7.5.2025 / 5 минут чтения

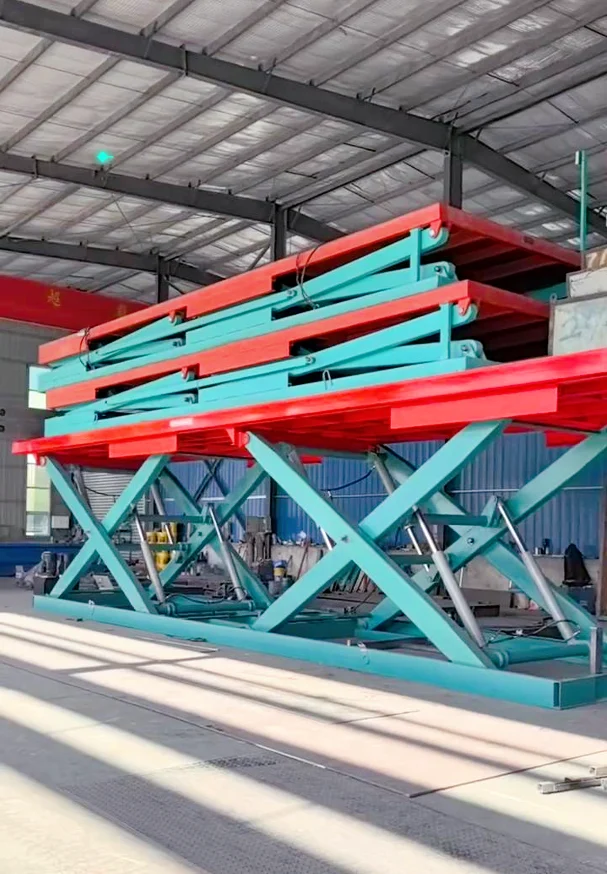

Ножничная подъемная платформа из нержавеющей стали 316 для транспортировки бункеров

Обзор проекта

Клиент является ведущей компанией в китайской индустрии рисового вина (Huangjiu) с более чем 350-летней историей и годовым объемом производства более 300 000 тонн. Они занимают 40% долю рынка в элитном сегменте. Строгие условия производства (высокая влажность, пар, частая очистка) требуют оборудования, устойчивого к коррозии, отвечающего санитарно-гигиеническим требованиям и способного к автоматизации.

Этот ножничный подъемник из нержавеющей стали 316, разработанный для работы в суровых условиях ликероводочного завода, позволяет транспортировать бункеры с высокой частотой, отвечая требованиям антикоррозийности, гигиены и автоматизации. Он легко интегрируется с центральной системой управления, обеспечивая точность работы.

Основные параметры

| Артикул | Спецификация/параметр |

|---|---|

| Размер платформы (мм) | 1700 * 1400 |

| Размер ямы (мм) | Не требуется яма |

| Направление входа/выхода (мм) | Сквозной вход/выход |

| Высота перемещения (мм) | > 1900 (без учета высоты оборудования) |

| Номинальная нагрузка (кг) | ≥ 2600 |

| Количество остановок/станций | / |

| Уровень оборудования | Обычный/Стандартный |

| Тип структуры | 2-этажный 1-спальный |

| Высота оборудования (мм) | 600 |

Вызов

- Точное выравнивание и стабильность: Высокочастотная работа требует бесперебойной стыковки с конвейерными цепями и отсутствия риска перекоса или падения.

- Соответствие жестким условиям окружающей среды: Устойчивость к парам спирта, чистящим средствам и гигиеническим стандартам GMP.

- Сложность системной интеграции: Связь в реальном времени с центральными системами управления, требующая нулевой задержки

Решения

- Управление ПЛК Siemens S7-1200: Интегрировано по протоколу PROFINET для автоматического планирования и обратной связи по состоянию в режиме реального времени.

- Система защиты от падения при выравнивании: Двойное позиционирование с фотоэлектрическими датчиками и механическими ограничителями (погрешность ≤±1 мм); гидравлические блокировочные клапаны для безопасности при отключении питания.

- Полностью из нержавеющей стали: Нержавеющая сталь 316 с лазерной бесшовной сваркой, исключающей риск коррозии и загрязнения.

Преимущества

✅ Долговечность пищевого класса: нержавеющая сталь 316 (сертифицирована FDA) устойчива к воздействию алкоголя, химикатов и высокотемпературного пара.

✅ Высокая степень автоматизации: Интеграция центрального управления повышает эффективность 40%, обеспечивая круглосуточную работу.

✅ Резервирование безопасности: Система защиты от падения с уровня + защита от перегрузки, коэффициент неисправностей <0,1%.

✅ Компактность и прочность: Наземная конструкция экономит место; срок службы более 10 лет при нагрузке 2600 кг.

✅ Простота обслуживания: Модульная структура позволяет быстро заменять ключевые компоненты (например, ПЛК, гидравлические клапаны).