9.24.2025 / 5-minute read

Container Straddle Carrier – 35-Ton Heavy-Duty Handling Equipment for Port Logistics

Overview

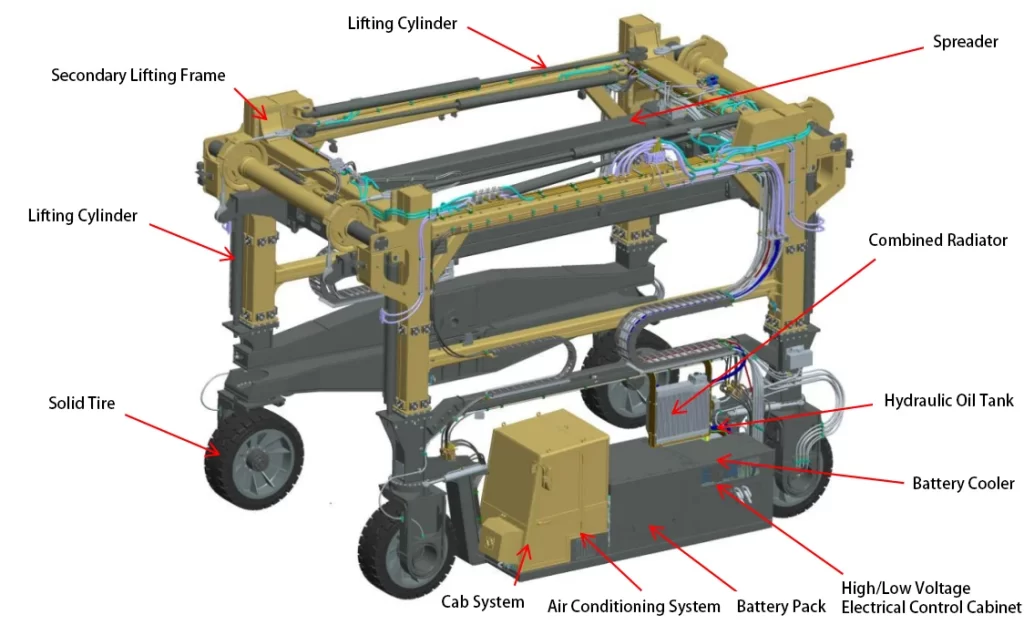

This case analysis introduces the GKYS3532B container straddle carrier, designed to address the core need for efficient container flow in modern ports and logistics hubs.

Featuring an innovative portal frame design, it integrates horizontal transport, stacking, and loading/unloading functions, effectively solving industry pain points including single-function equipment, multiple handling links, and low yard utilization in traditional terminal operations.

Basic Parameters

| Parameter Item | Technical Specification |

|---|---|

| Structure Type | Dual-lane independent structure |

| Rated Load | 135 tons (single lane) |

| Container Types Processed | 20-foot standard containers (customizable) |

| Flipping Angle | Adjustable from 0 to 180 degrees |

| Lifting Height | 800 mm |

| Lateral Movement | 2900 mm |

| Motor Power | 15 kW-18.5 kW |

| Power Supply Specifications | 380V/50Hz |

| Total Weight | 115.4 tons |

How It Works

The equipment maneuvers over container rows using its portal frame and engages containers with an automatic spreader.

A hydraulic system enables two-stage lifting (1500mm) for 1-2 high container stacking.

Powered by a closed travel system and supported by four solid tires, it moves flexibly at 3-5km/h, enabling rapid transfer of containers between the yard and quay cranes.

The Challenges

- Operational Efficiency Bottleneck: Single-lane design leads to slower container processing speeds, which cannot meet the throughput demands of modern ports.

- Low Space Utilization: Traditional equipment occupies large areas but has limited efficiency per unit area.

- Safety Challenges: High demands for stability and control precision during heavy-load flipping processes.

- Inadequate Adaptability: Fixed designs struggle to meet the diverse container processing needs.

- High Maintenance Costs: Equipment reliability and ease of maintenance are crucial in high-intensity operating environments.

Solutions

- Cab and remote control operation, equipped with heating and air conditioning.

- Multi-lifting point spreader, compatible with handling 10 to 50-foot containers.

- Crane-style open rebound hook for easy latch attachment.

- Equipped with audible and visual alarms, and a monitoring system.

- Wire rope utilizes a safety factor of 5-6.

- Lifting method: Hoisting + Jacking.

- Fitted with a microcomputer; emergency stops trigger a power-off memory function and include a self-locking feature.

- Four-wheel steering, two-wheel drive.

- Utilizes 1370*450 solid tires.

- Electrical system protection rating: IP55. Controller protection rating: IP65.

- Supplied with accompanying documentation (e.g., drawings, certificate of conformity).

- Hydraulic cylinders are equipped with balance valves to prevent falling.

- Features hydraulic quick-connect couplings for easy maintenance.

- The entire vehicle is equipped with a lighting system for nighttime operation.

- Includes a low-voltage protection system for overall vehicle safety.

- The lifting frame can traverse laterally 200mm left and right.

- The vehicle design incorporates a balance system to prevent tire slippage.

- Features an electro-hydraulic dual-control system for precision and safety.

- The hoisting cylinder is equipped with a limit system, ensuring an error of less than 2cm.

- The jacking system is equipped with a limit system, ensuring an error of less than 2cm.

- A limit system is installed between the spreader and the top beam.

- A displacement restriction module is in place between the spreader and the vehicle during operation.

- The equipment has self-diagnostic and alarm functions.

- Emergency stop buttons are located around the perimeter of the equipment.

- Effective lifting height: 4600mm.

- Includes a wireless module for real-time status feedback.

- Operable from the cab or via remote control.