22.10.2025 / Leitura de 6 minutos

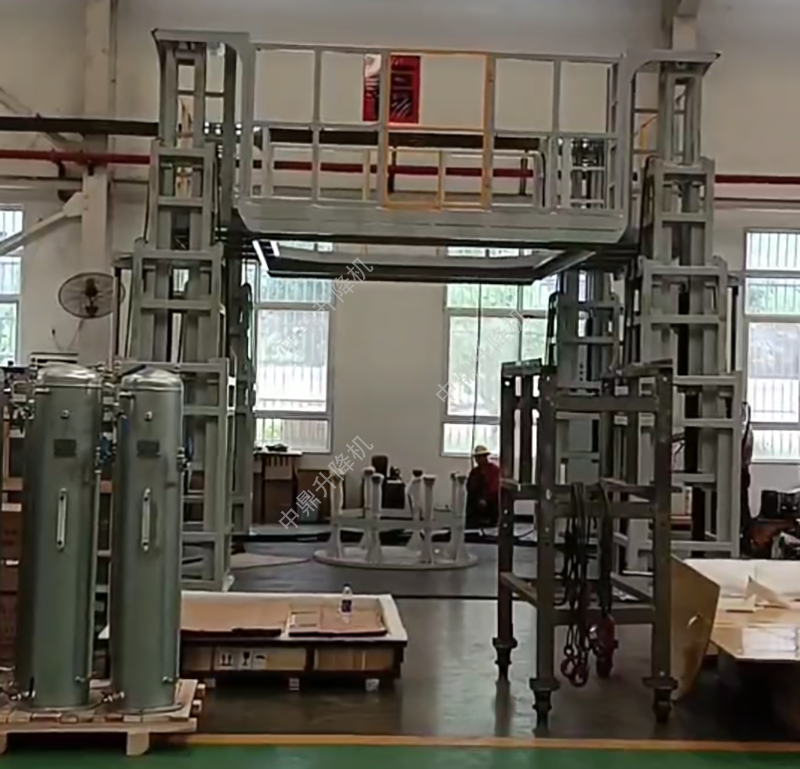

Mesas hidráulicas de empilhamento e giro de núcleo | 1-100 toneladas

Visão geral

Esta análise de caso investiga como a mesa hidráulica de torneamento e empilhamento de núcleos aborda os principais desafios da fabricação tradicional de núcleos de transformadores, trazendo melhorias revolucionárias em termos de eficiência e qualidade para a produção de transformadores de pequeno e médio porte.

Com seu design modular, controle hidráulico preciso, grande capacidade de adaptação ao processo e excepcional confiabilidade estrutural, a mesa hidráulica de torneamento e empilhamento de núcleos tornou-se um recurso indispensável nas modernas linhas de produção de núcleos de transformadores. Não se trata apenas de uma ferramenta para obter uma fabricação de núcleos de alta qualidade, mas de uma força motriz por trás do avanço do processo e dos ganhos de eficiência econômicos na produção de transformadores.

Parâmetros básicos

| Categoria de parâmetro | Item de especificação | Detalhes e especificações |

|---|---|---|

| Especificações do núcleo | Capacidade de carga | 1 ~ 100 toneladas (personalizável) |

| Tipos de núcleo compatíveis | Núcleo trifásico, núcleo de cinco membros, laminação | |

| Estrutura da plataforma | Combinação de blocos modulares (grande), design monobloco (pequeno) | |

| Métricas de precisão | Deformação da superfície da mesa | < 2 mm |

| Perpendicularidade (mesa de empilhamento vs. viga de giro) | < 2 mm (antes e depois do torneamento) | |

| Mecânica e estrutura | Ajuste do feixe | Feixes de movimento sincronizado em ambos os lados |

| Sistema de acionamento | Giro acionado por cilindro hidráulico | |

| Velocidade de giro | Ajustável | |

| Recursos de segurança | Pernas de apoio para giro (para estabilidade após giro de 90°) | |

| Material da estrutura | Aço laminado a quente ou estrutura soldada com baixo teor de carbono, com alívio de tensão | |

| Sistema hidráulico | Componentes principais | Componentes hidráulicos de marcas importadas (por exemplo, cilindros) |

| Sincronização | Excelente sincronização, garante núcleo livre de deformação | |

| Instalação e adaptabilidade | Requisito de instalação | Grande: Necessita de base; Pequeno: Sem base, fácil de mover |

| Adaptabilidade da janela principal | Montagem flexível com base no tamanho da janela do núcleo, Alta adaptabilidade | |

| Dimensões da superfície da mesa | Personalizado de acordo com os requisitos do cliente | |

| Compatibilidade de processos | Processos compatíveis | Adequado para Processo de não remoção do garfo superior & Processo tradicional |

| Compatibilidade de luminárias | A excelente sincronização garante núcleo livre de deformação |

Desafios e soluções

- Desafios tradicionais: O empilhamento e o torneamento tradicionais de núcleos dependiam muito de pontes rolantes e de trabalho manual, o que levava à ineficiência, à falta de sincronização e à possibilidade de deformação do núcleoA falta de segurança, os altos riscos de segurança e a baixa adaptabilidade a vários tamanhos de janelas.

- Otimização de processos: A mesa permite a amarração da cinta enquanto o núcleo está na horizontal, eliminando a necessidade de grampos auxiliares complexos usados na amarração vertical, simplificando as operações e reduzindo o tempo de ciclo. O Feixes de movimento síncrono em ambos os lados se ajustam com precisão para se adequar a diferentes diâmetros de coluna de núcleo (MO), garantindo ampla aplicabilidade

Projeto de confiabilidade

- Confiabilidade do componente principal: Crítico os componentes hidráulicos (por exemplo, cilindros) usam marcas importadasgarantindo estabilidade operacional de longo prazo e alta confiabilidade da fonte, reduzindo assim as taxas de falha.

- Resistência estrutural e precisão: A análise de elementos finitos (FEA) é usada na otimização do projeto, garantindo resistência e rigidez suficientes sob carga (1-100 toneladas). Métricas de alta precisão, como deformação da mesa <2 mm e erro de perpendicularidade <2 mm antes e depois do torneamento, fornecem uma base sólida para a qualidade do empilhamento do núcleo. O design das pernas de suporte de giro oferece proteção de segurança adicional após a rotação de 90 graus