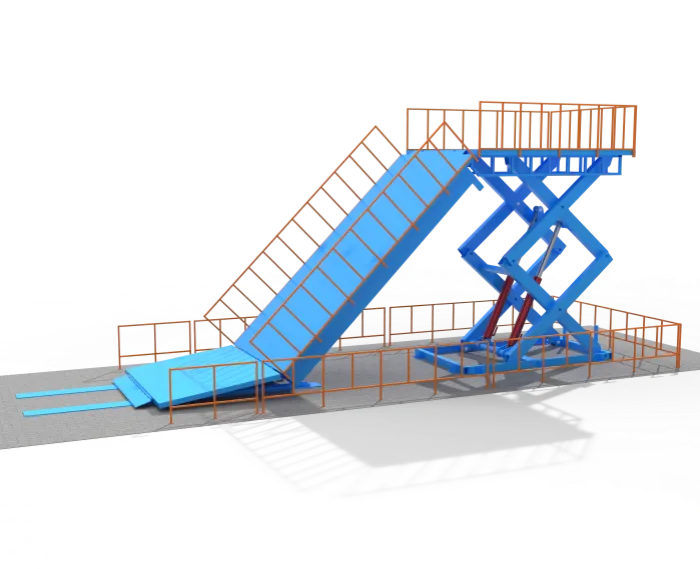

Plataforma elevatória de tesoura inclinada para teste de taludes

Essa plataforma elevatória tipo tesoura pode ser usada para uma variedade de necessidades de teste de inclinação. A plataforma de elevação pode operar o ângulo de inclinação sem fio e remotamente, e o atrito de diferentes inclinações pode ser personalizado de acordo com as necessidades. Ela pode ser usada para testar vários veículos, máquinas e equipamentos em diferentes setores.

Para saber mais fale com nossa equipe

Especificação

| Item | Descrição da especificação |

|---|---|

| Modelo | Série SLP-ST |

| Carga nominal | 2000-10.000 kg (cargas maiores podem ser personalizadas) |

| Altura de elevação | 0,5-5 m (maior altura de deslocamento personalizável) |

| Tamanho da plataforma | Tamanho padrão: 2m × 4m (comprimento/largura personalizados disponíveis, suporte máximo de 5m × 10m) |

| Faixa de ajuste de inclinação | 0°-30° (expansível até 45°, precisão de ±0,5°) |

| Ajuste de fricção | Suporta simulação de fricção personalizada (são necessários parâmetros específicos) |

| Método de controle | Controle remoto sem fio + controle de tela sensível ao toque (controle remoto PLC/IoT opcional) |

| Precisão do ajuste de ângulo | ±0.5° |

| Sistema de energia | Acionamento hidráulico / acionamento elétrico (opcional) |

| Necessidade de energia | Alimentação trifásica de 380 V/50 Hz (opcional 220 V ou alimentação a diesel) |

| Peso do equipamento | 2.500-8.000 kg (personalizado com base no tamanho e na carga) |

Recursos

🔹 Simulação de declive: Nossa plataforma foi projetada para testes de inclinação e pode reproduzir com precisão vários ângulos de inclinação para simular situações reais.

🔹 Controle preciso: Nossa plataforma é equipada com um sistema de controle avançado que pode ajustar com precisão o ângulo de inclinação para atender com precisão aos requisitos de teste.

🔹 Medidas de segurança: Nossa plataforma tem recursos de segurança incorporados, como grades de proteção, botões de parada de emergência e proteção contra sobrecarga, que priorizam a segurança dos operadores durante os testes.

🔹 Design amigável ao usuário: Nossa plataforma é fácil de usar, com controles intuitivos e elementos de design ergonômico para uma operação eficiente.

