8.5.2025 / 5 минут чтения

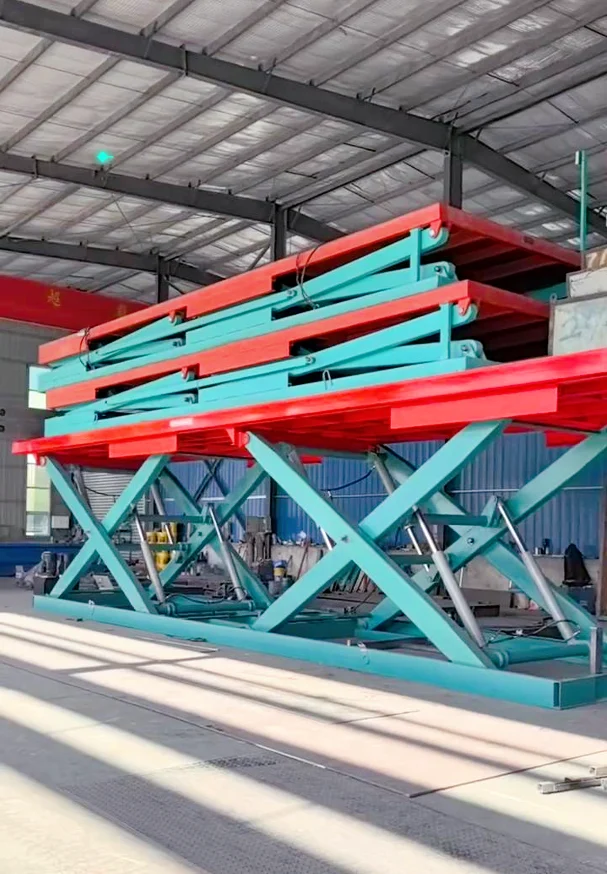

Двухножничная синхронизированная система подъема: Решение сложных задач промышленной сборки с точностью до миллиметра

Обзор проекта

Созданная специально для промышленного производства/сборки, эта двухножничная синхронная подъемная платформа поднимает грузы весом 3000 кг на высоту 4 м с помощью синхронизированной гидравлики, заменяя ручное управление и повышая эффективность/безопасность.

Основные параметры

| Модель продукта | SJG3.0-4.0 |

|---|---|

| Размер подъемной платформы | 2000*750 мм |

| Необходимое пространство Размер | 2100*850 мм |

| Высота штока | 4000 мм |

| Номинальная нагрузка | 3000 кг |

| Оборудование Самовывоз | 800 мм (включает высоту колес, четыре универсальных колеса) |

| Скорость подъема | 2-3 м/мин |

| Общая картина | Желтый + черный |

| Структура | Два ножничных вила + синхронный мотор + гидравлическая насосная станция + система управления |

| Конструкция ножничных вил | Однопролетный, трехслойный |

Вызов

- Точность синхронизации: Двойные ножничные рычаги должны подниматься синхронно (отклонение ≤2 мм), чтобы предотвратить опрокидывание груза или гидравлическую перегрузку.

- Соответствие требованиям безопасности: Сертификация CE, требующая отчетов FMEA и испытаний на перегрузку 150%.

- Компактная интеграция: Гидравлический блок и блок управления размещаются на площади 2100×850 мм (800 мм собственной высоты с роликами).

Решения

- Гидравлика с замкнутым циклом: Синхронный распределитель потока + датчики перемещения обеспечивают отклонение <1,5 мм.

- Резервирование безопасности: Балансировочные клапаны + механические замки для обеспечения безопасности при отключении электроэнергии; 120% протестирован под нагрузкой и имеет заключение SGS.

- Оптимизация пространства: Гидравлические/контрольные блоки, встроенные в основание ножниц, с охлаждающими каналами для условий окружающей среды 40℃

Преимущества

✅ Суб-2 мм синхронизация: Обеспечивает стабильность нагрузки и продлевает срок службы.

✅ Полное соответствие стандартам: CE-сертификация с отчетами об испытаниях для глобальных клиентов.

✅ Экономия труда: скорость 2-3 м/мин сокращает 3 трудочаса на цикл, сокращая сроки на 30%.

✅ Компактность: Ролики и низкий профиль подходят для ограниченного пространства.

✅ Heavy-Duty: марганцевая сталь + хромированные стержни для 100 тыс. циклов в течение 10 лет.