8.19.2025 / 5-minute read

18m Heavy-Duty Reciprocating Elevator | 2000kg Beverage Raw Material Automation

Project Overview

Equipment End-user: A primary supplier to leading Chinese beverage companies.

Industry: Beverage Raw Material R&D & Manufacturing

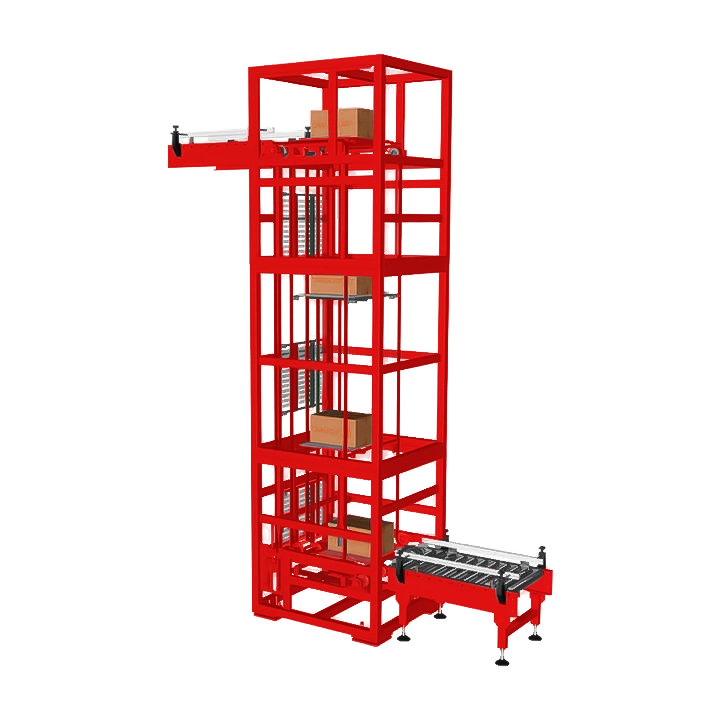

Objective: Automate vertical transport of heavy pallets (1700×1700×2400mm) across 4 floors (18m height).

Solution: Custom SJW2.0-18.0 elevator with intelligent control and safety systems.

Basic Parameters

| Parameter | Value |

|---|---|

| Payload | 2000kg |

| Lift Height | 18,000mm |

| Positioning Accuracy | ±5mm |

| Speed | 36m/min (Adjustable) |

| Stations | 4 Floors / 4 Stops |

| Safety | 4 Fire-rated Curtain Doors + Light Grids |

The Challenge

- 18m lift height requiring anti-sway structure

- 2000kg dynamic load demanding ultra-robust chains/guides

- ±5mm pallet docking precision

- Food-grade hygiene compliance

Solutions

Structural Reinforcement

- Main frame: 150×4mm steel tubes (Laigang Group)

- Lifting system: T90 elevator guides + 20B industrial chains (Donghua)

Precision Control

- Drive: SEW 15.5kW gearmotor + Siemens PLC

- Safety: Elevator-grade arrestor + Yuxi light curtains

Industry Adaptation

- Sanitary 304 stainless steel car (TISCO)

- 4 fire-rated high-speed doors