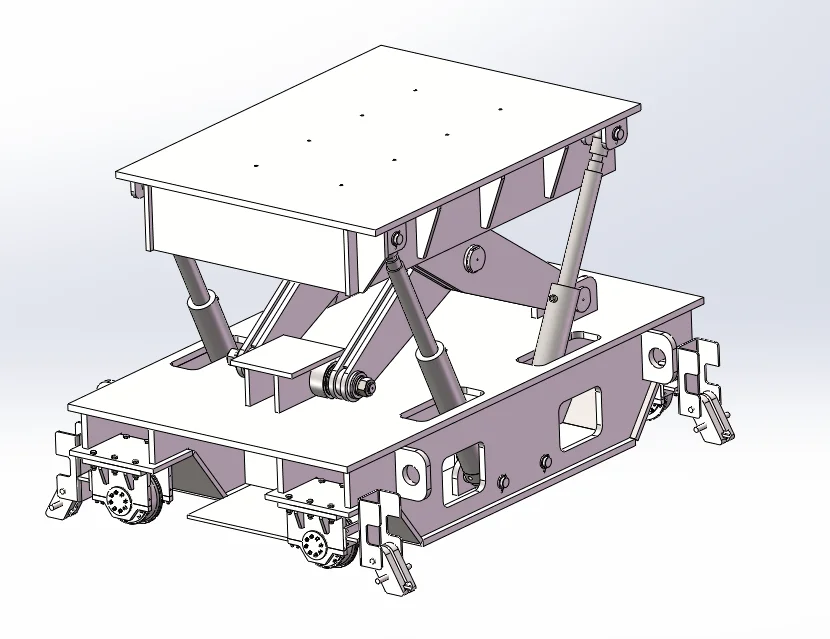

Rail-Guided Scissor Lift

This lift is specifically designed for the steel billet casting industry, featuring efficiency, safety, and durability. It is ideal for handling heavy materials in challenging industrial environments, with forward and backward movement along guide rails and button-controlled lifting operations to ensure stable performance.

To find out more talk to our team

Specification

| Item | Description |

|---|---|

| Model | SBL-HD Series |

| Rated Load | 5-20 Tons (Higher capacity customizable) |

| Lifting Height | 1-5 Meters (Customizable higher range) |

| Worktop Size | Standard: 2m×3m (Custom length/width up to 4m×6m) |

| Movement | Guided rail forward/backward movement (rail-powered or DC battery-driven) |

| Lifting Control | Push-button operation with jog/continuous modes |

| Power System | High-strength precision hydraulic cylinders (imported seals, high-pressure design) |

| Power Supply | Rail power: 380V/50Hz 3-phase; Independent: 24V/48V DC battery |

| Worktop Surface | High-quality baked paint finish; Optional stainless steel/corrosion-resistant coating |

| Safety Features | Fixed guardrails, hydraulic overload protection |

| Equipment Weight | Approx. 1,500-5,000 kg (Customizable based on load and size) |

Features

🔹 Equipped with a powered transport base, supporting both live rail and self-contained DC power supply.

🔹 Features safety guardrails to effectively prevent accidental falls of operators.

🔹 Utilizes high-strength precision hydraulic cylinders and imported sealing rings, enhancing equipment safety and longevity.

🔹 The worktop is finished with high-quality baked paint for rust and corrosion resistance, suitable for harsh industrial conditions.

Enquire here

Options & Accessories

| Category | Option/Accessory | Description |

|---|---|---|

| Control & Operation | 1. Wireless Remote Control System | Enables remote lifting/movement control within 50 meters. |

| 2. PLC Automation Module | Pre-programmed lifting cycles (e.g., timed operations, position memory). | |

| 3. Multilingual Interface | Touchscreen supports Chinese/English/French/Spanish for global teams. | |

| Safety Enhancements | 1. Infrared Anti-collision Sensors | Automatically halts movement upon obstacle detection. |

| 2. Dual Hydraulic Safety Locks | Redundant locks to prevent accidental lowering. | |

| 3. Manual Emergency Descent Pump | Safely lowers the platform during power outages. | |

| Environmental Adaptability | 1. High-temperature Worktop (800°C) | Ceramic-coated or Special Steel Plate for direct contact with hot billets. |

| 2. Dust-proof Sealing Kit | Protects hydraulic systems from metal dust ingress. | |

| 3. Anti-corrosion Coating (Optional) | Stainless steel/polyurethane coating for acid/alkali resistance. | |

| Mobility & Power | 1. Omnidirectional Drive Wheels | Replaces rails for free movement in trackless environments. |

| 2. High-capacity Lithium Battery | Extends DC operation to 8 hours (standard: 4 hours). | |

| 3. Fast Charging System | Charges to 80% in 1 hour, compatible with industrial chargers. | |

| Data & Monitoring | 1. Real-time Load Monitoring | Digital display shows weight, tilt angle, and hydraulic pressure. |

| 2. Black Box Data Logger | Records operational data (e.g., lift cycles, peak loads) for maintenance. | |

| 3. IoT Remote Diagnostics | 4G/5G-enabled cloud alerts for predictive maintenance. |

Proud to supply material handling equipments to all industries and for all applications

The Material Handling Equipments in your industry

The Gradin goods lifts can be used to carry pallet loads of finished products or ingredients, or equipment, up and down from a mezzanine floor or second floor. The lift’s platform can be manufactured in stainless steel so it complies with regulations, is non-corrosive and can be washed.

With musculoskeletal injuries in mind, the following is a useful, but not exhaustive, list of situations that commonly arise in the manufacturing and engineering sectors during the production process:

• Repeated manipulation of the load at a distance from the trunk of the body.

• Repeated bending of the trunk to lift the load.

• A very large load that is difficult to grasp.

• Repeated handling of the load above shoulder height or at floor level.

• Lifting that involves twisting of the trunk.

• The load needs to be carried over a long distance through a cluttered or hazardous area.

When manual handling activities involve such risks of injury (particularly to the back) due to unfavourable ergonomic conditions, the basic principle is that the employer must take measures to reduce or eliminate the risk of injury.

The Gradin goods lift is designed specifically to transport standard sized pallets from manufacturing, to and from storage on a mezzanine or first floor. If a standard specification doesn’t tick all your boxes, we also specialise in bespoke configurations, working collaboratively with you to ensure your end solution is perfect for your company, employees and products.