9.10.2025 / 5-minute read

Pit-Mounted Lifting Turner for Australian Concrete Panel Production

Overview

This case analysis details a pit-mounted lifting and turning machine developed for the Australian construction prefabrication industry.

Designed specifically for precast concrete panel production lines, it innovatively integrates lifting, turning, and conveying functions to achieve fully automated conversion of heavy concrete panels from vertical to horizontal states, providing a comprehensive solution for material reorientation and transfer in precast component manufacturing.

Basic Parameters

| Parameter | Value/Description |

|---|---|

| Rated Load | 1500 kg |

| Platform Size | 3000×800 mm |

| Turning Angle | 90 degrees |

| Lifting Stroke | 300 mm |

| Station Points | 2 stops/2 stations |

| Equipment Type | Integrated Lifting & Turning |

| Drive Power | 4KW Hydraulic Power Unit |

| Cylinder-Lifting | φ90-70×2 units |

| Cylinder-Turning | φ80-60×2 units |

| Working Height | Pit-mounted (flush with floor) |

How It Works

The equipment is installed in a pit, with its platform normally flush with the floor.

When a vertically positioned concrete panel arrives, the lifting mechanism first elevates 300mm to align the roller conveyor with other transfer lines for loading.

The turning mechanism then activates, driven by two φ90 cylinders, to precisely rotate the 1.5-ton panel 90 degrees to a horizontal position.

Finally, the powered rollers start to convey the horizontal panel to the next process station, completing the fully automated operation.

The Challenges

Construction precast production lines face several critical challenges:

- Manual turning of heavy concrete panels (1.5 tons) poses significant safety risks

- Conventional equipment cannot achieve automated vertical-to-horizontal conversion

- Limited production space requires space-saving solutions

- Inefficient transfer between processes affects overall productivity

- Customized equipment needed to adapt to existing line height and interface requirements

Solutions

- Integrated Design: Combines lifting, turning, and conveying functions

- Space Optimization: Pit-mounted installation saves valuable floor space

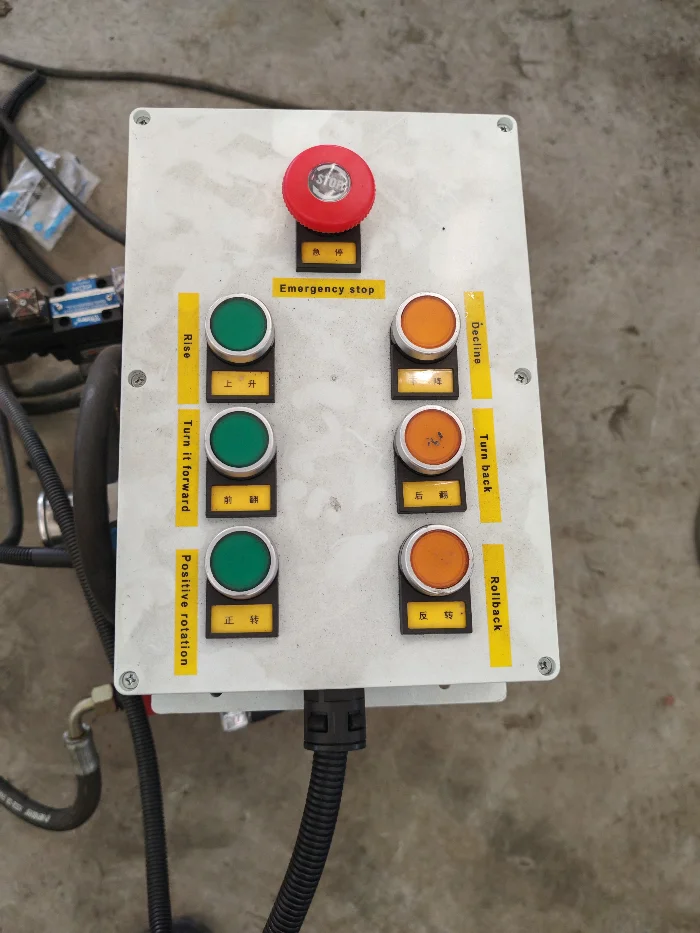

- Safety Assurance: Hydraulic drive with mechanical limits ensures safe handling

- Seamless Integration: Powered rollers enable perfect connection with conveyors

- Customized Design: Tailored to specific panel dimensions (2700×600×490mm)

- Automated Operation: Enables fully automated material handling process