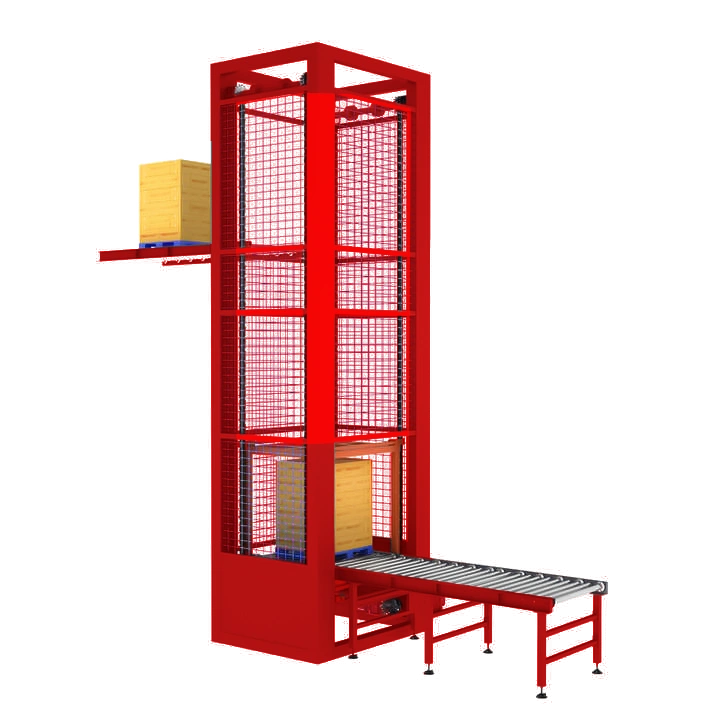

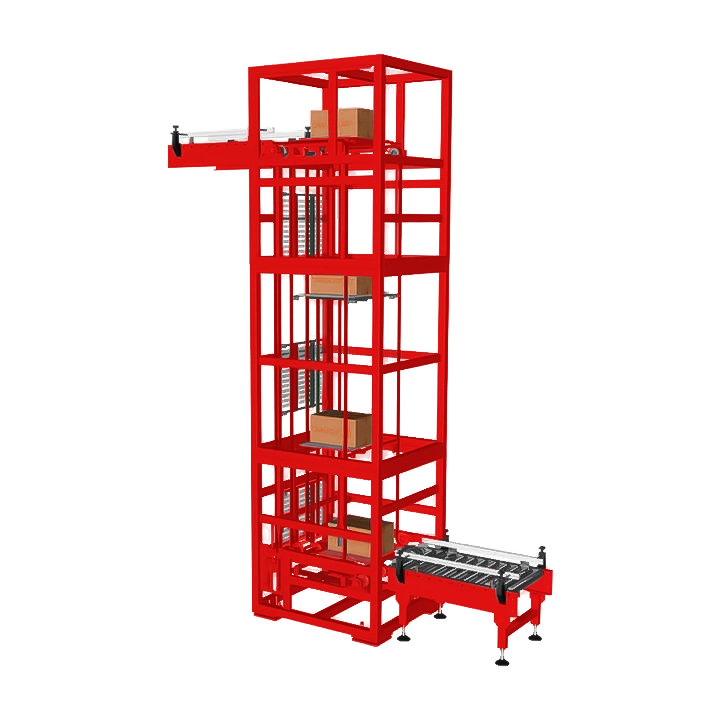

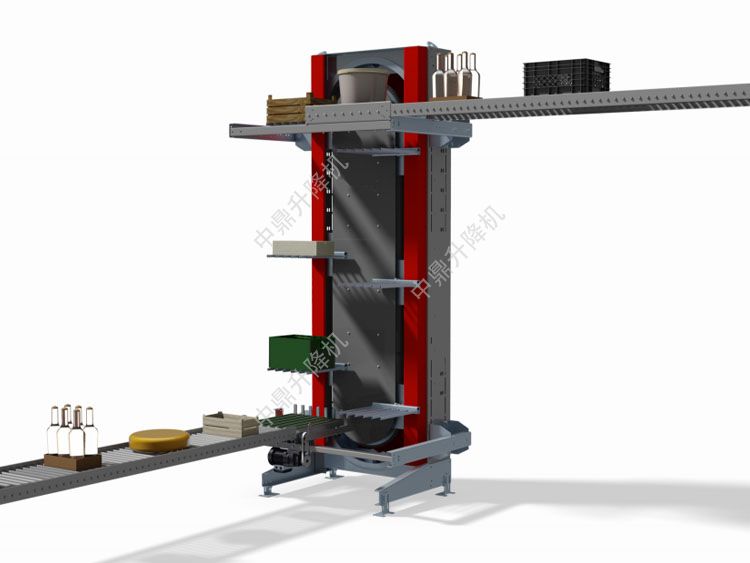

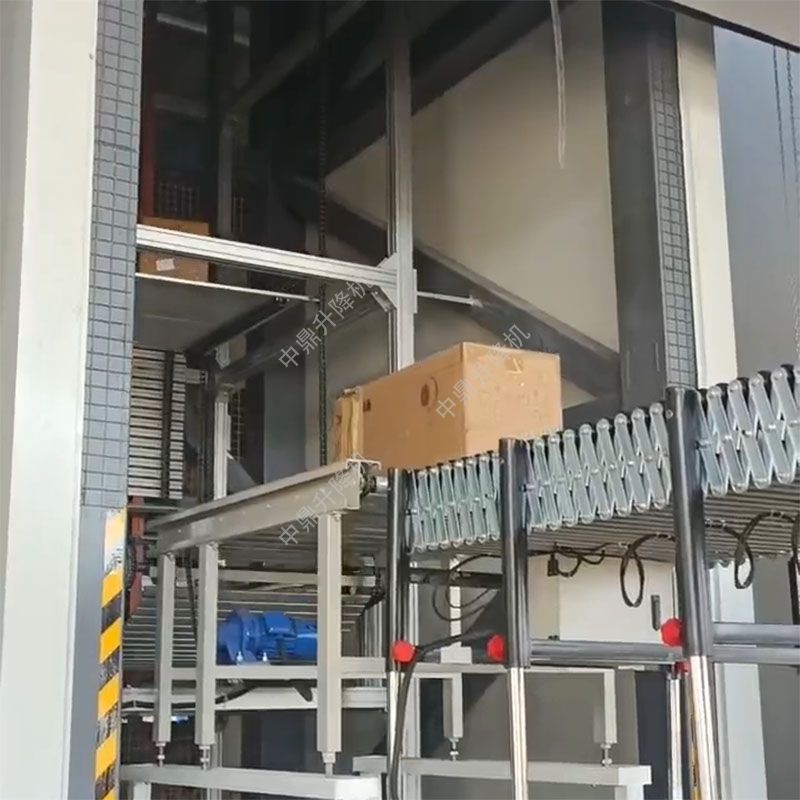

Continuous Vertical Conveyor for Food & Beverage Processing | High-Density Vertical Transport

Project Overview

Client: Regional Food & Beverage Processing Plant

Industry: Food & Beverage Processing

Application: Multi-Level Production Line Integration

Core Challenge: To enable efficient, continuous vertical transportation of packaged food products between three production levels while maintaining hygiene standards and maximizing throughput in limited floor space.

Basic Parameters

| Item | Specification |

|---|---|

| Strap Material | Alloy steel |

| Material Options | Stainless steel, Carbon steel |

| Special Features | Easy to clean |

| Number of Layers | Customizable |

| Speed | Adjustable |

| Brand | Gradin |

| Place of Origin | Shandong, China |

| Applicable Industries | Hotels, Tailor Shops, Building Material Shops, Repair Shops, Manufacturing Plants, Food & Beverage Processing Plants, Farms, Restaurants, Home Use, Retail Stores, Grocery Stores, Printing Shops, Construction Sites, Energy & Mining, Catering Services, Advertising Companies, Others |

| Dimensions (L × W × H) | Custom |

| Warranty | 1 year |

| Frame Material | Carbon steel |

| Drive Method | Electric powered |

| Belt Color | Customizable |

| Conveying Height | ≤ 30 m |

| Load Capacity | ≤ 100 kg |

| Lifting Speed | 0–35 m/min (customizable) |

| Conveying Efficiency | 0–1500 pcs/h |

| Conveying Direction | Z-type / C-type / E-type / F-type |

