9.18.2025 / 5-minute read

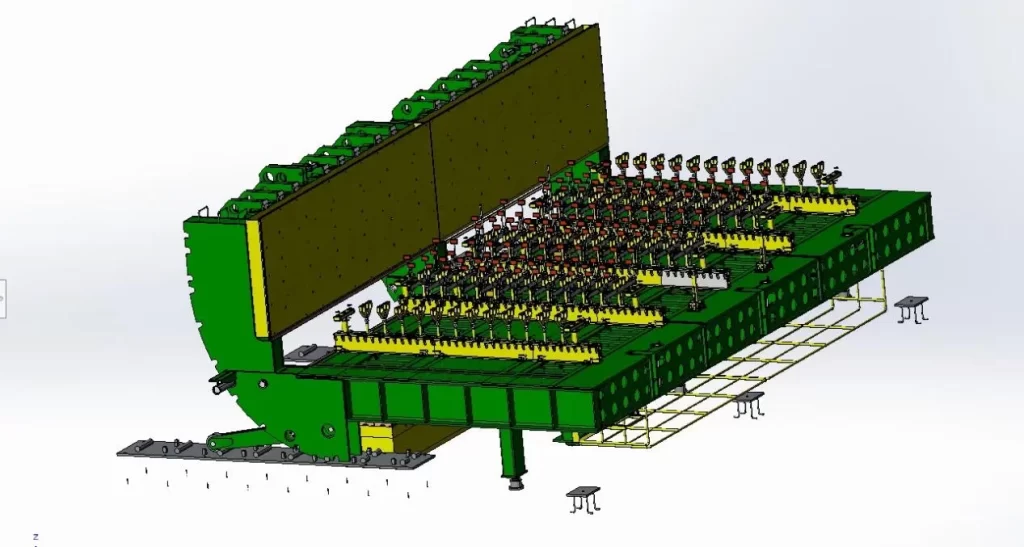

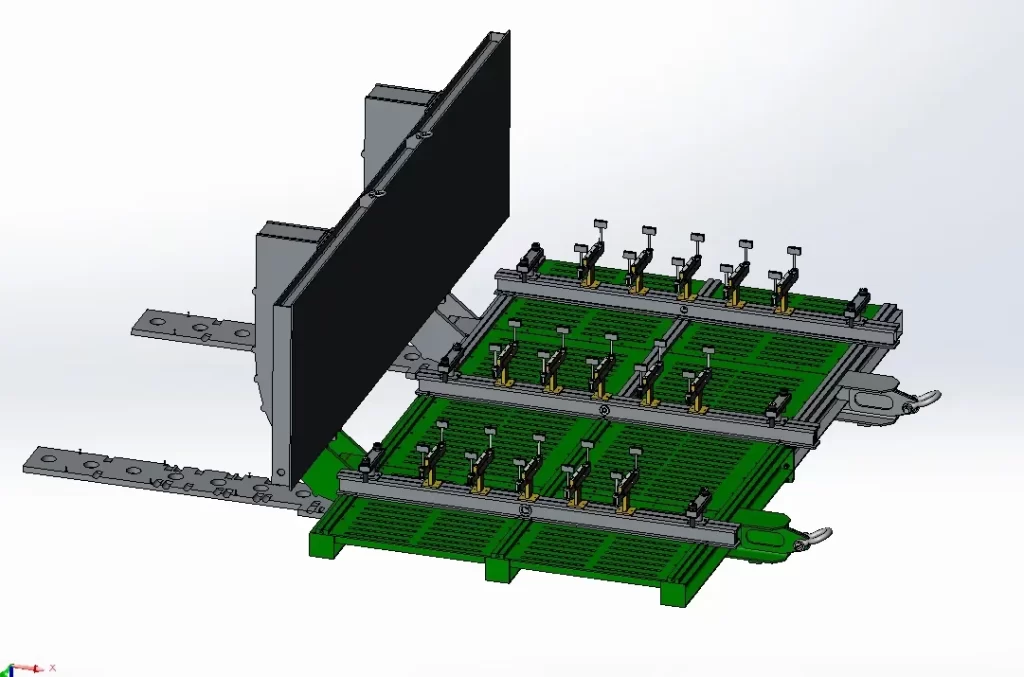

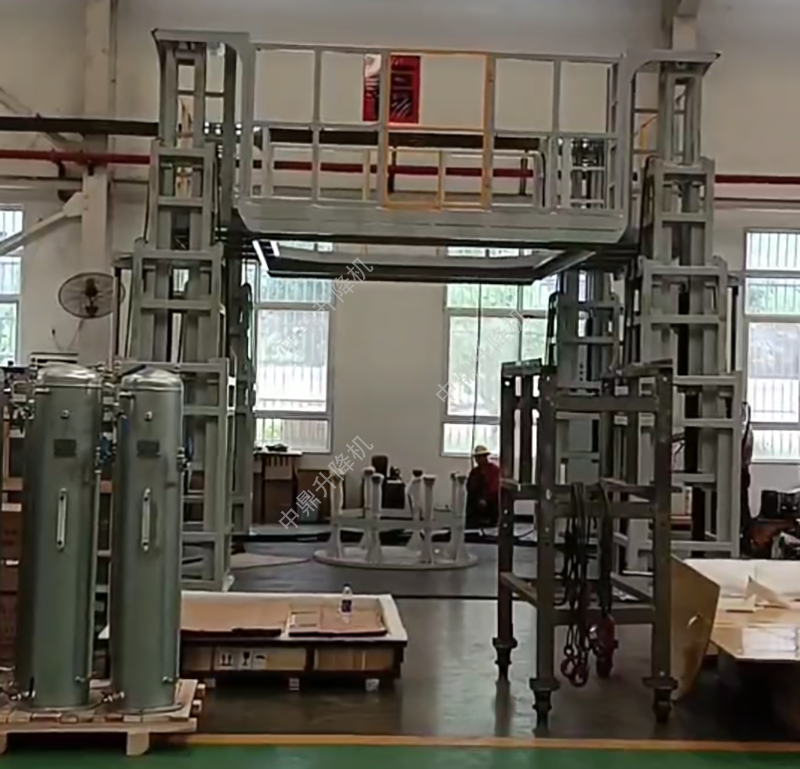

Modular Transformer Core Turning System – No Pit Required · Crane-Powered · Integrated Stacking & Turning

Overview

This case analysis introduces a modular core turning system designed for stacking and turning iron cores of large and medium-sized transformers.

Featuring a flexible building-block configuration and mechanical turning operation, the system adapts to diverse core window sizes, requires no pit foundation or external power, and significantly enhances operational economy and safety.

Basic Parameters

| Parameter | Specification |

|---|---|

| Core Window Size | Customizable (modular compatibility) |

| Load Capacity | Configurable (supports large/medium cores) |

| Table Surface Flatness | < 3mm (throughout turning process) |

| Vertical Alignment Error | < 2mm (before and after turning) |

| Power Source | Workshop crane (no external energy) |

| Structure Material | Hot-rolled section steel / low-carbon steel |

| Safety Feature | Automatic anti-tip flip legs |

How It Works

The system utilizes a modular frame structure that can be flexibly assembled to match various core window sizes.

The turning process is powered by the workshop crane, which drives the mechanical linkage to achieve a smooth 90° rotation of the core.

Flip legs automatically deploy after rotation to prevent tipping.

The table surface is machined and aged to ensure high flatness, with total deformation limited to under 3mm.

The Challenges

- Size Adaptation: Traditional fixed equipment could not accommodate varying core window sizes.

- High Civil Work Cost: Dedicated pits and foundations occupied space and increased investment.

- Energy Dependency: Hydraulic/electric turning systems required external power, raising operational costs.

- Safety Risks: Cores were prone to deformation or tipping during turning, threatening product quality and personnel safety.

Solutions

- Ultimate Precision Control: A multi-axis synchronous servo system ensures ±0.5mm positioning accuracy.

- Comprehensive Safety: Dual redundant safety systems, fall protection, and integrated safety connection points create multiple layers of security.

- High Customizability: The design supports various configurations, including U-type scissor platforms, to accommodate different aircraft models.

- Aerospace-Grade Materials: Construction utilizes aerospace aluminum and stainless steel for an optimal combination of lightweight properties and durability.

- Intelligent Control System: A user-friendly interface streamlines operations and enhances workflow efficiency.

- Environmental Resilience: A wide operational temperature range ensures performance across diverse aerospace environments.