30.4.2025 / Leitura de 6 minutos

Vazamento zero, serviço pesado: análise técnica de uma máquina de inversão hidráulica de 15 toneladas

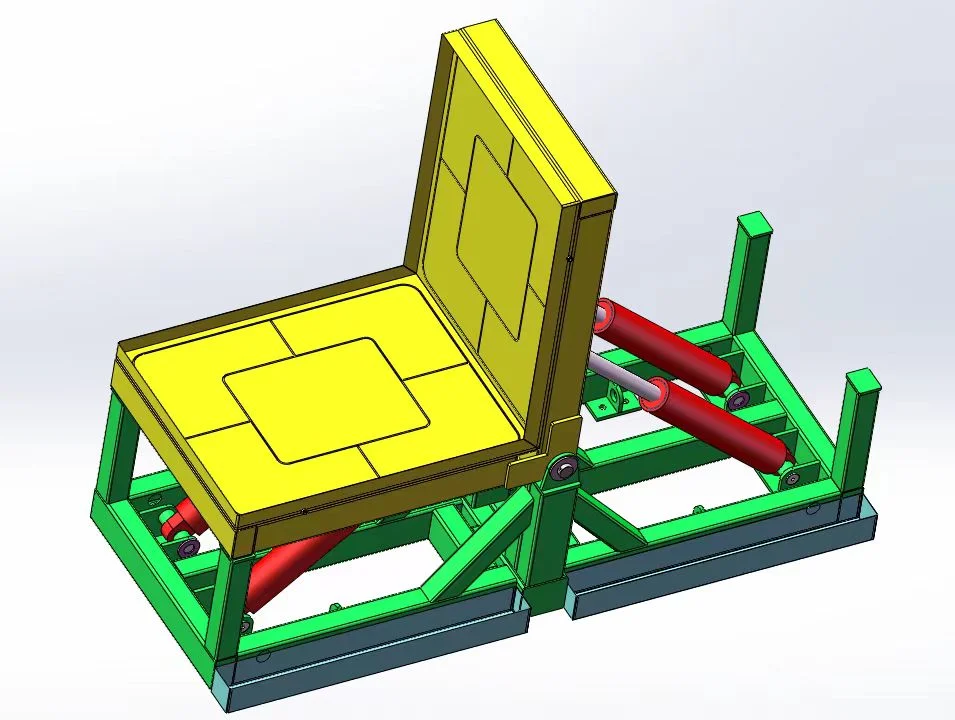

Visão geral do projeto

Essa máquina hidráulica de 15 toneladas foi projetada para limpeza, manutenção e reparo de componentes para serviços pesados (por exemplo, assentos de rolamentos).

Com plataformas duplas de 1500×2000 mm e giro de 90 graus, ele manuseia com segurança peças de trabalho grandes (até 1500×1500×1300 mm).

Os canais integrados de condução de óleo e as bandejas de coleta permitem a reciclagem de óleo residual, alinhando-se aos padrões de produção ecologicamente corretos para indústrias pesadas.

Parâmetros básicos

| Item | Especificação |

|---|---|

| Modelo | FZ15-90 |

| Tamanho da plataforma | 1500×2000mm + 1500×2000mm |

| Ângulo de inversão | 90° |

| Capacidade | 15 toneladas |

| Tempo de ciclo | 60s por flip |

| Controle | Controle de jog |

| Carregamento | Assistido por guindaste |

| Tipo de material | Assentos de rolamentos |

O desafio

- A limpeza de componentes pesados (por exemplo, assentos de rolamentos) exige uma inversão frequente, mas as ferramentas tradicionais são ineficientes e inseguras.

- O vazamento de óleo durante a limpeza pode causar contaminação ambiental, enquanto a coleta manual é cara.

- Peças de trabalho grandes (>1,5 m³) carecem de soluções de inversão estáveis e compatíveis com o tamanho.

Soluções

- Sistema hidráulico de plataforma dupla: Capacidade de 15 toneladas, ciclo de inversão de 60s, carregamento bidirecional.

- Gerenciamento de óleo ecologicamente correto: Os canais de guia de óleo + bandejas de coleta melhoram a reciclagem de óleo residual no 40%.

- Segurança industrial: A operação hidráulica suave suporta peças de trabalho de até 1500×1500×1300 mm.

Vantagens

- Alta eficiênciaO ciclo de inversão de 60s minimiza o tempo de inatividade.

- Conformidade ecológica: A reciclagem de óleo em circuito fechado reduz os riscos de poluição.

- Capacidade para serviços pesados: As plataformas duplas suportam cargas de 15 toneladas para componentes de grandes dimensões.

- Segurança operacional: O sistema hidráulico anti-vibração e o controle de jog evitam danos à peça de trabalho.