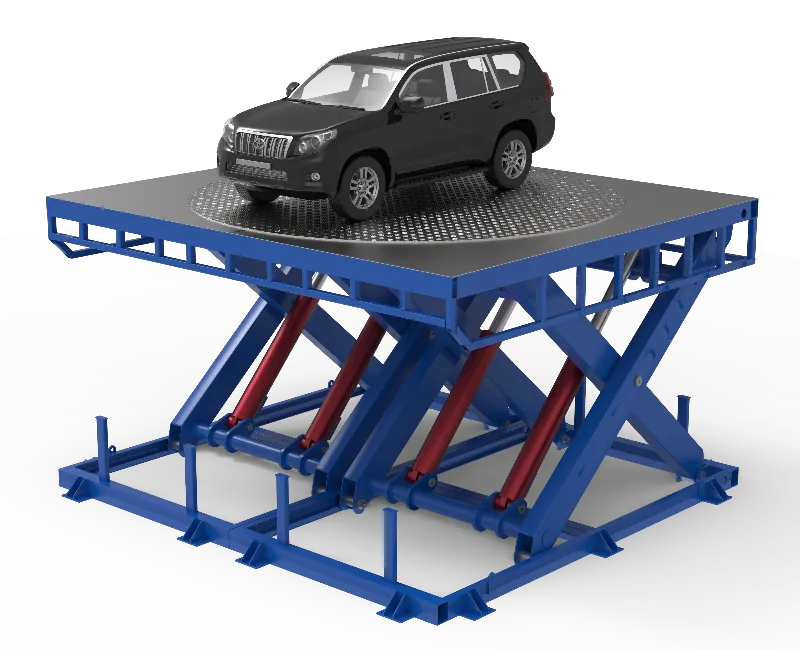

Turntable with Scissor Lift

This scissor lift is designed for scenes that require flexible operation. Its biggest highlight is the customizable rotating table, which breaks the limitation of traditional lifts that can only lift vertically and achieves 360-degree rotation, providing you with a more efficient and convenient high-altitude operation solution.

To find out more talk to our team

Specification

| Item | Description |

|---|---|

| Model | SRL-RT Series (Custom naming available) |

| Rated Load | 0.5-5 Tons (Higher capacity customizable) |

| Lifting Height | 2-12 Meters (Customizable higher range) |

| Table Size | Standard: 1.5m×2m (Custom diameter/rectangle up to 3m×4m) |

| Rotation | 360° Continuous rotation (adjustable speed: 0.5-2 rpm) |

| Drive System | Hydraulic lifting + Electric rotation (optional servo motor precision control) |

| Power Supply | 380V/50Hz 3-phase (Optional 220V or lithium battery) |

| Control | Wired control panel + Optional wireless remote (30m range) |

| Safety Features | Overload protection, emergency stop, rotation limit switch, anti-slip surface |

| Table Material | High-strength steel frame + anti-slip steel plate (optional aluminum/composite) |

| Equipment Weight | Approx. 800-3,000 kg (Customizable based on configuration) |

Features

🔹 Customized table rotation: The table can be customized in size and load capacity according to actual needs, and is equipped with a 360-degree rotation function to improve work efficiency.

🔹 Stable and reliable: High-strength steel and precision welding technology are used, the structure is stable, the operation is smooth, and the operation is safe.

🔹 Easy to operate: Equipped with a user-friendly control panel, the operation is simple and easy to understand, even non-professionals can quickly get started.

🔹 Safety function: Equipped with safety mechanisms such as overload protection and emergency stop control to ensure the safety of the operator during lifting operations.

Enquire here

Options & Accessories

| Category | Option/Accessory | Description |

|---|---|---|

| Control & Operation | 1. Extended Wireless Remote Control | 100m remote range with multi-device coordination. |

| 2. Touchscreen Programmable Panel | Pre-set rotation paths and lifting sequences (e.g., auto-demo mode). | |

| 3. Servo Motor Precision Control Kit | ±0.1° rotation accuracy for fine adjustments. | |

| Safety Enhancements | 1. Laser Collision Sensors | Halts rotation/lifting upon obstacle detection. |

| 2. Dual Brake Rotation Lock | Mechanical + electromagnetic locks for accidental rotation prevention. | |

| 3. Tilt Alarm System | Triggers alerts if table tilts beyond 2°. | |

| Environmental Adaptability | 1. Anti-slip Rubber Surface Kit | Removable pads with μ≥0.8 friction for wet conditions. |

| 2. Weatherproof Cover | IP65-rated protection for outdoor use. | |

| 3. Low-temperature Heating System | Pre-heats hydraulics for operation in -30℃ environments. | |

| Smart Integration | 1. IoT Remote Monitoring Module | Cloud-based data tracking via mobile app. |

| 2. Automation Script Interface | Open API for Python/LabVIEW integration. | |

| 3. Voice Control Module | Voice commands for lifting/rotation (CN/EN supported). |

Proud to supply material handling equipments to all industries and for all applications

The Material Handling Equipments in your industry

The Gradin goods lifts can be used to carry pallet loads of finished products or ingredients, or equipment, up and down from a mezzanine floor or second floor. The lift’s platform can be manufactured in stainless steel so it complies with regulations, is non-corrosive and can be washed.

With musculoskeletal injuries in mind, the following is a useful, but not exhaustive, list of situations that commonly arise in the manufacturing and engineering sectors during the production process:

• Repeated manipulation of the load at a distance from the trunk of the body.

• Repeated bending of the trunk to lift the load.

• A very large load that is difficult to grasp.

• Repeated handling of the load above shoulder height or at floor level.

• Lifting that involves twisting of the trunk.

• The load needs to be carried over a long distance through a cluttered or hazardous area.

When manual handling activities involve such risks of injury (particularly to the back) due to unfavourable ergonomic conditions, the basic principle is that the employer must take measures to reduce or eliminate the risk of injury.

The Gradin goods lift is designed specifically to transport standard sized pallets from manufacturing, to and from storage on a mezzanine or first floor. If a standard specification doesn’t tick all your boxes, we also specialise in bespoke configurations, working collaboratively with you to ensure your end solution is perfect for your company, employees and products.