| Optional Peripherals | Metal mesh, Color steel plate, PC sunboard, Tempered glass, Custom options |

Electrical Component

| 1. PLC | MITSUBISHI, SIEMENS, CUSTOM |

| 2. INVERTOR | DELTA, ABB, CUSTOM |

| 3. TRAVEL SWITCH | SCHNEIDER, OMRON, CUSTOM |

| 4. REDUCTION MOTOR | SEW, FLENDER, CUSTOM |

| 5. CONTROL CABLE | SHANGHAI LIBIN, DELIXI, CUSTOM |

Challenge

- Space Limitations: Insufficient floor space for conventional material handling equipment between production levels

- Throughput Bottlenecks: Existing manual methods couldn’t support required production volumes

- Hygiene Compliance: Needed easy-to-clean surfaces meeting food industry sanitation standards

- Process Integration: Required seamless connection between mixing, packaging, and labeling operations on different floors

Challenge

- Space-Optimized Design: Compact footprint minimized facility space requirements while connecting multiple levels

- Hygienic Construction: Stainless steel materials and easy-to-clean surfaces met food industry sanitation standards

- Continuous Operation: Circulating path design enabled non-stop material flow without workflow interruption

- Precise Control: Mitsubishi PLC and Delta inverter provided accurate speed and positioning control

- Flexible Configuration: Z-type conveying path optimized for facility layout between production levels

- Increased Throughput: Achieved 1500 pieces per hour vertical transportation capacity

- Space Optimization: 40% reduction in floor space required for inter-level material handling

- Labor Efficiency: Eliminated 3 manual material handling positions between levels

- Process Reliability: 99% uptime in continuous 24/5 operation