Informe-se aqui

Opções e acessórios

| Categoria | Opção/Acessório | Descrição |

|---|---|---|

| Controle e operação | 1. Sistema de controle remoto de IoT | Permite o monitoramento remoto, o armazenamento de dados na nuvem e a coordenação de vários dispositivos. |

| 2. Módulo de programação de automação PLC | Sequências de teste pré-programadas para operação automatizada sem supervisão. | |

| 3. Interface de tela sensível ao toque em vários idiomas | Suporta chinês/inglês/alemão/japonês, entre outros, para uma operação intuitiva. | |

| Aprimoramentos de segurança | 1. Sensores de colisão a laser | Detecta obstáculos e aciona o desligamento automático para evitar colisões. |

| 2. Sistema de travamento hidráulico duplo | Travas hidráulicas redundantes para evitar inclinação ou deslizamento acidental. | |

| 3. Componentes elétricos à prova de explosão | Certificado para uso em ambientes inflamáveis ou explosivos (por exemplo, mineração, testes químicos). | |

| Simulação ambiental | 1. Módulo de simulação de temperatura e umidade | Simula condições extremas (-40°C a +80°C, 10%-95% de umidade; requer estrutura vedada). |

| 2. Kit de teste de spray de chuva/água | Simula condições de chuva com jatos de água ajustáveis com classificação IP. | |

| 3. Sistema de simulação de vento e areia | Ventiladores integrados e injeção de poeira para testes em ambientes desérticos ou com muita poeira. | |

| Aquisição e análise de dados | 1. Kit de sensores de alta precisão | Monitora a pressão, o torque, o deslocamento e o ângulo de inclinação (precisão de ±0,1%). |

| 2. Registrador de dados | Armazena 72 horas de dados contínuos com compatibilidade de exportação CSV/Excel. | |

| 3. Integração de software de terceiros | Compatível com LabVIEW, MATLAB ou sistemas de teste internos personalizados. | |

| Mobilidade e instalação | 1. Chassi móvel (rodas giratórias) | Chassi acionado eletricamente com rodízios com trava para facilitar a realocação. |

| 2. Adaptador de engate de reboque | Permite o transporte por caminhão ou reboque para testes ao ar livre. | |

| 3. Projeto modular de desmontagem rápida | Estrutura de estrutura dividida para facilitar a montagem em espaços confinados. | |

| Personalização da superfície da plataforma | 1. Placa de aço texturizada antiderrapante | Superfície de atrito aprimorada (sobreposições de grade de borracha/metal opcionais). |

| 2. Revestimento resistente à corrosão | Ideal para ambientes marinhos ou químicos (aço inoxidável opcional). | |

| 3. Superfície de adsorção magnética | Protege pequenos dispositivos ou robôs durante os testes para evitar deslizamentos. |

Temos orgulho de fornecer equipamentos de manuseio de materiais para todos os setores e para todas as aplicações

Os equipamentos de manuseio de materiais em seu setor

Os elevadores de mercadorias Gradin podem ser usados para transportar cargas de paletes de produtos acabados ou ingredientes, ou equipamentos, para cima e para baixo de um mezanino ou segundo andar. A plataforma do elevador pode ser fabricada em aço inoxidável, de modo que esteja em conformidade com as normas, não seja corrosiva e possa ser lavada.

Tendo em mente as lesões musculoesqueléticas, apresentamos a seguir uma lista útil, mas não exaustiva, de situações que geralmente surgem nos setores de manufatura e engenharia durante o processo de produção:

- Manipulação repetida da carga a uma distância do tronco do corpo.

- Flexão repetida do tronco para levantar a carga.

- Uma carga muito grande que é difícil de entender.

- Manuseio repetido da carga acima da altura dos ombros ou no nível do chão.

- Levantamento de peso que envolva torção do tronco.

- A carga precisa ser transportada por uma longa distância em uma área desordenada ou perigosa.

Quando as atividades de manuseio manual envolvem tais riscos de lesão (especialmente nas costas) devido a condições ergonômicas desfavoráveis, o princípio básico é que o empregador deve tomar medidas para reduzir ou eliminar o risco de lesão.

O elevador de mercadorias Gradin foi projetado especificamente para transportar paletes de tamanho padrão da fabricação para e do armazenamento em um mezanino ou primeiro andar. Se uma especificação padrão não atender a todas as suas necessidades, também nos especializamos em configurações sob medida, trabalhando em colaboração com você para garantir que a solução final seja perfeita para sua empresa, seus funcionários e seus produtos.