6.6.2025 / 4 minute read

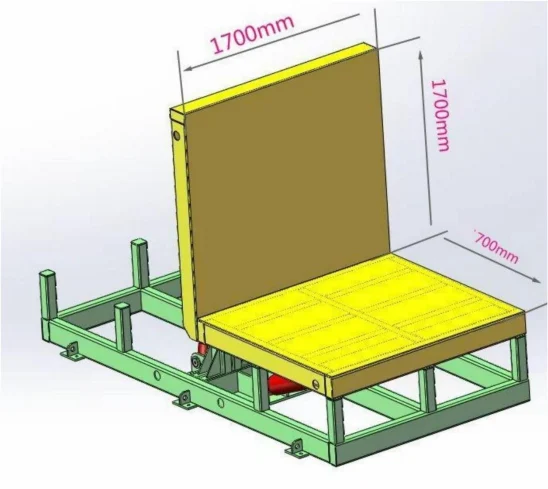

10-Ton 90° Hydraulic Tipping Machine for Sheet Metal Flipping

Project Overview

Product Name: Hydraulic Tipping Machine

Model: FZPT-10000

Function: Designed for 90° precision flipping of steel plates and pipes

Core Value: Driven by a hydraulic system to flip heavy workpieces, replacing manual lifting and enhancing safety and efficiency

Basic Parameters

| Parameter | Specification |

|---|---|

| Load Capacity | 10 tons (10000 kg) |

| Platform Size | 1700×1700 mm (main platform) |

| Extended Platform | 1700×700 mm (optional) |

| Flipping Angle | 0°→90° (vertical flipping) |

| Flipping Speed | Adjustable (controlled by one-way throttle valve) |

| Hydraulic Oil Type | Summer: 46# anti-wear hydraulic oil <br> Winter: 32# anti-wear hydraulic oil |

| Maintenance Cycle | Replace hydraulic oil and clean tank every 1200-1500 hours |

Main Structure and Working Principle

Flipping System

- Consists of base, platform, flipping cylinder, skirt board, and bearings

- Hydraulic cylinder drives the platform to flip by extending and retracting

Hydraulic System

- Includes electric motor-driven oil pump, electromagnetic reversing valve, lifting cylinder, one-way throttle valve, hydraulic oil tank, and pipelines

- Motor powers gear oil pump to output pressurized oil

- Electromagnetic valve distributes oil to flipping cylinder for upward flips

- Button activates valve to switch oil flow for downward flips

- Two throttle valves control speed during flipping

Gear Oil Pump

- High-speed gear oil pump powered by motor

- Suction pipe must be airtight to maintain efficiency and prevent noise

Hydraulic Oil

- Typically uses 46# anti-wear hydraulic oil (32# in winter)

- Clean oil tank and filter, and replace hydraulic oil after 1200-1500 hours of operation

Safety & Maintenance

Safety Features

- Throttle valves control speed

- Relief valves limit pressure

- Emergency manual release

Critical Maintenance

- Replace fluid & filters at 1,200hrs

- Monthly cylinder seal checks

- Quarterly bearing lubrication

Optional Upgrades

Automation Kit

- – PLC control (±0.5° accuracy)

- – Angle sensors feedback

Arctic Package

- -30℃ hydraulic fluid

- Electrical heating system

Dual-Platform

- 20-ton synchronized rotation