9.25.2025 / 5-минутное чтение

Электрический контейнерный стрэддл-карриер - решение с нулевым уровнем выбросов для "зеленых" портов

Обзор

В данном анализе представлен электрический контейнерный стрэддл-перевозчик, разработанный для удовлетворения двойных требований - защиты окружающей среды и операционной эффективности в современных портах и логистических центрах.

Благодаря инновационной системе электропривода и конструкции портальной рамы, оборудование обеспечивает нулевой уровень выбросов, низкий уровень шума и высокую эффективность операций по перевалке контейнеров, представляя собой идеальное решение для развития "зеленого" порта.

Основные параметры

| Параметр | Модель 35T | Модель 60T | Модель 80T |

|---|---|---|---|

| Номинальная мощность | 35 тонн | 60 тонн | 80 тонн |

| Ширина внутренней рамы | 3200 мм | 3700 мм | 3700 мм |

| Высота подъема | 1550 мм | 1700 мм | 1700 мм |

| Скорость движения | 5-7 км/ч | 3-5 км/ч | 3-5 км/ч |

| Мощность двигателя | 80 КВТ | 90 КВТ | 120 КВТ |

| Радиус поворота | 7000 мм | 10000 мм | 12000 мм |

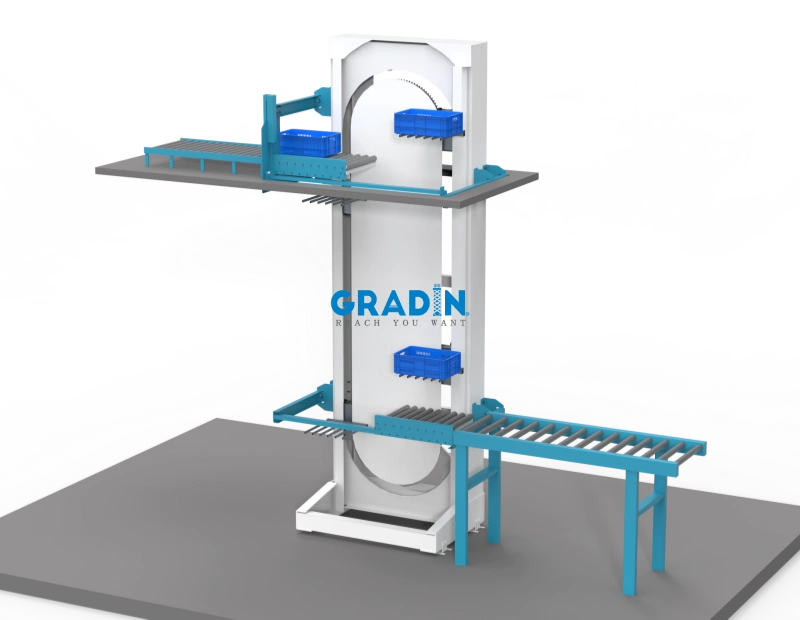

Как это работает

В оборудовании используется синхронный двигатель с постоянными магнитами и литий-железо-фосфатные аккумуляторы большой емкости.

Профессиональные разбрасыватели с гидравлическим управлением обеспечивают точную обработку контейнеров, а шасси на резиновых шинах - гибкую мобильность.

Интеллектуальная система управления координирует функции подъема, перемещения и рулевого управления для быстрого перемещения контейнеров по территории склада.

Проблемы

- Давление окружающей среды: Высокие выбросы традиционного дизельного оборудования не отвечают требованиям "зеленого порта

- Операционные расходы: Постоянно растущие расходы на топливо влияют на рентабельность

- Шумовое загрязнение: Громкая работа влияет на рабочую среду и окружающее население

- Расходы на содержание: Сложное обслуживание дизельных двигателей приводит к длительным простоям

Решения

- Система чистого электропривода

- Синхронные двигатели с постоянными магнитами с КПД более 95%

- Безопасные и надежные литий-железо-фосфатные батареи с длительным сроком службы

- Интеллектуальное управление энергией

- Система рекуперации энергии торможения

- Интеллектуальные стратегии зарядки/разрядки для оптимизации энергопотребления

- Малошумная конструкция

- На 20 дБ меньше шума по сравнению с дизельными двигателями

- Оптимизированное снижение шума гидравлической системы

- Удобство обслуживания

- Интервалы технического обслуживания двигателя 10 000 часов

- Система дистанционной диагностики неисправностей